2-1

OPERATION

SAFETY RULES

GENERAL:

1. Since the manufacturer has no direct control over machine application and

operation, conformance with good safety practice is the responsibility of the user and

his operating personnel.

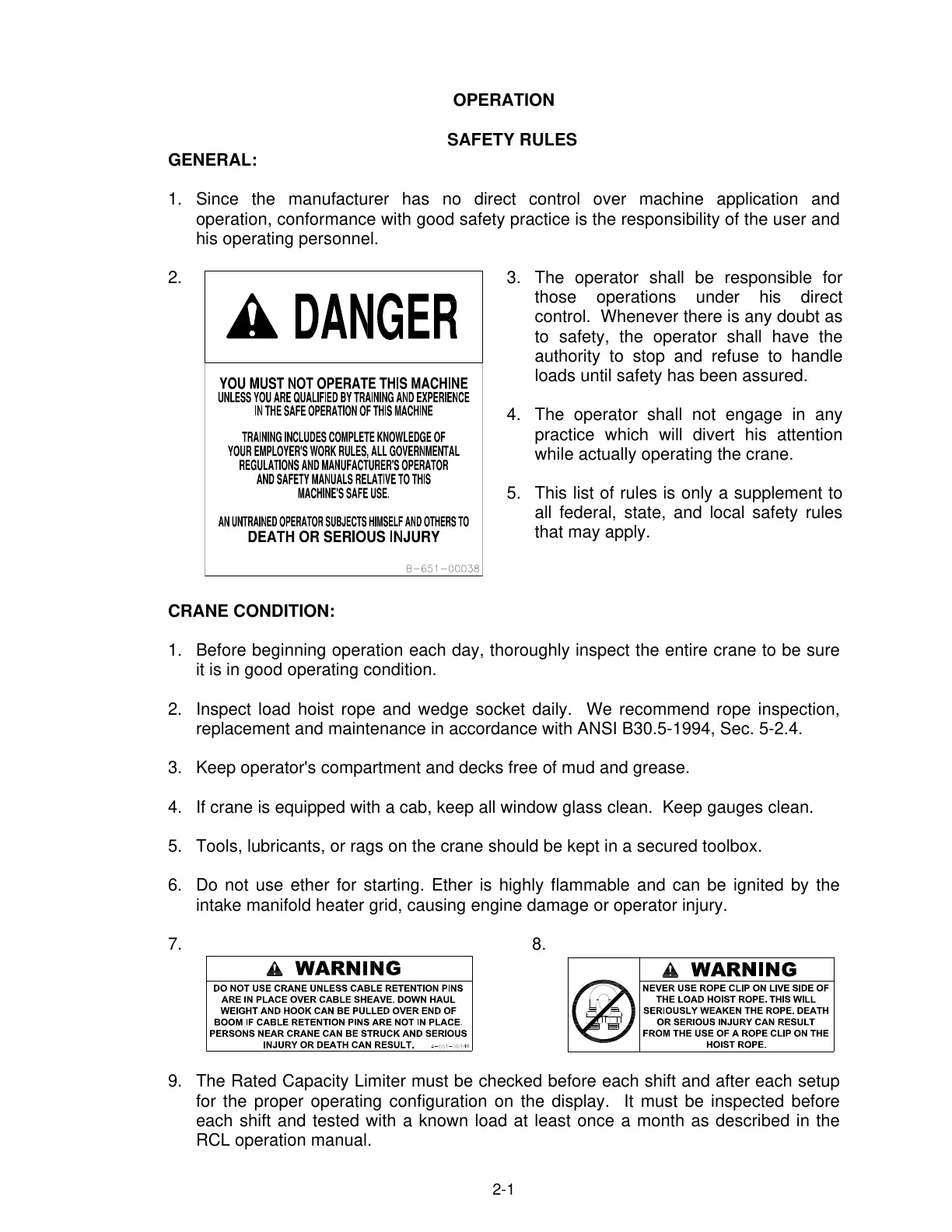

2.

3. The operator shall be responsible for

those operations under his direct

control. Whenever there is any doubt as

to safety, the operator shall have the

authority to stop and refuse to handle

loads until safety has been assured.

4. The operator shall not engage in any

practice which will divert his attention

while actually operating the crane.

5. This list of rules is only a supplement to

all federal, state, and local safety rules

that may apply.

CRANE CONDITION:

1. Before beginning operation each day, thoroughly inspect the entire crane to be sure

it is in good operating condition.

2. Inspect load hoist rope and wedge socket daily. We recommend rope inspection,

replacement and maintenance in accordance with ANSI B30.5-1994, Sec. 5-2.4.

3. Keep operator's compartment and decks free of mud and grease.

4. If crane is equipped with a cab, keep all window glass clean. Keep gauges clean.

5. Tools, lubricants, or rags on the crane should be kept in a secured toolbox.

6. Do not use ether for starting. Ether is highly flammable and can be ignited by the

intake manifold heater grid, causing engine damage or operator injury.

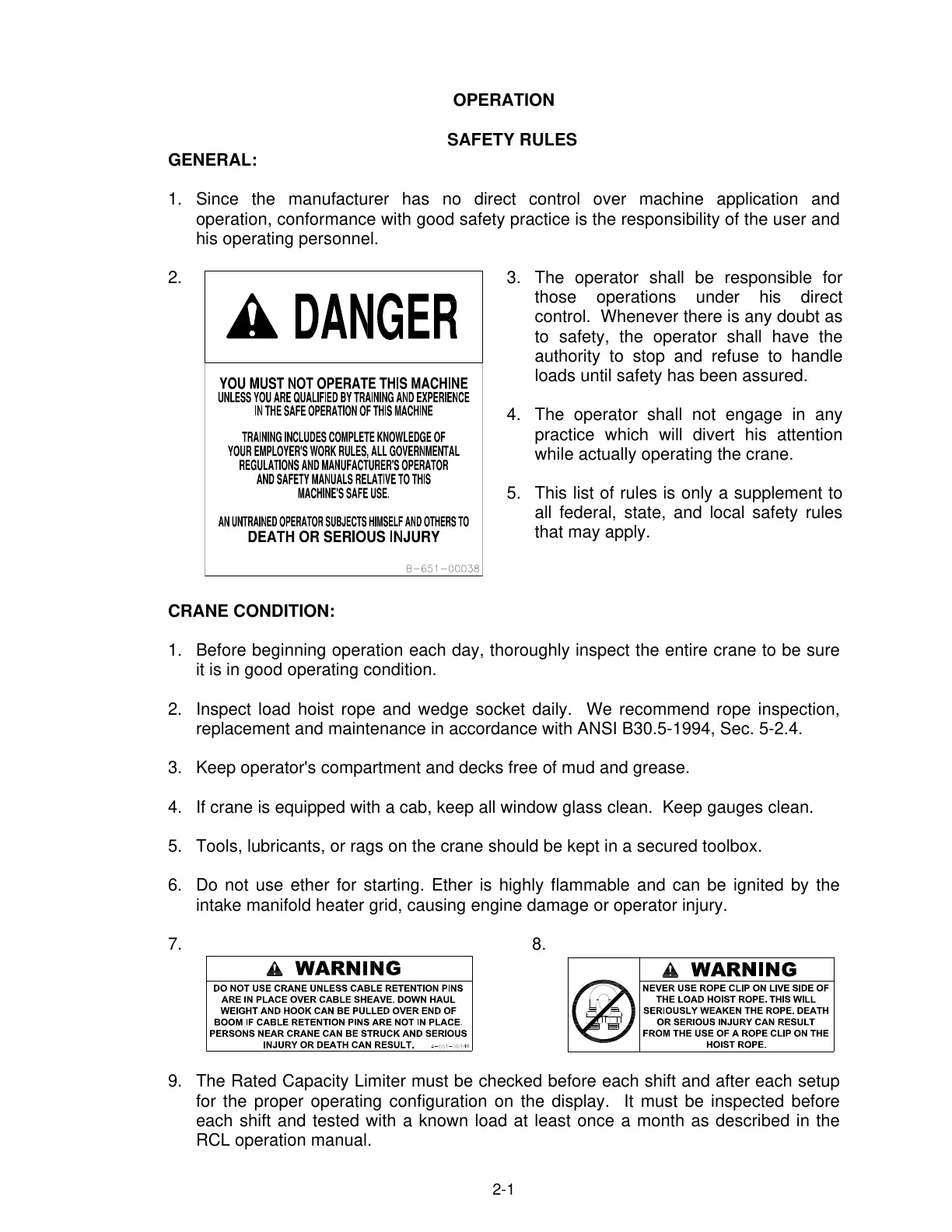

7. 8.

9. The Rated Capacity Limiter must be checked before each shift and after each setup

for the proper operating configuration on the display. It must be inspected before

each shift and tested with a known load at least once a month as described in the

RCL operation manual.

Courtesy of Crane.Market

Loading...

Loading...