INSPECTION AND MAINTENANCE70

10

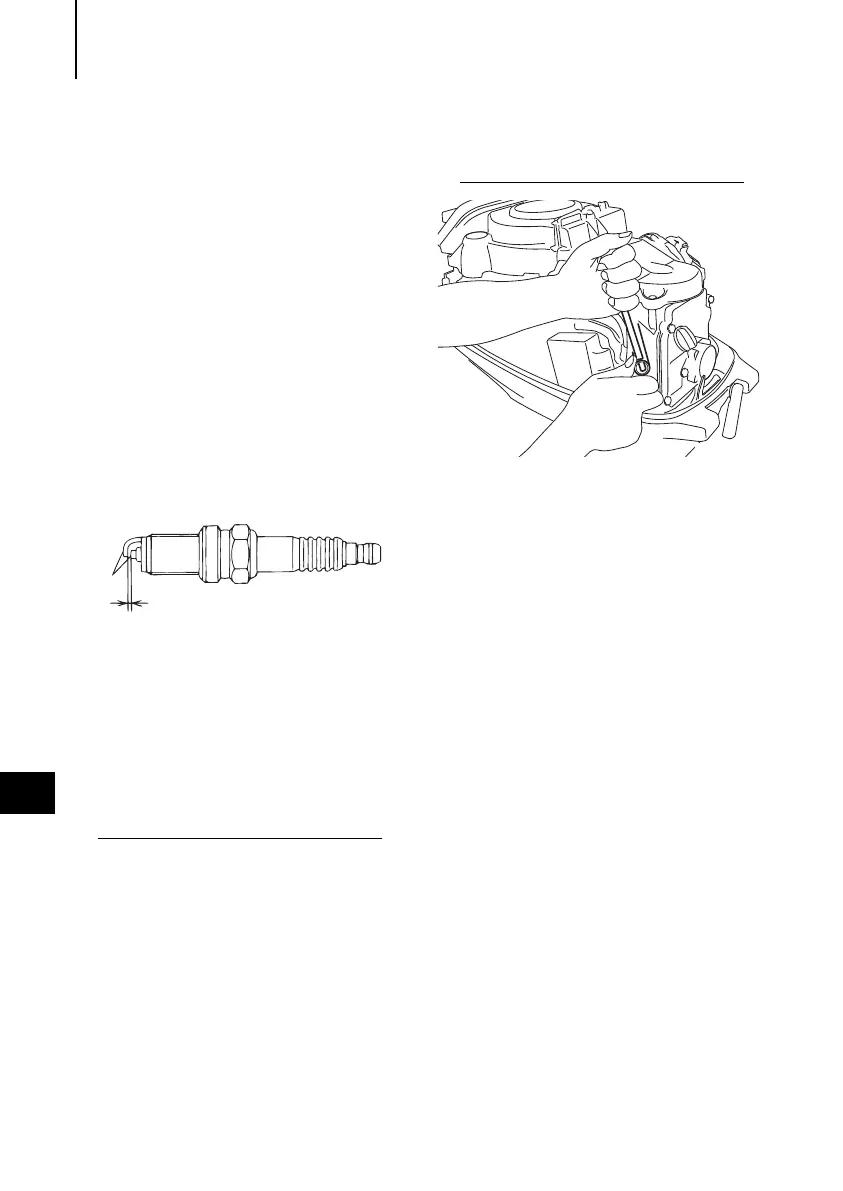

4. Remove the spark plugs by turning it

counter-clockwise, using a 5/8" (16

mm) socket wrench and handle that is

provided in tool bag.

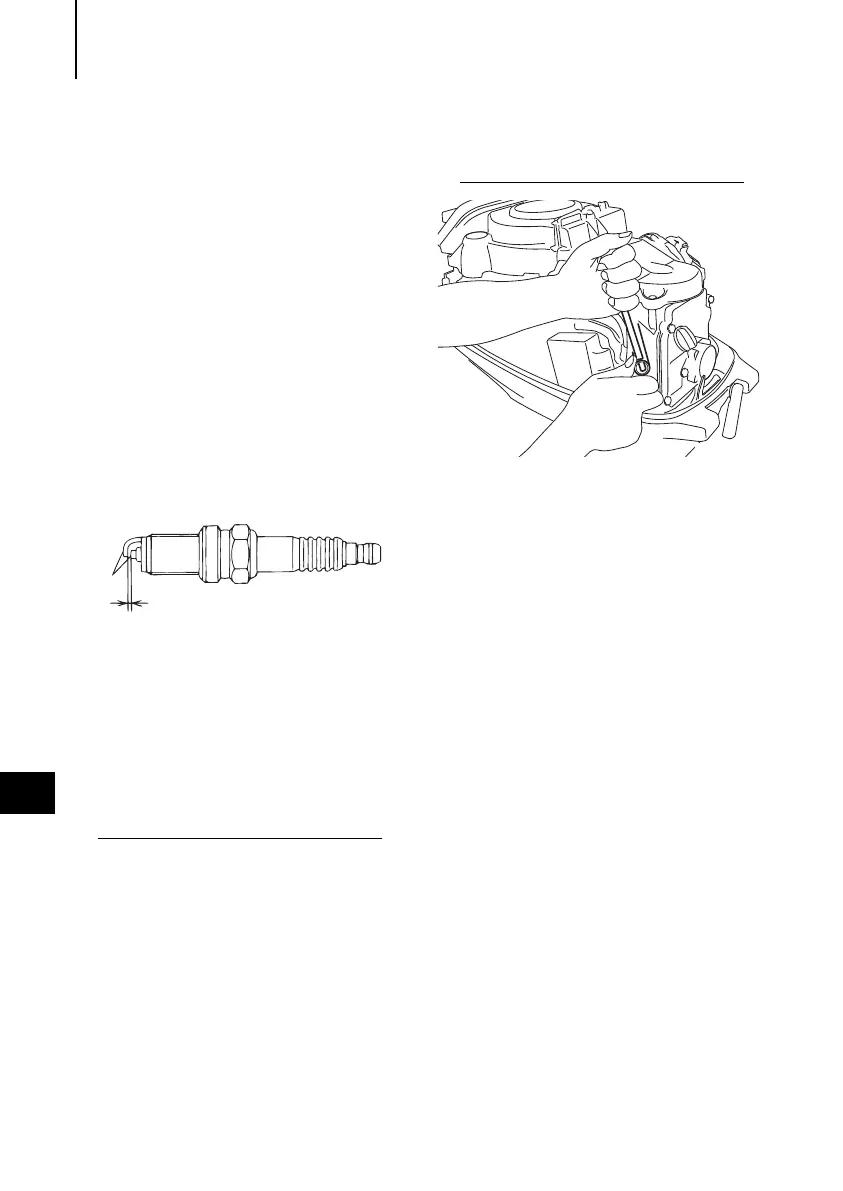

5. Inspect the spark plug. Replace the

spark plug if the electrodes are worn or

if t h e i n s u l a t o r s a r e c r a c k e d o r

chipped.

6. Measure the spark plug electrode gap

with a wire type feeler gauge. The gap

should be 0.8-0.9 mm (0.031-0.035

inches). If the gap is different, replace

the spark plug with a new one

Use spark plug NGK DCPR-6E.

1. Electrode

2. Spark gap (0.8–0.9 mm, 0.031–0.035 in)

7. Install the spark plug by hand and turn

it carefully to avoid cross-threading.

8. Tighten the spark plug to the specified

torque.

ENON00028-0

Note

Spark plug torque:

18.0 Nm (13.3 ft-lb) [1.84 kgf-m]

If a torque-wrench is not available when you

are fitting a spark plug, a good estimate of

the correct torque is 1/4 to 1/2 a turn past

finger-tight. Have the spark plug adjusted to

the correct torque as soon as possible with

a torque-wrench.

1

2

ENOF00085-0

E15__US_EN_141125N.book 70 ページ 2014年12月26日 金曜日 午後2時46分

Loading...

Loading...