Lubrication

between

the ouside of the quill and the bore in

which

it rides

is

effected by

waste

oil

from

the

Z

axis ballscrew.

To distribute and retain the oil on

the

table,

saddle and

knee, grooves

are

cut

into the

face

of

the

ways

and through holes

in

the

gib

so

that both

sides

of

the dovetail

get full

lubrication.

Excess oil exudes

over the

edge

of the

ways

between

the moving members.

Spindle bearings are

grease-packed

and require no

additional lubrication

for

the

life of the

machine.

Low level lube

will not stop a

job

in

progress

but it

will

prwent the

feed

from

being

started

for

the next

job.

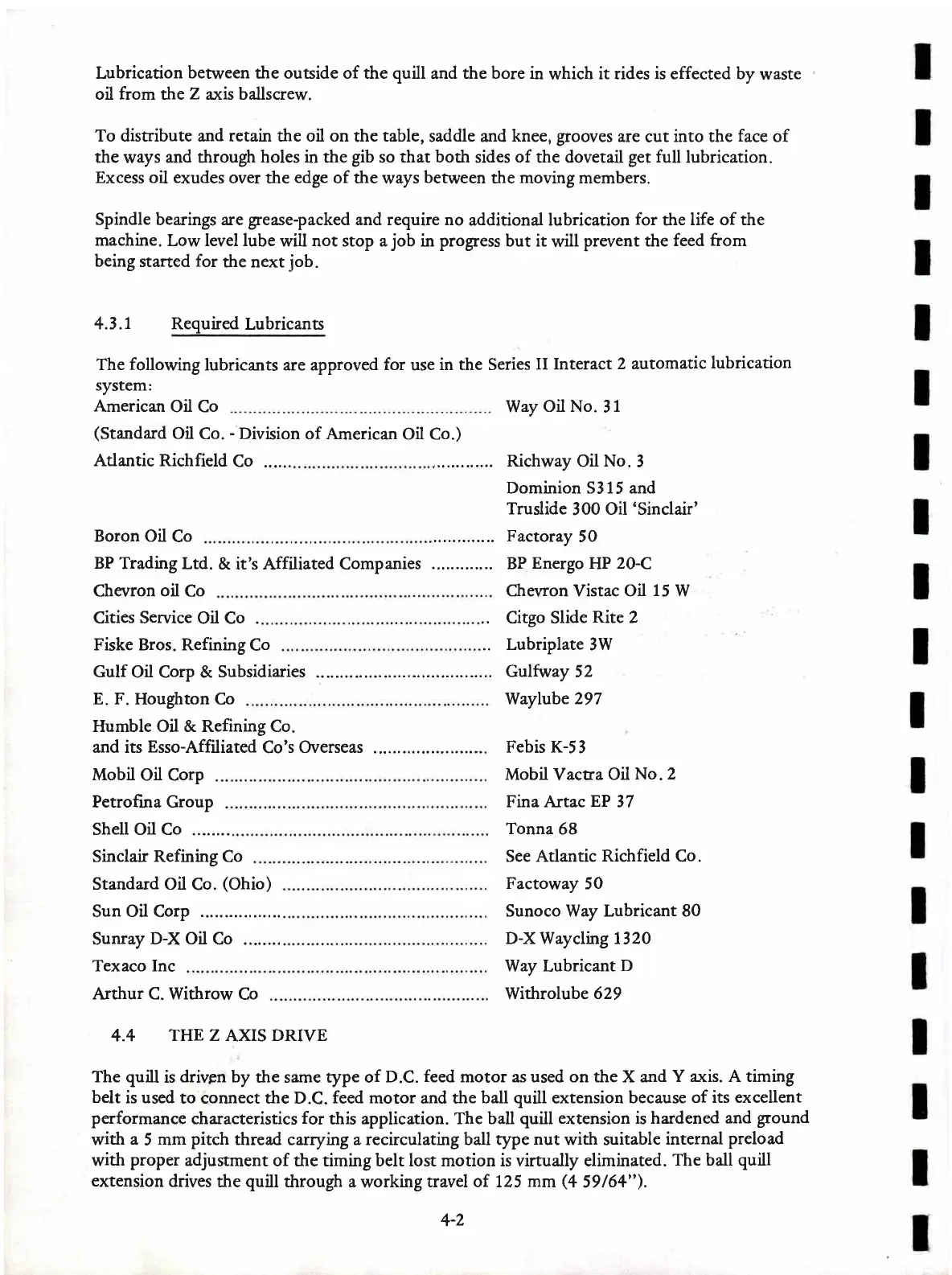

4.3.7 RequiredLubricants

The

following

lubricants are approved

for

use

in the Series

II Interact

2 automatic

lubrication

system:

American Oil Co

(Standard

Oil

Co.

-

Division of American

Oil Co.)

Adantic Richfield

Co

......

Boron Oil Co

Shell Oil Co

........

Sinclair Refining Co

Standard Oil

Co.

(Ohio)

Sun Oil Corp ........

Sunray

D-X Oil

Co ........

Way

Oil

No.

31

Richway

Oil

No.

3

Dominion 5315 and

Truslide

300

Oil'Sinclair'

Factoray

5O

Febis

K-5

3

Mobil

Vactra

Oil

No.2

Fina Artac

EP

37

Tonna

68

See

Atlantic

Richfield

Co.

Factoway

50

Sunoco Way Lubricant 80

D-X Wayclingl32O

Way Lubricant

D

Withrolube

629

BP

Trading Ltd.

& it's Affiliated Companies

............. BP

Energo

HP

20-C

Chevron

oil

Co

Chewon Vistac Oil

15

W

Cities Service

Oil Co ..

Citgo Slide

Rite

2

Fiske Bros. Refining

Co

..

Lubriplate

3W

Gulf

Oil Corp &

Subsidiaries

Gulfway

52

E. F.

Houghton Co

Waylube

297

Humble Oil & Refining Co

and its

Esso-Affiliated

Co's

Oyerseas

Mobil

Oil Corp

Petrofina Group

Texaco Inc

Arthur C. Withrow

Co

4.4 THE Z AXIS DRIVE

The quill

is

drivpn by

the same type of

D.C.

feed

motor as used on the X and

Y u<is. A timing

belt

is used

to connect the D.C.

feed

motor and the

ball quill

extension

because

of its excellent

performance

characteristics

for

this

application. The ball

quill extension is hardened

and

ground

with a

5

mm

pitch

thread carryng a recirculating ball type

nut

with suitable

internal

preload

with

proper

adjustment

of the timing belt lost motion is virnrally eliminated.

The ball quill

extension

drives

the

quill

through a

working

travel of.725

mm

(4

59/6+").

4-2

Loading...

Loading...