2

1 General

PleasereadthisOperatingManualthroughcarefullyandcompletelybeforerstusingthe

Applicator.PayparticularattentiontothesafetyinstructionsinSection2.

ThisOperatingManualmustalwaysbewithineasyreachforanyuser.

1.1 Scope of use

TheHB710/HB710SprayApplicatorisforthemeltingandmetereddischargeofmelts

(thermoplasticsubstancessuchashot-meltadhesives,waxes,etc.)asabead(HB710)

orspray-oncoating(HB710Spray)usinginterchangeableapplicationtools(useasin-

tended).

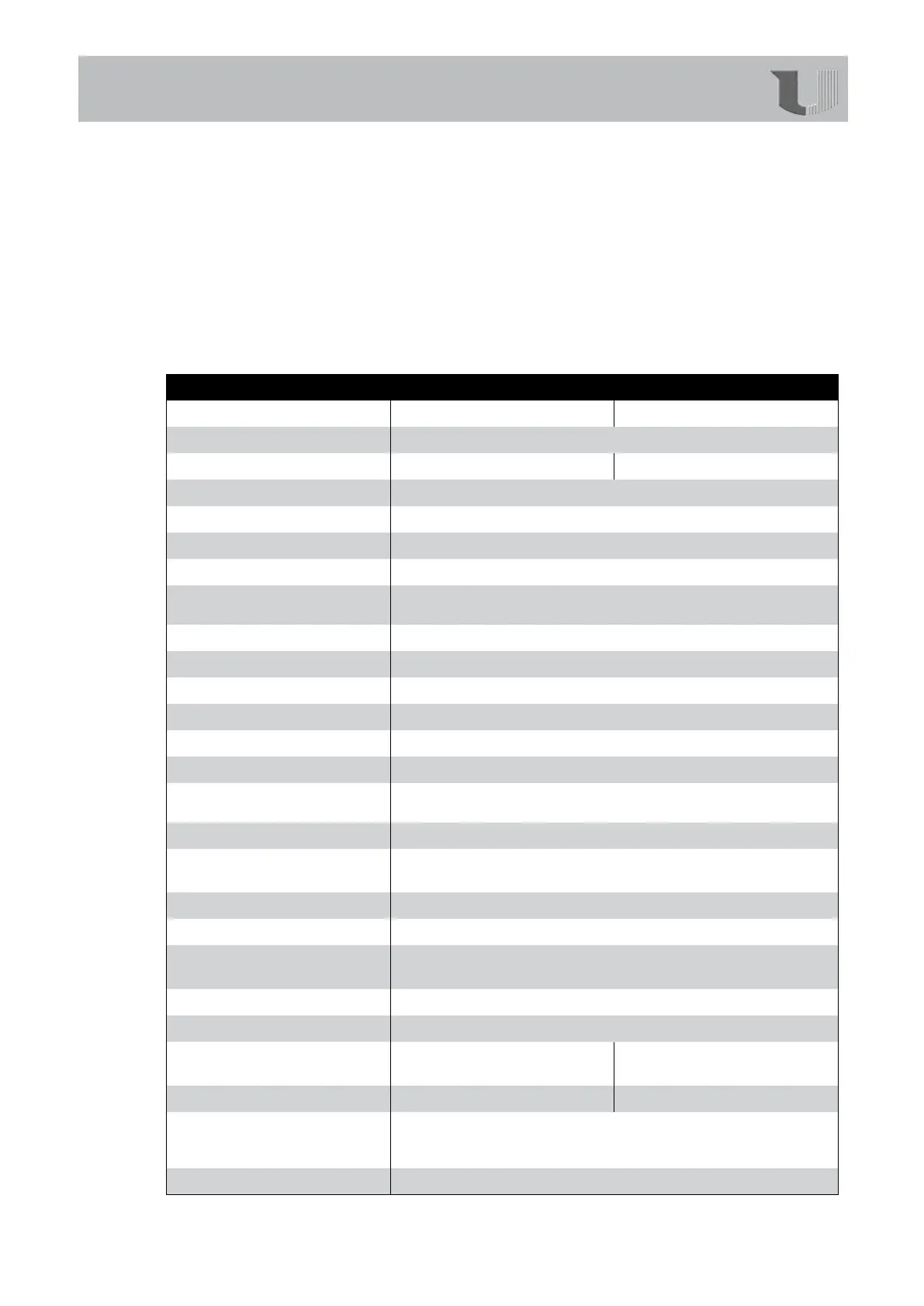

1.2 Technical data

Model HB 710 HB 710 Spray

PartNo. H218600 H218700

Kitincludes Applicator,toolset,workingbracket/workstation(optional)

Weight approx3lbs/1.35g approx3.3lbs/1.50kg

Powerconnection 120VAC/60Hz/earthing-pinplug

Powerrequirement[W] 600

Powerconsumption[A] 2.6

Protection(asperDINIEC34T5) IP30

Safetyclass

(asperDINVDE0720)

I(safetyearthterminal)

Temperaturecontrol electronic

Temperaturelimitation thermalcut-out(500°F±19.8°F/260°C±11°C)

Operatingtemperature 104°F…410°F/40°C…210°C

Temperatureconstancy ±3.6°F/±2.0°C

Factorypresetting 356°F/180°C

Temperatureindication digitalviaLEDdisplay

Automatictemperaturereduction

(ACE)

Factorypresettoreducetemperatureby104°F/40°C

after30minnon-use

Warm-uptime[min] ~3.0…4.0

Hot-meltingcapacity(dependent

onmelt)

withplugs:7.05lbs/h/3.20kg/h

withgranulate:2.87lbs/h/1.30kg/h

Capacityofmeltreservoir 7.76oz/200ml

Conveyorsystem compressedair

Compressed-airconnection max.145psi/10bar(serviceunitwithquick-actioncoupling)

Thecompressedairmustbecondensate-andacid-free

Operatingpressure 21.8…87.0psi/1.5…6.0bar

Protectionagainstoverpressure limitedbyreducingvalveto87psi/6bar

Airconsumption(at72.5psi/

5baroperatingpressure)

33.8oz/1lper

triggeractuation max.33.8oz/s/1l/s

Nozzles(standard) conenozzleØ1.5mm swirlsprayheadØ1.5mm

Lengthofsupplylinewith

electricalandpneumaticconnec-

tions

9.84ft/3.0m

Recommendedmeltingstock BÜHNENhot-meltadhesivesinplugorgranularform

General

Loading...

Loading...