22

COMPRESSORS

Lubrication

Compressors are charged with the correct amount of oil at the

factory.

Replacing the Compressor

The compressor using Puron

®

refrigerant contains a POE oil. This

oil has a high affinity for moisture. Do not remove the compres-

sor’s tube plugs until ready to insert the unit suction and discharge

tube line ends.

NOTE: Only factory-trained service technicians should remove

and replace compressor units.

COMPRESSOR MOUNTING BOLTS

Compressor mounting bolts should be periodically inspected for

proper tightness. Bolts should be tightened and have the torque set

at 65 to 75 in.-lb (7.3 to 8.5 Nm).

COMPRESSOR ROTATION

On 3-phase units with scroll compressors, it is important to be cer-

tain compressor is rotating in the proper direction. To determine

whether the compressor is rotating in the proper direction:

1. Connect service gages to suction and discharge pressure

fittings.

2. Energize the compressor.

3. The suction pressure should drop and the discharge pres-

sure should rise, as is normal on any start-up.

NOTE: If the suction pressure does not drop and the discharge

pressure does not rise to normal levels.

4. Note that the evaporator fan is probably also rotating in

the wrong direction.

5. Turn off power to the unit. Use applicable lockout/tag-out

procedures.

6. Reverse any two of the unit power leads.

7. Reapply power to the compressor.

The suction and discharge pressure levels should now move to

their normal start-up levels.

NOTE: When the compressor is rotating in the wrong direction,

the unit makes an elevated level of noise and does not provide

cooling.

Filter Drier

Replace the filter drier whenever refrigerant system is exposed to

atmosphere. Only use factory specified liquid-line filter driers

with working pressures no less than 650 psig (4482 kPa). Do not

install a suction-line filter drier in a liquid line. A liquid-line filter

drier is designed for use with Puron (R-410A) refrigerant and is

required on every unit.

REPLACING THE FILTER DRIER

Use the following steps to replace the filter drier.

1. Using Puron (R-410A) gage set, recover all refrigerant

from system.

2. Use tubing cutter to remove filter drier from line.

NOTE: Do not use a torch to remove old filter drier. The heat from

the torch will allow contaminants into the air and into the open re-

frigeration system.

3. Sweat a new replacement filter drier into refrigerant line.

4. Re-charge refrigerant system.

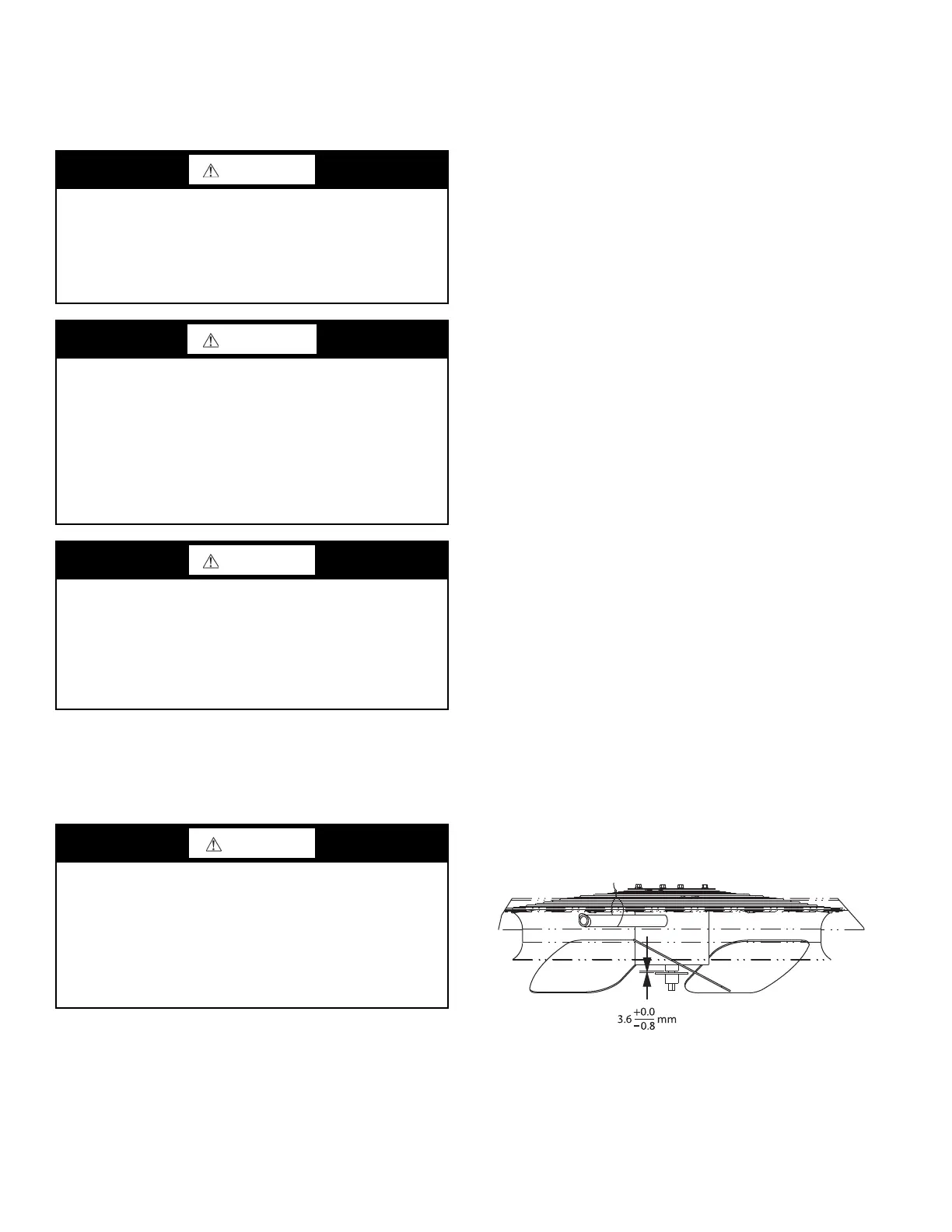

Adjusting the Condenser-Fan

1. Shut off unit power supply. Apply appropriate lockout/tag-

out procedures.

2. Remove condenser-fan assembly (grille, motor, and fan).

3. Loosen fan hub setscrews.

4. Adjust fan height as shown in Fig. 25.

5. Tighten setscrews to 84 in.-lb (9.5 Nm).

6. Replace condenser-fan assembly.

Fig. 25 — Condenser Fan Adjustment

TROUBLESHOOTING COOLING SYSTEM

Troubleshooting Cooling System

Refer to Table 5 for Troubleshooting Cooling System topics.

WARNING

FIRE, EXPLOSION HAZARD

Failure to follow this warning could result in death, serious

personal injury and/or property damage.

Never use air or gases containing oxygen for leak testing or for

operating refrigerant compressors. Pressurized mixtures of air

or gases containing oxygen can lead to an explosion.

WARNING

PERSONAL INJURY AND ENVIRONMENTAL

HAZARD

Failure to follow this warning could cause personal injury or

death.

Relieve pressure and recover all refrigerant before system re-

pair or final unit disposal.

Wear safety glasses and gloves when handling refrigerants.

Keep torches and other ignition sources away from refriger-

ants and oils.

WARNING

FIRE, EXPLOSION HAZARD

Failure to follow this warning could result in death, serious

personal injury and/or property damage.

Never use non-certified refrigerants in this product. Non-certi-

fied refrigerants could contain contaminates that could lead to

unsafe operating conditions. Use ONLY refrigerants that con-

form to AHRI Standard 700.

CAUTION

UNIT DAMAGE HAZARD

Failure to follow this caution may result in damage to compo-

nents.

The compressor is in a R-410A refrigerant system and uses a

polyolester (POE) oil. This oil is extremely hygroscopic,

meaning it absorbs water readily. POE oils can absorb

15 times as much water as other oils designed for HCFC and

CFC refrigerants. Avoid exposure of the oil to the atmosphere.

Loading...

Loading...