MAINTENANCE

STUMP GRINDERS

9778 7-29-14-3

REPLACING GEARBOX

When replacing the gearbox the unit should be either securely blocked up off the ground

or attached to a hoist with the hydraulic couplers disconnected. NOTE: A new cotter pin

should be installed whenever the wheel has been removed.

1. With the wheel guard cover removed, remove the castle nut and cotter pin securing the

wheel to the gearbox.

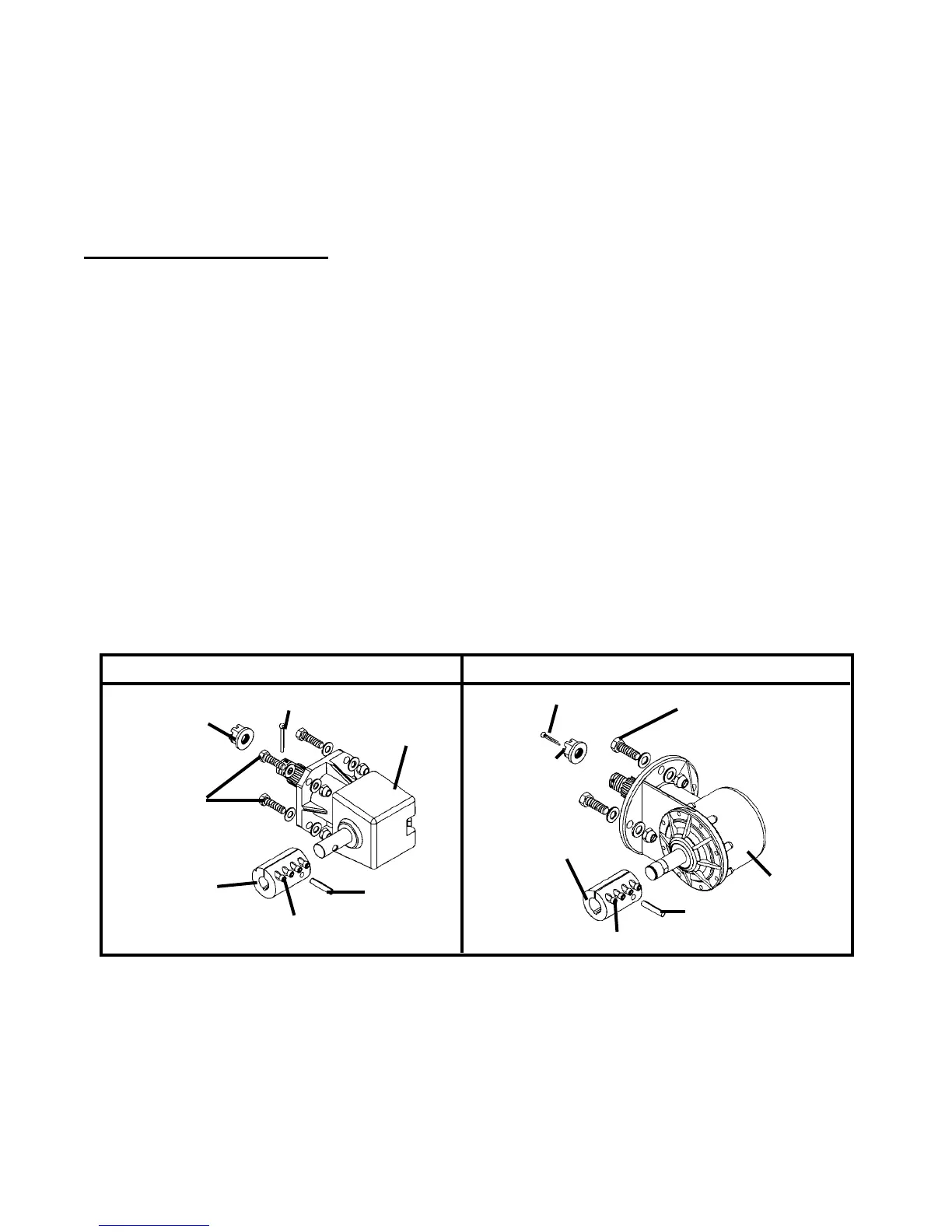

2. Loosenthefoursocketheadcapscrewsonthecoupler.SeeFigure#1

3. Standard Flow: Slidethemotoroutofthecoupler.SeeFigure#1

High Flow:Removethefour.50"capscrewsholdingthemotortothemotormounts

andslidethemotoroutofthecoupler.SeeFigure#1

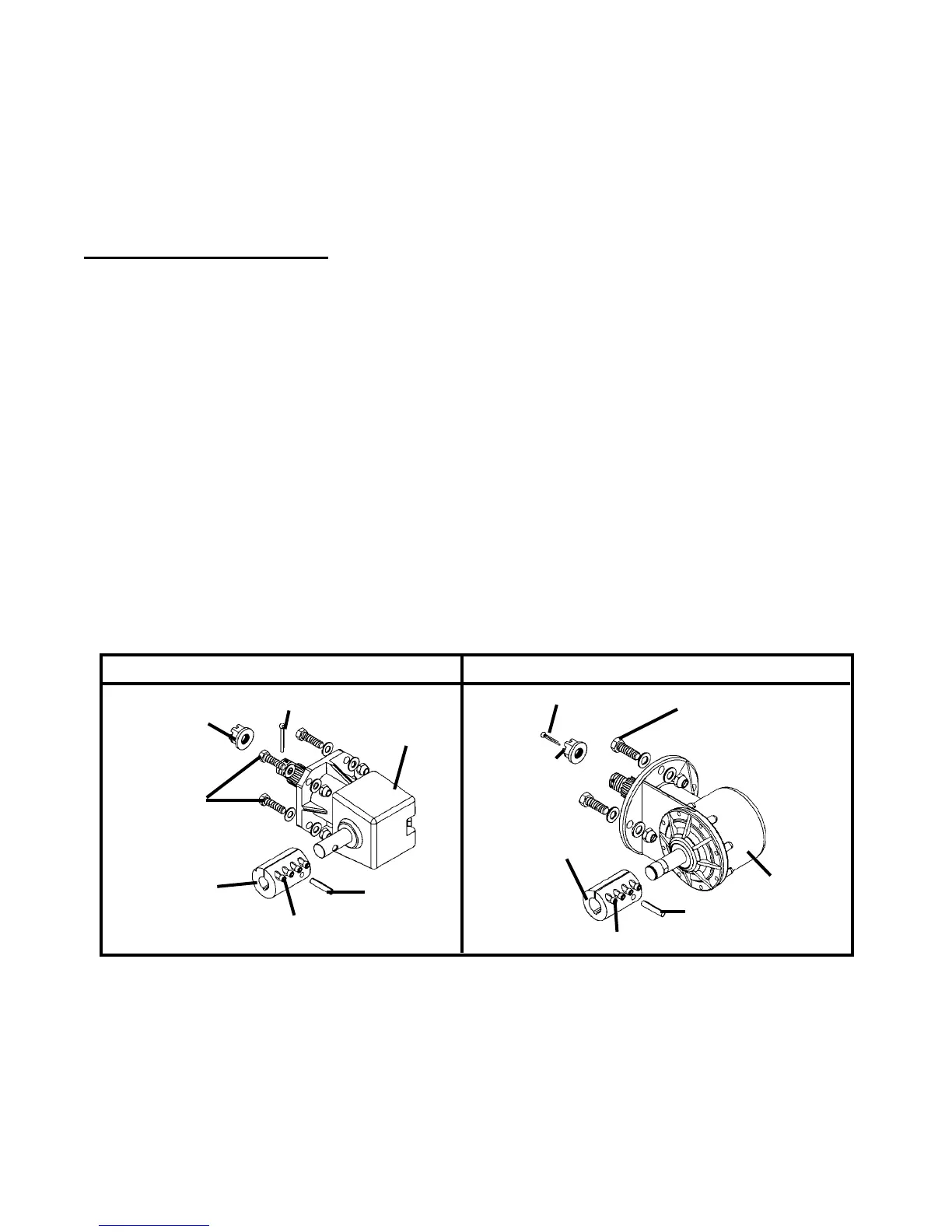

3. Removetherollpinholdingthecouplertothegearboxandremovethecoupler.See

Figure#2

4. Remove the four capscrews securing the gearbox to the stump grinder frame and re-

movethegearbox.SeeFigure#2 NOTE: Be prepared for the gearbox to drop

when the capscrews are removed.

5. Checklubricationlevelinthegearboxandaddasneeded.SeeSectionHInstallintothe

stump grinder frame using the existing hardware.

6. Place the new coupler on the gearbox shaft and reinstall the roll pin.

7. Reinstallthemotorintothecoupler(installthefour.50"capscrewsonhighowunits)

and retighten the sockethead capscrews.

8. Re-install the wheel using the new castle nut and cotter pin.

9. Re-install the wheel guard cover using the existing hardware.

10. Torqueallcapscrewstospecication.BoltTorqueSpecications

HIGH FLOW

ROLL PIN

GEARBOX

SOCKETHEAD CAPSCREWS

CASTLE

NUT

CASTLE

NUT

STANDARD FLOW

GEARBOX

COTTER PIN

FIGURE #2

ROLL PIN

SOCKETHEAD CAPSCREWS

COTTER PIN

COUPLER

CAPSCREWS SECURING

GEARBOX TO STUMP

GRINDER FRAME

COUPLER

CAPSCREWS

SECURING GEARBOX

TO STUMP GRINDER

FRAME

5. Reinstallthemotorintothecoupler(installthefour.50"capscrewsonhighowunits)

andretightenthesocketheadcapscrews.Torquetospecication.BoltTorqueSpecica-

tions

Loading...

Loading...