11

6.2.1 Cleaning the nozzle

• Wipethenozzlewithaclothtoremoveslightexternaldirt.

• Toremoveblockagesinsertadrillbit,needleorwireofsuitablediameterintothe

nozzleorice.

Instubborncasesreplacethenozzle(seeSection6.3).

6.3 Nozzle systems

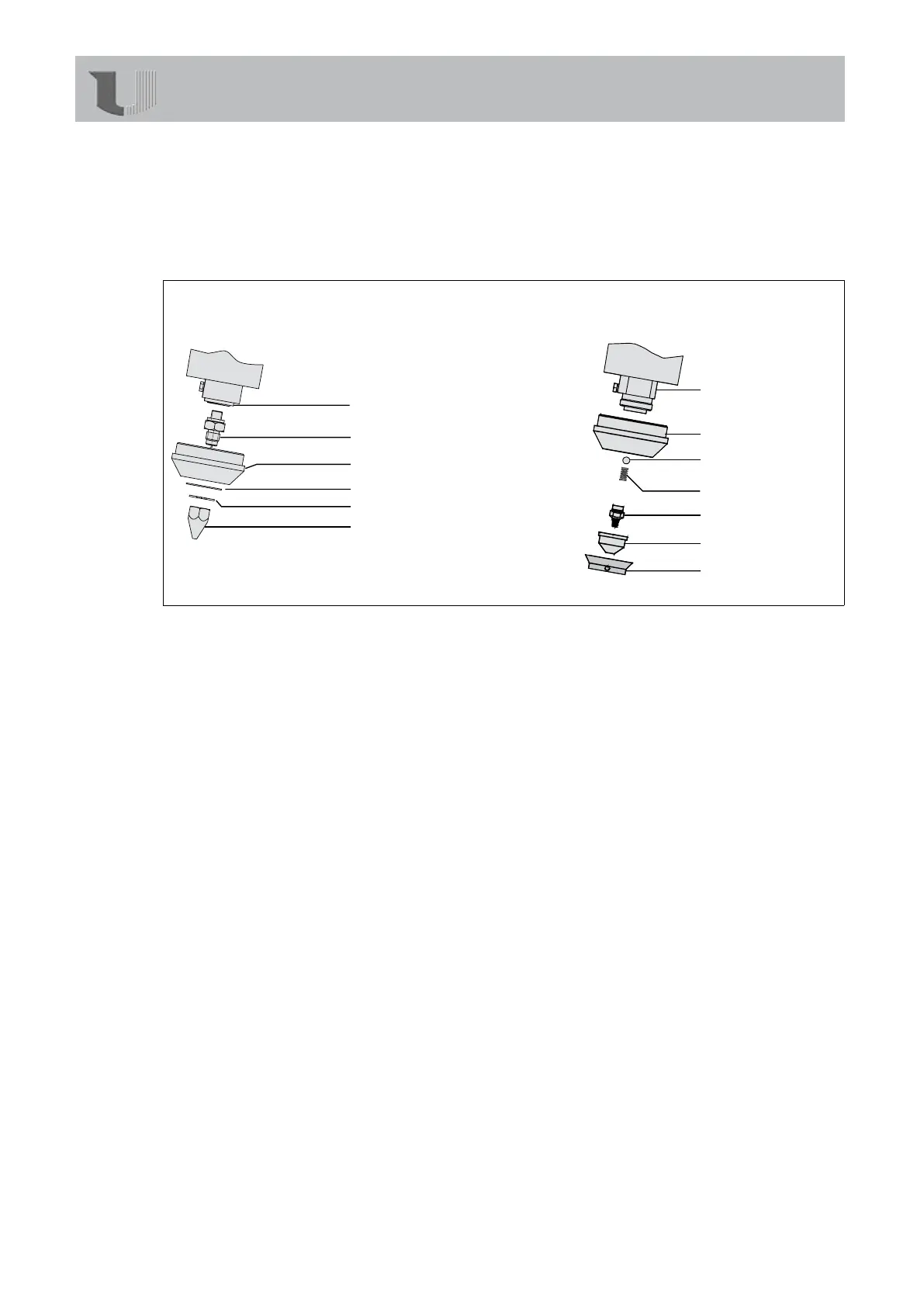

Valve seat (A6)

Nozzle foot (A5)

Protection cap (A4)

Washer (A3)

Locking ring (A2)

Cone nozzle (A1)

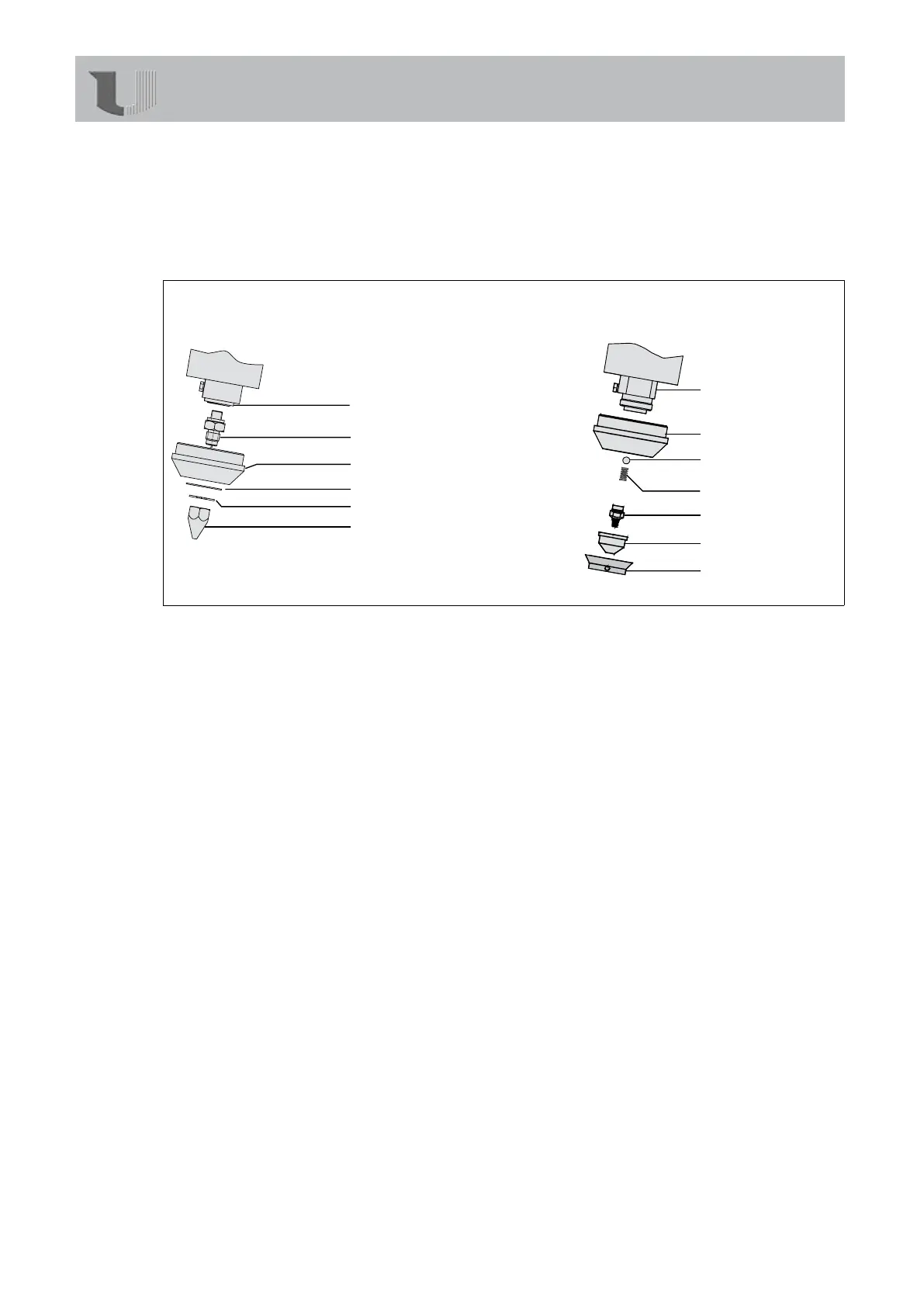

Nozzle block (B7)

Protection cap (B6)

Ball (B5)

Pressure spring (B4)

Swirl nozzle (B3)

Air cap (B2)

Cap ring (B1)

Fig 6.3/1: Nozzle systems in detail

6.3.1 Replacing the cone nozzle (HB 710)

Tools needed • 2open-endspannerssize19

• 1Seegercirclipringpliers

1. Disconnectthecompressedairsupply.

2. Letthedeviceheatupthoroughly.

3. Securethenozzlefoot(A5)andunscrewtheconenozzle(A1).

4. Screwonthenewconenozzle(A1)byhandrstandallowtoheatupfor2minutes.

5. Re-securethenozzlefoot(A5).Tightenthenewconenozzle(A1)withoutusingforce.

6. Assembletheremainingpartsinreverseorder.

6.3.2 Replacing the nozzle end (HB 710)

Tools needed • 2open-endspannerssize19

• 1open-endspannersize36orpipewrench

• 1Seegercirclipringpliers

Theremustbenomeltatallinthetankwhenthenozzleendisreplaced.

Thereforedischargethemeltcompletely,e.g.intoacollectingvessel.

1. First,proceedasdescribedinchapter6.3.1uptoPoint3(dismantlingthenozzle).

2. Removethelockingring(A2).

3. Removethewasher(A3)andtheprotectioncap(A4).

4. Securethevalveseat(A6)withtheopen-endspannersize36orthepipewrench.

Unscrewthenozzlefoot(A5).

5. Screwonthenewnozzlefoothandtight.Nowtightenlightly(withoutusingforce)with

theopen-endspanner.

6. Assembletheremainingpartsinreverseorder.

Servicing/maintenance

Loading...

Loading...