33

Gas line pressure entering the unit’s main gas valve must be within

specified ranges. See Table 9. Adjust unit gas regulator valve as

required or consult local gas utility.

Manifold pressure is factory-adjusted for NG fuel use. Adjust as

required to obtain best flame characteristic. See Table 10.

LIQUID PROPANE

Accessory packages are available for field-installation that will

convert the 581J unit to operate with liquid propane (LP) fuels.

These kits include new orifice spuds, new springs for gas valves

and a supply line low pressure switch. See section on Orifice Re-

placement on page 37 for details on orifice size selections.

Fuel line pressure entering unit gas valve must remain within

specified range. See Table 11.

Manifold pressure for LP fuel use must be adjusted to specified

range. See Table 12. Follow instructions in the accessory kit to

make initial readjustment.

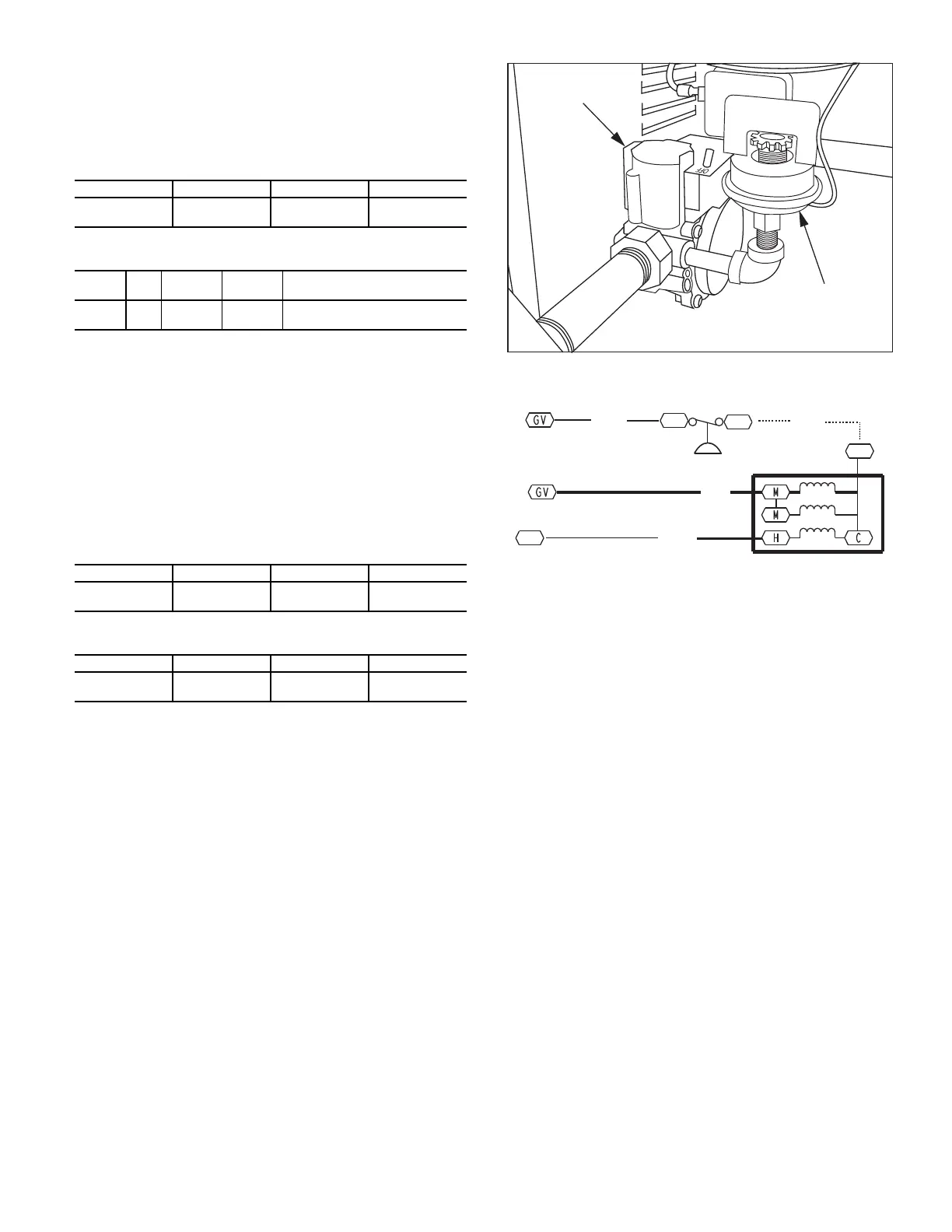

SUPPLY PRESSURE SWITCH

The LP conversion kit includes a supply low pressure switch. The

switch contacts (from terminal C to terminal NO [Normally

Open]) will open the gas valve power whenever the supply line

pressure drops below the setpoint. See Fig. 41 and 42. The switch,

HK02LB008, opens contacts on pressure “fall” at 7.2 in. wg

± 0.70 in. wg. Contacts close on pressure rise above 10.2 in. wg. If

the low pressure remains open for 15 minutes during a call for

heat, the IGC circuit will initiate a Ignition Fault (5 flashes) lock-

out. Reset of the low pressure switch is automatic on rise in supply

line pressure. Reset of the IGC requires a recycle of unit power af-

ter the low pressure switch has closed.

LIMIT SWITCH

Remove blower access panel. Limit switch is located on the fan

deck for sideshot units and on the vestibule plate for downshot

units. See Fig. 40.

This switch also prevents operation when the propane tank level is

low which can result in gas with a high concentration of impuri-

ties, additives, and residues that have settled to the bottom of the

tank. Operation under these conditions can cause harm to the heat

exchanger system. Contact your fuel supplier if this condition is

suspected.

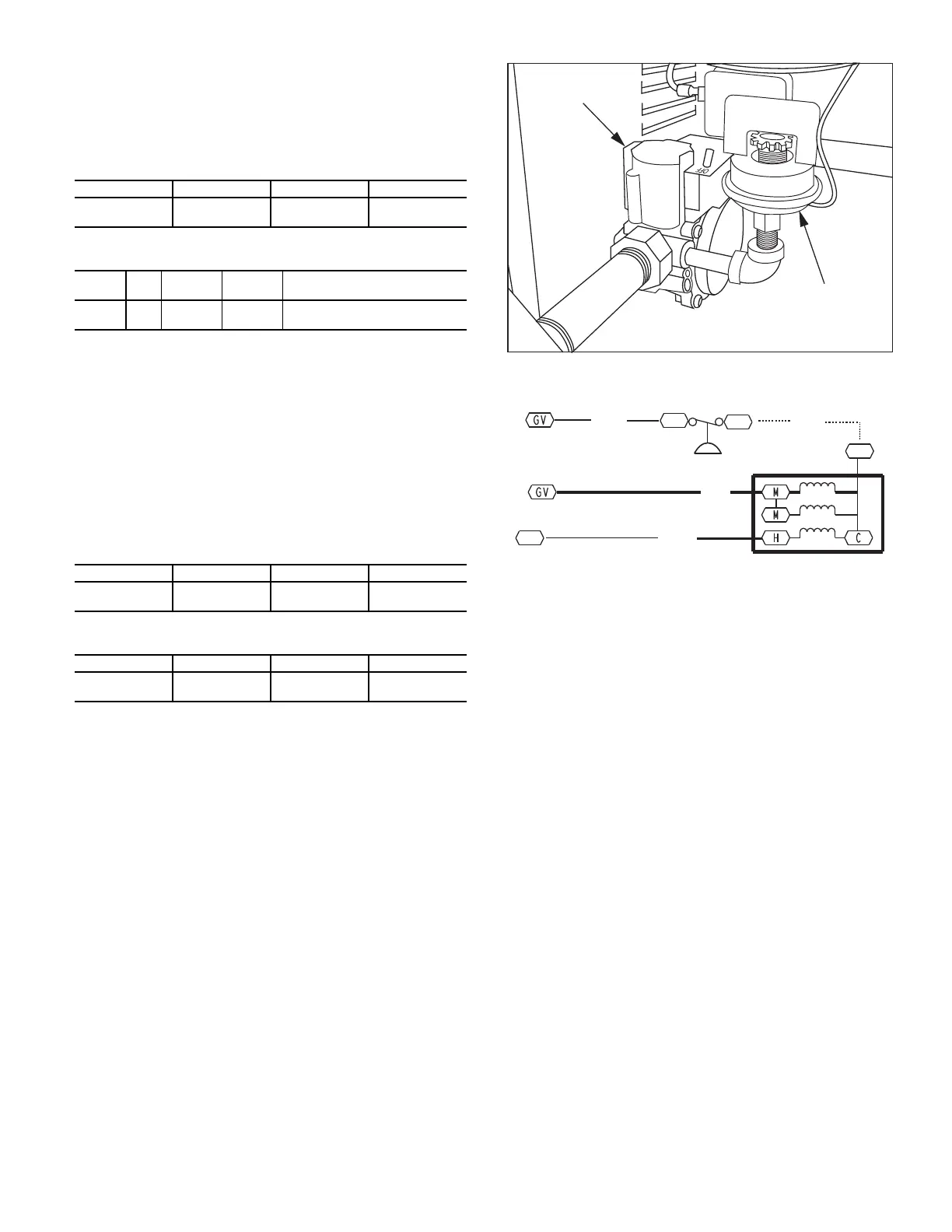

Fig. 41 — LP Low Pressure Switch (installed) for 581J*D

Fig. 42 — LP Supply Line Low Pressure Switch Wiring

Flue Gas Passageways

To inspect the flue collector box and upper areas of the heat

exchanger:

1. Remove the combustion blower wheel and motor assem-

bly according to directions in Combustion-Air Blower sec-

tion. See Fig. 43.

2. Remove the flue cover to inspect the heat exchanger.

3. Clean all surfaces as required using a wire brush.

Combustion-Air Blower

Clean periodically to assure proper airflow and heating efficiency.

Inspect blower wheel every fall and periodically during heating

season. For the first heating season, inspect blower wheel bi-

monthly to determine proper cleaning frequency.

To access burner section, open the heater access door below the

indoor fan panel.

To inspect blower wheel, shine a flashlight into draft hood open-

ing. If cleaning is required, remove motor and wheel as follows:

1. Remove the seven screws attaching the induced-draft

motor housing to the vestibule plate. See Fig. 43.

2. The blower wheel can be cleaned at this point. If additional

cleaning is required, continue with Steps 3 through 5.

3. Remove the blower from the motor shaft, by loosening

two setscrews.

4. Remove the motor by removing the four screws that hold

the motor to mounting plate. Remove the motor cooling

fan by removing one setscrew.

5. Remove the nuts that hold the motor to the mounting plate.

6. To reinstall, reverse the procedure outlined above.

Table 9 — Natural Gas Supply Line Pressure Ranges

UNIT MODEL UNIT SIZE MIN MAX

581J ALL

4.0 in. wg

(996 Pa)

13.0 in. wg

(3240 Pa)

Table 10 — Natural Gas Manifold Pressure Ranges

UNIT

MODEL

UNIT

SIZE

HIGH

FIRE

LOW

FIRE

RANGE

581J All 3.0 in. wg 2.0 in. wg

Reference MRT unit nameplate

for range ratings.

Table 11 — Liquid Propane Supply Line Pressure Ranges

UNIT MODEL UNIT SIZE MIN MAX

581J All

11.0 in. wg

(2740 Pa)

13.0 in. wg

(3240 Pa)

Table 12 — Liquid Propane Manifold Pressure Ranges

UNIT MODEL UNIT SIZE HIGH FIRE LOW FIRE

581J All

11.0 in. wg

(2740 Pa)

7.3 in. wg

(1820 Pa)

LP LOW PRESSURE

SWITCH

GAS VALVE

PNK

W2

TSTAT

GRA

BRN

IGC

J2-12

IGC

J2-11

BRN

C

NO

MGV

C

LP LPS

Loading...

Loading...