23

Installation

CAUTION!

Risk of injury due heavy devices!

▶ Duringtransportorduringassembly,aheavydevicemayfall

andcauseinjury.

▶ Donottransport,installorremoveheavydeviceswithoutthe

aidofasecondpersonandusingsuitableauxiliaryequipment.

▶ Useappropriatetools.

8.2 Before installation

• Theangle-seatcontrolvalvecanbeinstalledinanyinstallation

position,preferablywiththeactuatorinuprightposition.

• Beforeconnectingthevalve,ensurethepipelinesareush.

• Makecertaintheowdirectioniscorrect(Flowdirection

alwaysbelowseat).

8.2.1 Preparatory work

→ Cleanpipelines(Sealingmaterial,swarf,etc.).

Devices with welded body

NOTE!

For valves with installed control:

Whenweldingthevalvebodyintothepipeline,thecontrol

mustnotbeinstalled.

▶ Removecontrolfromtheactuatordescribedbelow.

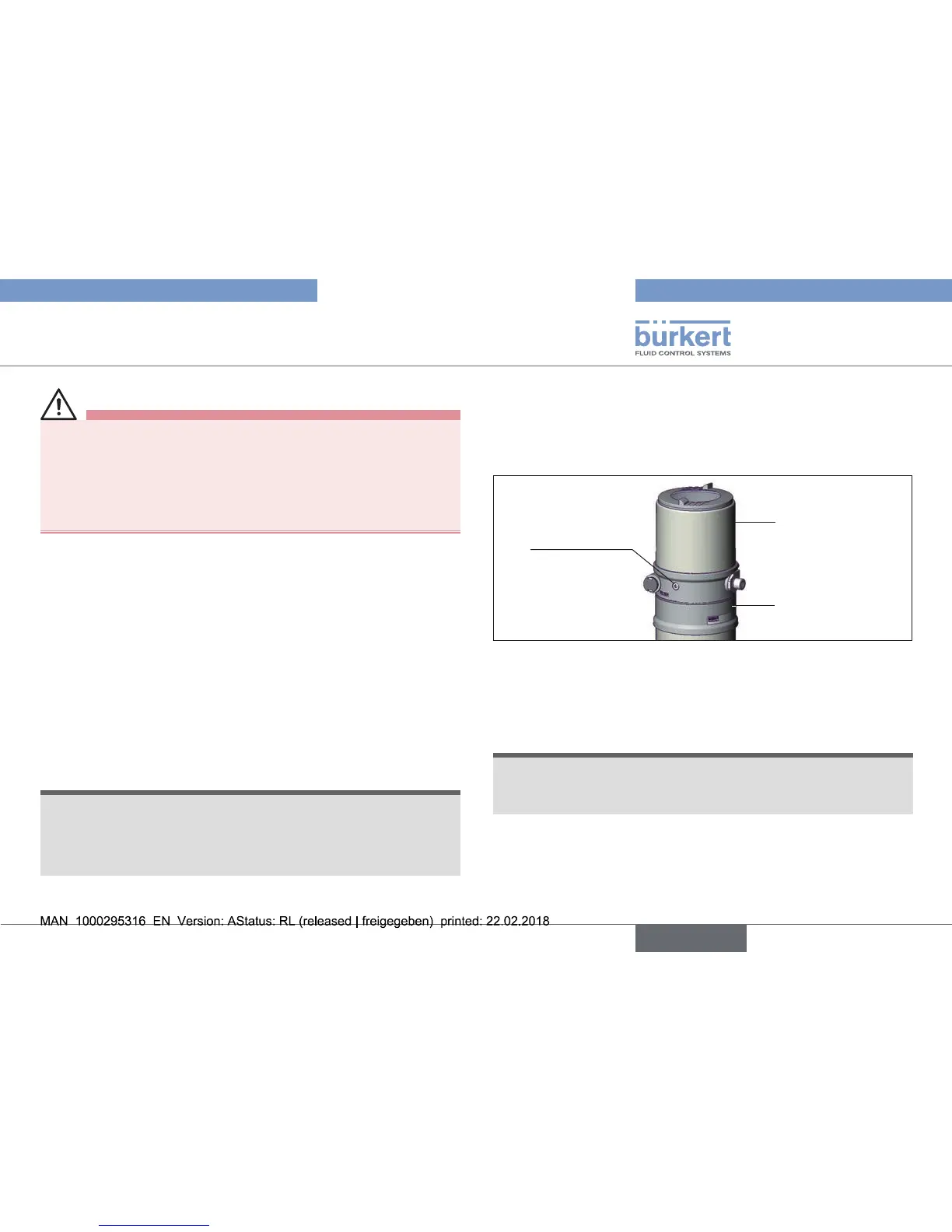

Removethecontrolunitfromtheactuator(ifpresent):

→ Clampthevalvebodyinaholdingdevice.

→ Loosenthefasteningscrews(2x).

→ Removethecontrolunitupwards.

Fasteningscrew

(2x)

Controlunit

Actuator

Fig. 16: Disassembly the control unit

Removetheactuatorfromthevalvebody.

→ Installcollet(whitegrommet)inpilotairport1.

NOTE!

Damage to the seat seal or the seat contour!

▶ Whenremovingtheactuator,ensurethatthevalveisinopen

position.

→ ControlfunctionApressurizethepilotairport1withcom-

pressedair(5bar):valveopens.

→ Usingasuitableopen-endwrench,placethewrenchaton

thepipe.

Loading...

Loading...