82

NOTE: Do not adjust pulley further than 5 turns open.

GENERAL FAN PERFORMANCE NOTES

1. Interpolation is permissible. Do not extrapolate.

2. External static pressure is the static pressure difference between the return duct and the supply duct plus the static pressure

caused by any FIOPs or accessories.

3. Tabular data accounts for pressure loss due to clean filters, unit casing, wet coils, and highest gas heat exchanger (when gas heat

unit).

4. Factory options and accessories may effect static pressure losses. Gas heat unit fan tables assume highest gas heat models; for

fan selections with low or medium heat models, the user must deduct low and medium heat static pressures. Selection software

is available, through your salesperson, to help you select the best motor/drive combination for your application.

5. The fan performance tables offer motor/drive recommendations. In cases when two motor/drive combinations would work,

Bryant recommends the lower horsepower option.

6. For information on the electrical properties of Bryant motors, please see the Electrical information section of this book.

7. For more information on the performance limits of Bryant motors, see the application data section of this book.

8. The EPACT (Energy Policy Act of 1992) regulates energy requirements for specific types of indoor fan motors. Motors regu-

lated by EPACT include any general purpose, T-frame (three-digit, 143 and larger), single-speed, foot mounted, polyphase,

squirrel cage induction motors of NEMA (National Electrical Manufacturers Association) design A and B, manufactured for use

in the United States. Ranging from 1 to 200 Hp, these continuous-duty motors operate on 230 and 460 volt, 60 Hz power. If a

motor does not fit into these specifications, the motor does not have to be replaced by an EPACT compliant energy-efficient

motor. Variable-speed motors are exempt from EPACT compliance requirements.

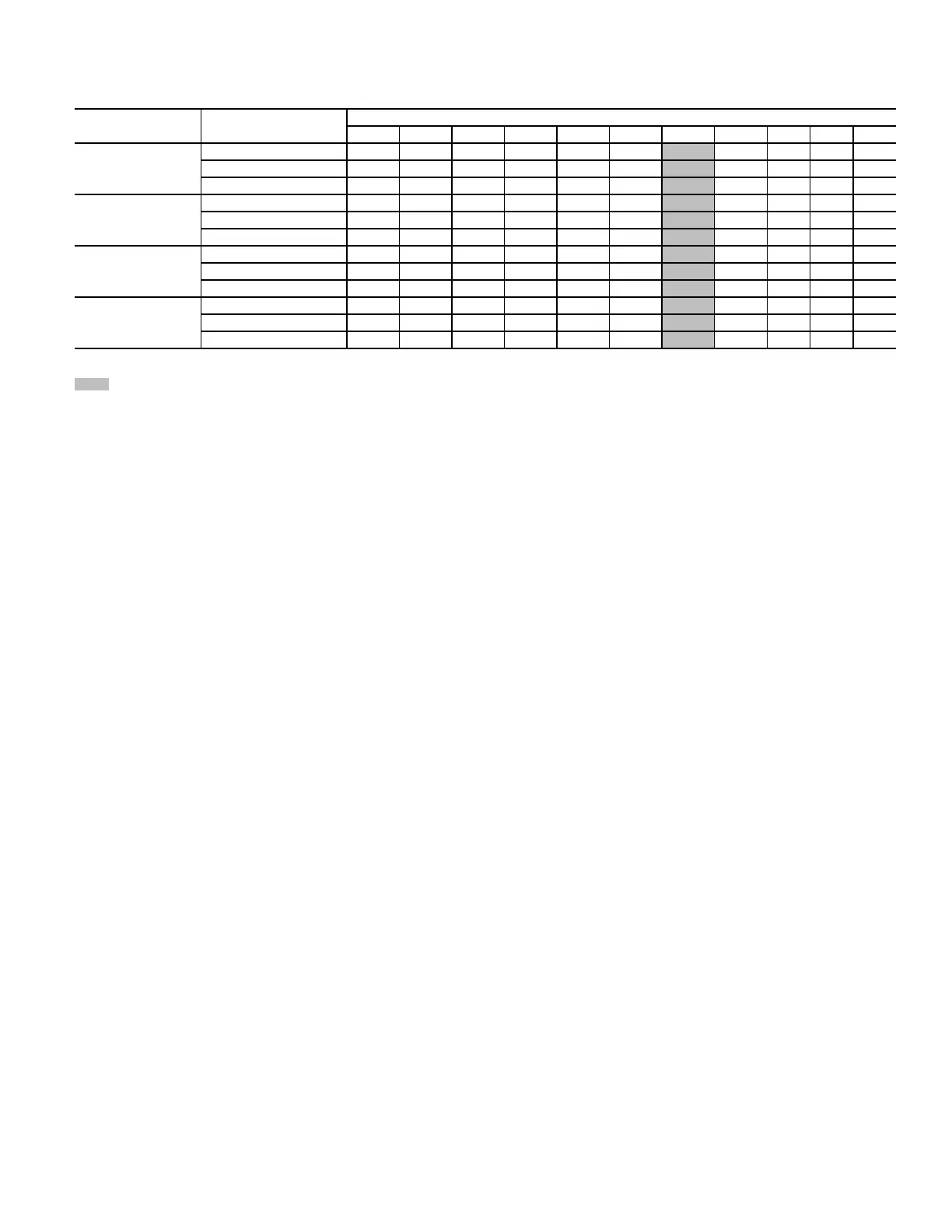

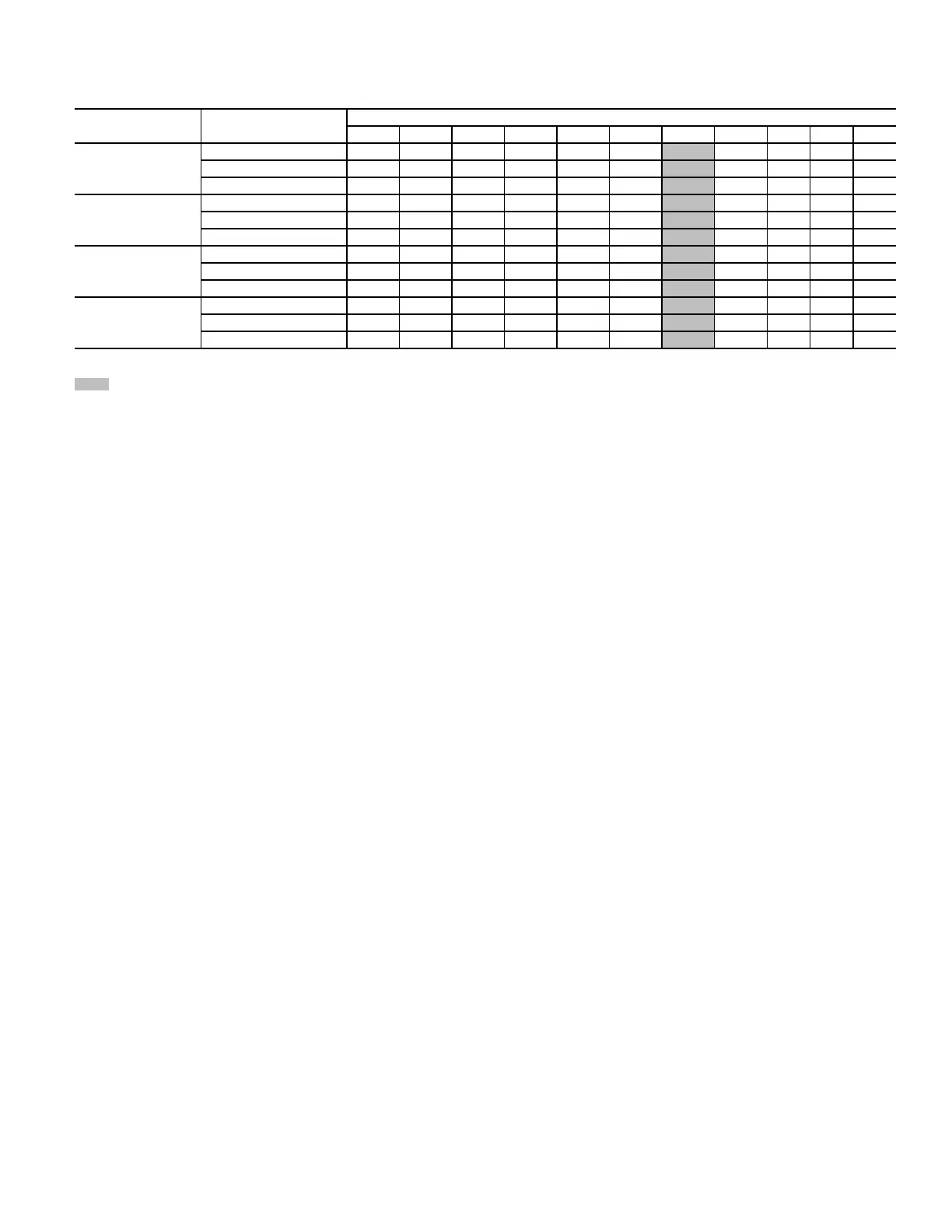

Table L — Pulley Adjustment (Horizontal) - Fan RPM at Motor Pulley Settings

MODEL SIZE

MOTOR/DRIVE

COMBO

MOTOR PULLEY TURNS OPEN

0 0.5 1.0 1.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0

17

3-phase

Standard Static 680 663 647 630 614 597

580 564 547 531 514

Medium Static 780 763 747 730 714 697

680 664 647 631 614

High Static 912 895 879 862 846 829

812 796 779 763 746

20

3-phase

Standard Static 822 802 782 762 742 722

702 682 662 642 622

Medium Static 879 862 846 829 813 796

779 763 746 730 713

High Static 1021 1002 984 965 947 928

909 891 872 854 835

24

3-phase

Standard Static 863 846 828 811 794 777

759 742 725 707 690

Medium Static 1021 1002 984 965 947 928

909 891 872 854 835

High Static 1176 1153 1129 1106 1082 1059

1035 1012 988 965 941

28

3-phase

Standard Static 791 777 762 748 733 719

705 690 676 661 647

Medium Static 923 906 889 873 856 839

822 805 789 772 755

High Static 1107 1087 1067 1047 1027 1007

986 966 946 926 906

Factory settings

APPENDIX C — FAN PERFORMANCE

Loading...

Loading...