BÜCHI Labortechnik AG

www.buchi.com

2

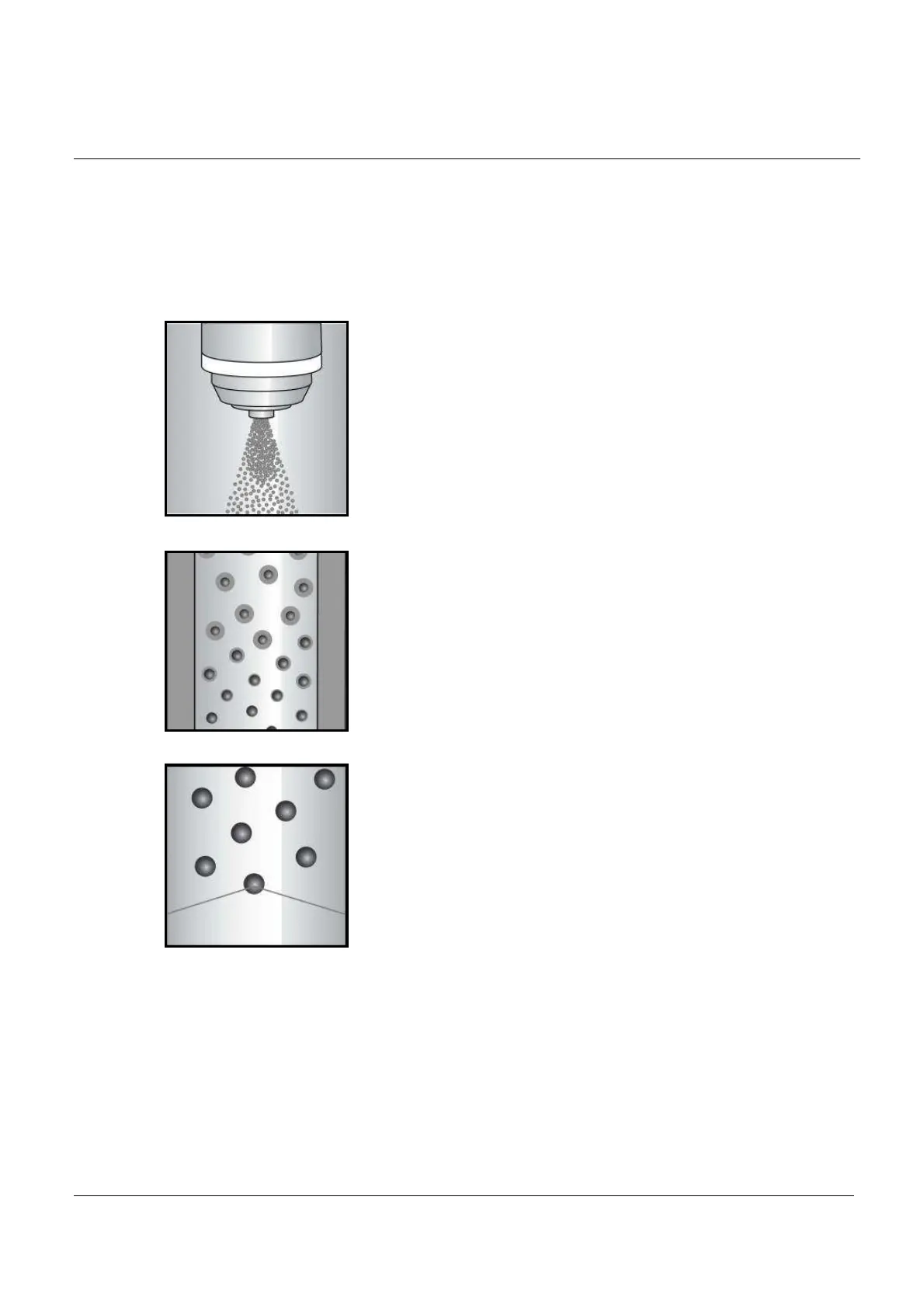

1.2 PRINCIPLE OF OPERATION

The unique detection principle of evaporative light scattering

detection involves a three-step process: nebulization of the

column effluent to form an aerosol, solvent evaporation within

a heated drift tube, and detection of the non-volatile solute

particles in the light scattering cell.

NEBULIZATION

EVAPORATION

DETECTION

NEBULIZATION

The column effluent from an HPLC separation enters the

nebulizer, where it is mixed with a steady stream of

nebulizing gas (usually nitrogen) to form an aerosol. The

aerosol consists of a uniform distribution of droplets whose

size is dependent on the gas flow rate used for the analysis.

The lower the gas flow rate used, the larger the resulting

droplets will be. Larger droplets scatter more light and

increase the sensitivity of the analysis, but they are also more

difficult to evaporate in the drift tube. There will be an

optimum gas flow rate for each method which will produce the

highest signal-to-noise ratio.

Lower mobile phase flow rates will require lower gas flow

rates for optimal nebulization. Substitution of a 2.1mm i.d.

column for your standard 4.6mm i.d. column will allow you to

greatly reduce the mobile phase flow rate while also

increasing the sensitivity of the analysis.

EVAPORATION

Evaporation of the volatile components in the aerosol occurs

in a heated, stainless steel drift tube. The optimum drift tube

temperature setting for an application will depend on mobile

phase composition, mobile phase flow rate, and on sample

volatility. Highly organic mobile phases require lower drift

tube temperatures for evaporation than highly aqueous

mobile phases. Lower mobile phase flow rates require lower

drift tube temperatures than higher mobile phase flow rates.

Semi-volatile analytes require the use of much lower drift

tube temperatures to obtain optimum sensitivity. The

optimum temperature should be determined by observing

the signal-to-noise ratio with respect to temperature.

Within the Model 3300 ELSD drift tube, a PTFE-coated,

stainless steel impactor plate is located three inches from

the nebulizer. The plate is perpendicular to the aerosol path

so as the aerosol contacts the plate, larger droplets exit

through the drain tube on the side panel. The remaining

droplets pass around the impactor and travel through the

drift tube to the optical cell for detection. The removal of the

larger droplets allows operation of the Model 3300 ELSD at

low temperatures, making it ideal for the analysis of semi-

volatile compounds.

Non-volatile impurities in the mobile phase or nebulizing gas

will produce noise. Using the highest quality gas, solvents,

and volatile buffers (preferably filtered) will greatly reduce

baseline noise. Noise will also increase if the mobile phase

has not been completely evaporated. Detector settings must

be carefully selected to ensure adequate mobile phase

evaporation.

DETECTION

The non-volatile sample particles emerge from the drift tube

in the mobile phase vapor and enter the light scattering cell.

In the optical cell, sample particles scatter light emitted by a

laser light source. The scattered light is detected by a silicon

photodiode, generating a signal proportional to sample

mass. This signal is sent to the analog output for data

collection. The advanced design of the Model 3300 ELSD

optical components

1

provides excellent sensitivity for HPLC

a

nalysis.

1

US Patent #6229605; other patents pending

Loading...

Loading...