MAINTENANCE

STUMP GRINDERS

9777 7-29-14-3

4. Standard Flow: Install the new motor onto the motor mount using the existing hard-

ware.Slidethemotorwiththemountingplateintothecouplerwhilepositioningtherub-

ber bumpers and retighten the sockethead capscrews.

High Flow:Slidethemotorintothecouplerwhilemaintainingthepositioningofthe

motor mounting plates. Reinstall the motor onto the motor mountings using the existing

hardware and retighten the sockethead capscrews.

WARNING! Avoid serious injury. Lower the stump grinder to the ground, set the park-

ing brake, stop the skid steer engine and remove the key before leaving the

operator's seat. If unit must be left raised for maintenance block the unit

securely to prevent accidental release of the lifting mechanism. Disconnect

the hydraulic couplers.

REPLACING GEARBOX/MOTOR COUPLER

When replacing the coupler the unit should be either securely blocked up off the ground

or attached to a hoist with the hydraulic couplers disconnected.

1. With unit securely positioned and hydraulic couplers disconnected, loosen the four

sockethead capscrews on the coupler.

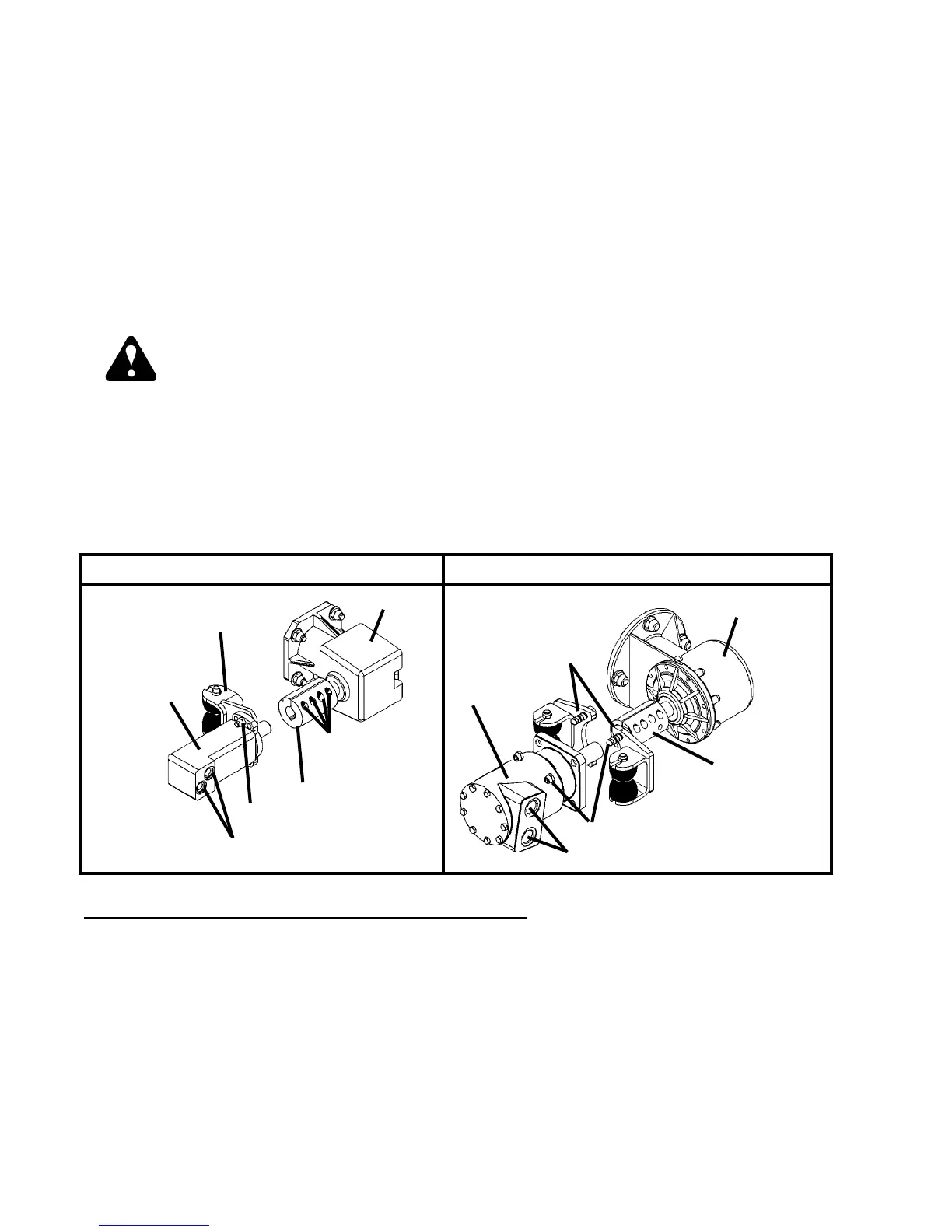

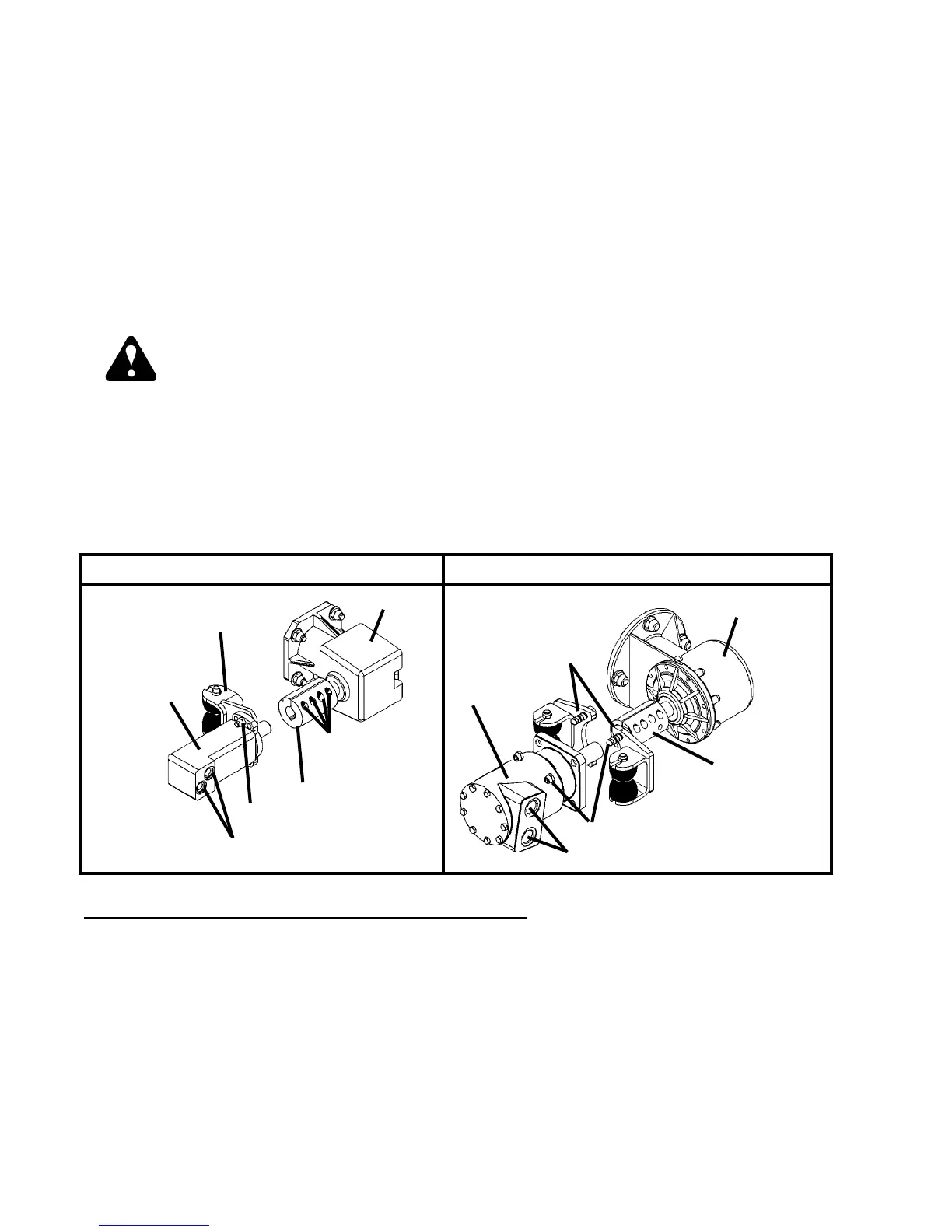

2. Standard Flow:Slidethemotoroutofthecoupler.SeeFigure#1

High Flow:Removethefour.50"capscrewsholdingthemotortothemotormounts

andslidethemotoroutofthecoupler.SeeFigure#1

3. Remove the roll pin holding the coupler to the gearbox.

4. Place the new coupler on the gearbox shaft and reinstall the roll pin.

HIGH FLOW

TAG HYDRAULIC HOSES

MOTOR

COUPLER

GEARBOX

SOCKETHEAD

CAPSCREWS

MOTOR

MOUNT

MOTOR

MOUNTS

.50" X 1.75" CAPSCREW

MOTOR

STANDARD FLOW

GEARBOX

TAG HYDRAULIC HOSES

FIGURE #1

5. Torqueallhardwaretospecication.SeeBoltTorqueSpecications

6. Re-connectthehydraulichosesandttingstothenewmotor.

7. Check for leaks and tighten as required.

.50" X 2.25" CAPSCREWS & NUTS

Loading...

Loading...