22

Installation and maintenance instructions Logano G334 X gas-fired boiler • Issue 09/2005

We reserve the right to make any changes due to technical modifications.

Boiler installation7

7.8 Filling heating system and checking for leaks

The boiler is tested for leaks at the factory. Before

placing the heating system tank into use, check it for

soundness to avoid leaks occurring during operation.

Water treatment

Carry out the leak test at 1.5 times the normal operating

pressure and as specified by the local codes as follows:

z Close valve at supply connection (Î page 15).

z Close open connections with blank plugs.

z Disconnect the expansion tank from the system by

closing the cap valve.

z Open mixing and stop valves on hot water side.

z Fill boiler slowly with water from the building

connection.

z Turn cap of automatic vent one revolution to allow the

air to escape.

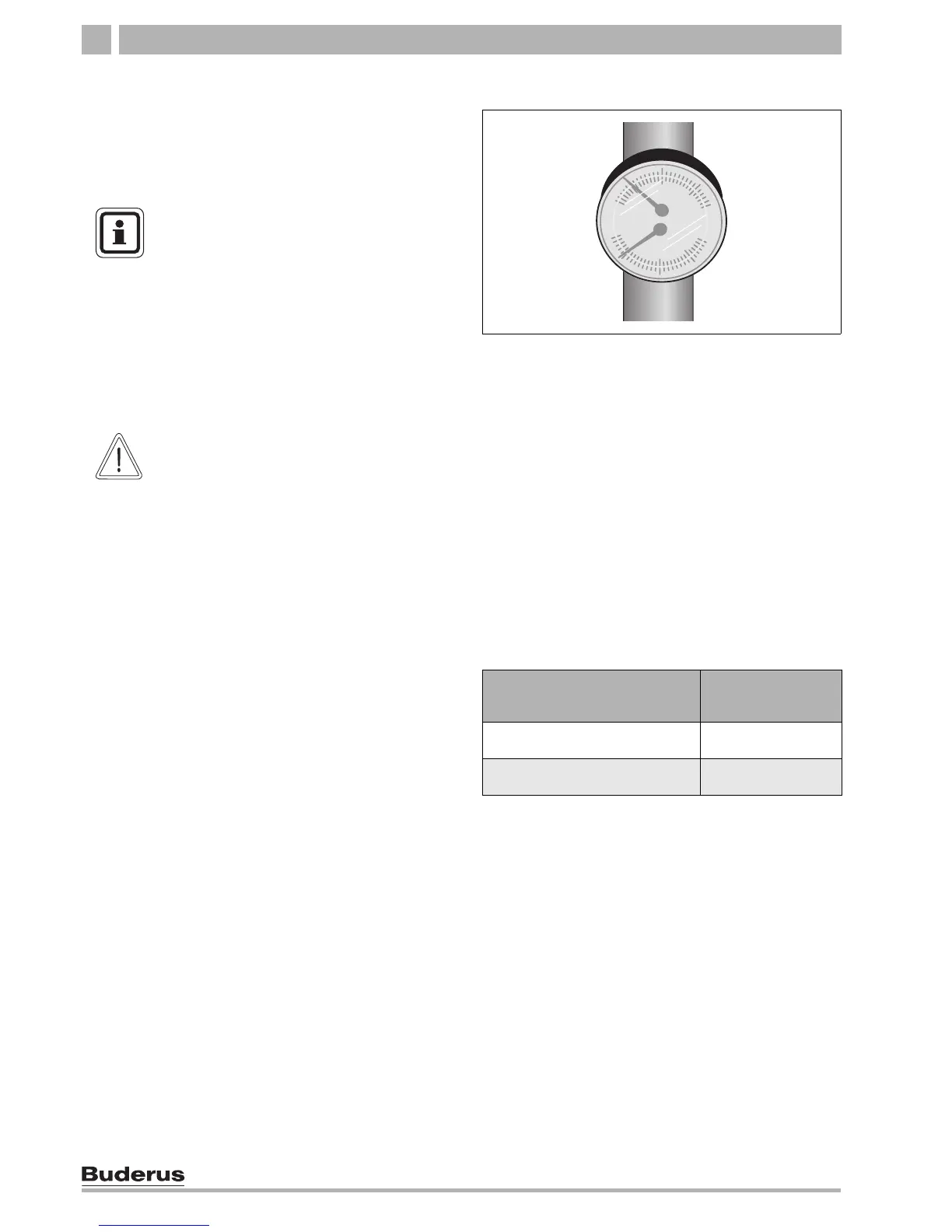

z Slowly fill heating system. Observe pressure display

on pressure gauge during this process.

z Check connections and pipes for leaks.

z Bleed heating system through the bleed valves on

the radiators.

z If the pressure falls while bleeding, water must be

added.

z Install relief valve.

Fig. 19 Temperature/pressure gauge (owner installation)

USER NOTE

z Have the water analyzed before filling

the heating system.

z Compare the results of this analysis

with the Î

technical documentation

on water quality for boiler water.

z Please consult the local water supply

company if there are major

differences, such as extremely hard

water or a pH level below 7.0.

CAUTION!

SYSTEM DAMAGE

due to overpressure during the leak test.

Pressure, control or safety components

may be damaged by high pressure.

z Before conducting the leak test make

sure that no pressure, control or safety

components that cannot be

disconnected from the water

compartment of the boiler are installed.

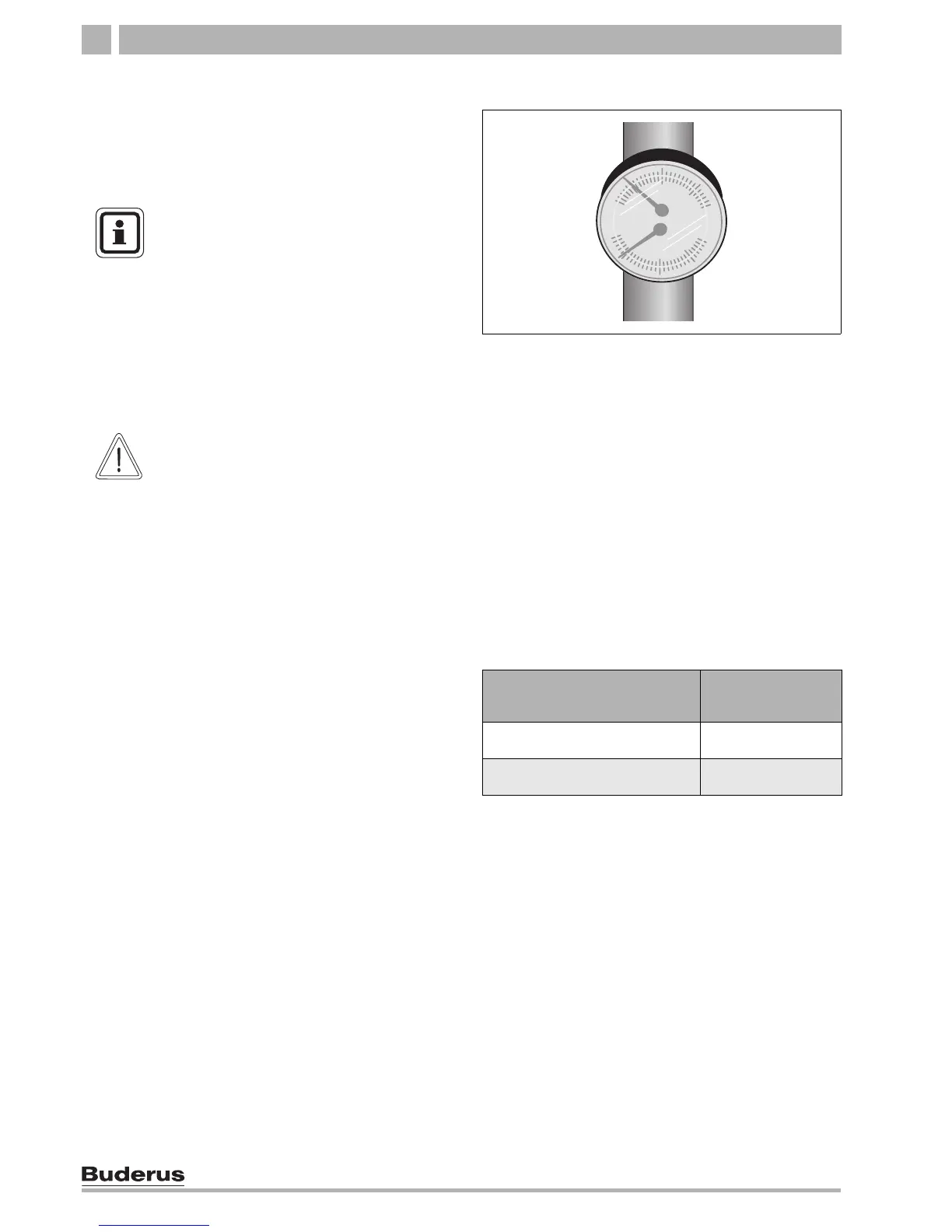

Maximum

operating pressure

Maximum

construction site test

pressure

30 psi (with the included relief

valve)

45 psi

58 psi (with a different relief

valve)

75 psi

Tab. 6 Test pressures

Loading...

Loading...