Do you have a question about the Buchi NIRMaster and is the answer not in the manual?

Defines the required training and experience for operating the instrument safely.

Details the intended applications and tasks for the NIRMaster system.

Lists prohibited uses and potential consequences of misuse for safety and property.

Lists general safety messages and counter-measures for handling the instrument.

Details warning stickers found on the housing and assemblies of the NIRMaster.

Discusses the necessity of PPE for compliance with industrial safety standards.

Lists the safety elements integrated into the instrument for enhanced protection.

Defines responsibilities for personnel training, incident reporting, and legal compliance.

Outlines the operator's responsibility for instrument condition and authorized maintenance.

Specifies the use of genuine consumables and authorized spare parts for maintenance.

States that modifications require prior consultation and written approval from the manufacturer.

Explains the details found on the instrument's type plate (e.g., manufacturer, type, serial number).

Provides specifications for voltage, frequency, power consumption, IP class, and fuses.

Details operating requirements for pollution degree, temperature, altitude, and humidity.

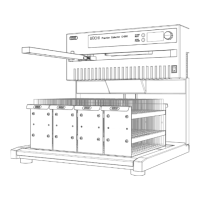

Lists the physical dimensions (height, width, depth) and weight of the NIRMaster models.

Specifies interferometer type, spectral range, resolution, accuracy, and SNR.

Lists compatible peripherals like drives, monitors, and input devices.

Details the specifications of the embedded PC, including CPU, RAM, and OS.

Lists the materials used for various components of the NIRMaster instrument.

Lists product names and trademarks associated with the NIRMaster and its components.

Explains the FT-NIR spectrometer principle and how interferograms are generated.

Details the analysis of non-translucent materials using diffuse reflection.

Describes the analysis of translucent and opaque liquids using transflectance.

Describes the embedded PC running Windows, hosting the NIRWare software.

Explains how environmental conditions relate to the system's IP class after installation.

Specifies indoor installation, clearance, environmental sources, and stability requirements.

Describes the steps to power on the instrument and initiate the bootup process.

Explains the necessary warm-up time for the spectrometer to reach optimal performance.

Recommends running internal tests to monitor and verify system performance.

Details how temperature sensors monitor internal instrument temperatures against predefined limits.

Tests the linearity of the spectrometer's intensity scale using gray filters.

Determines the ratio of signal power to noise power using high and low flux beams.

Checks the wavenumber stability of the system using a PMMA reference plate.

Compensates for environmental effects and ensures measurement stability.

Guides the user through the process of taking an external reference measurement.

Mandatory conditions for performing an additional external reference measurement.

Describes the two available user interfaces for the Operator software.

Describes the touch-screen optimized interface for production environments.

Details the mouse/keyboard optimized interface with extended functionality.

Explains how to start the NIRMaster Operator software manually or automatically.

Details the function of common buttons used within the Operator software wizard.

Describes the login procedure using user name and password for accessing the software.

Guides the operator through the measurement process step-by-step.

Guides the user to select the appropriate application for the measurement.

Explains how to select an existing batch or create a new one for sample production.

Details placing the sample and initiating the measurement process.

Describes how measurement results are displayed and interpreted based on calibration ranges.

Explains how invalid results are indicated and how to view detailed results.

Details how to start new measurements, rerun existing ones, or finalize a batch.

Provides instructions for safely powering off the instrument.

Provides steps for safely powering off the NIRMaster through the standard procedure.

Explains when and how to perform a forced shutdown, with warnings about data integrity.

Outlines the recommended maintenance tasks, intervals, and responsibilities.

Provides instructions for cleaning the instrument and its components to prevent contamination.

Details how to clean the instrument's housing, including recommendations for disinfectants.

Explains how to clean the external reference and transflectance adapter for dependable measurements.

Provides instructions for cleaning the spinner, including dishwasher compatibility and O-ring maintenance.

Details cleaning methods for various accessories and sample vessels, including dishwasher and disinfectant use.

Recommends frequent backups and outlines backup strategies and options.

Explains the Grandfather-Father-Son media rotation schedule for backups.

Lists methods for backing up data via USB or network storage.

Refers to the BUCHI Database Manager manual for detailed backup file creation.

Describes creating new databases and importing calibrations via Archive Operations.

Provides step-by-step instructions for backing up data to a USB storage device.

Explains the preferred method of backing up data to a local network drive.

Explains how to access and reset the instrument's internal fuses.

Details the process for replacing the primary lamp module and the function of the secondary backup lamp.

Guides on resetting the software hour counter after lamp replacement for accurate lifetime monitoring.

Explains how to change the password for software access and security.

Lists common malfunctions, their possible causes, and suggested corrective actions for operators.

Introduces the NADIA tool for performing advanced diagnostic tests on the NIRMaster.

Discusses reasons for reference measurement failure and provides solutions, including rerunning or storing new data.

Details the configuration of the two Ethernet LAN sockets for network connectivity.

Provides instructions and safety precautions for storing and transporting the instrument.

Explains the function of the mechanical transportation lock and how to engage/disengage it.

Details the steps to access and operate the locking mechanism for the interferometer.

Advises on environmentally friendly disposal methods and compliance with local laws.

Lists the standard components included with the NIRMaster and NIRMaster Pro models.

Provides a detailed list of spare parts, accessories, and consumables with their order numbers.

Details FCC compliance information for Class A digital devices and potential interference.

Presents the declaration of conformity to relevant European directives and international standards.

| Technology | Near Infrared Spectroscopy (NIRS) |

|---|---|

| Wavelength Range | 1000 - 2500 nm |

| Detector | InGaAs (Indium Gallium Arsenide) |

| Light Source | Tungsten Halogen Lamp |

| Sample Presentation | Reflectance and Transmittance |

| Software | NIRWare |