28

Installation

8.4 Pneumatic connection

DANGER!

Danger – high pressure in the equipment!

▶ Beforelooseningthelinesandvalves,turnothepressure

andventthelines.

WARNING!

Risk of injury from unsuitable connection hoses!

Hoseswhichcannotwithstandthepressureandtemperature

rangemayresultinhazardoussituations.

▶ Useonlyhoseswhichareauthorizedfortheindicatedpres-

sureandtemperaturerange.

▶ Observethedatasheetspecicationsfromthehose

manufacturers.

For control function I – Danger if pilot pressure fails!

ForcontrolfunctionIcontrolandresettingoccurpneumati-

cally.

Ifthepressurefails,nodenedpositionisreached.

▶ Toensureacontrolledrestart,rstpressurizethedevicewith

pilotpressure,thenswitchonthemedium.

Thepneumaticconnectionoftheangle-seatcontrol

valvecanbecarriedoutonlyinconnectionwiththe

appropriatecontrolunit.

Possiblecontrolunitsare:

PositionerType8692,8694and8696

ProcesscontrollerType8693

8.4.1 Connection of the control medium

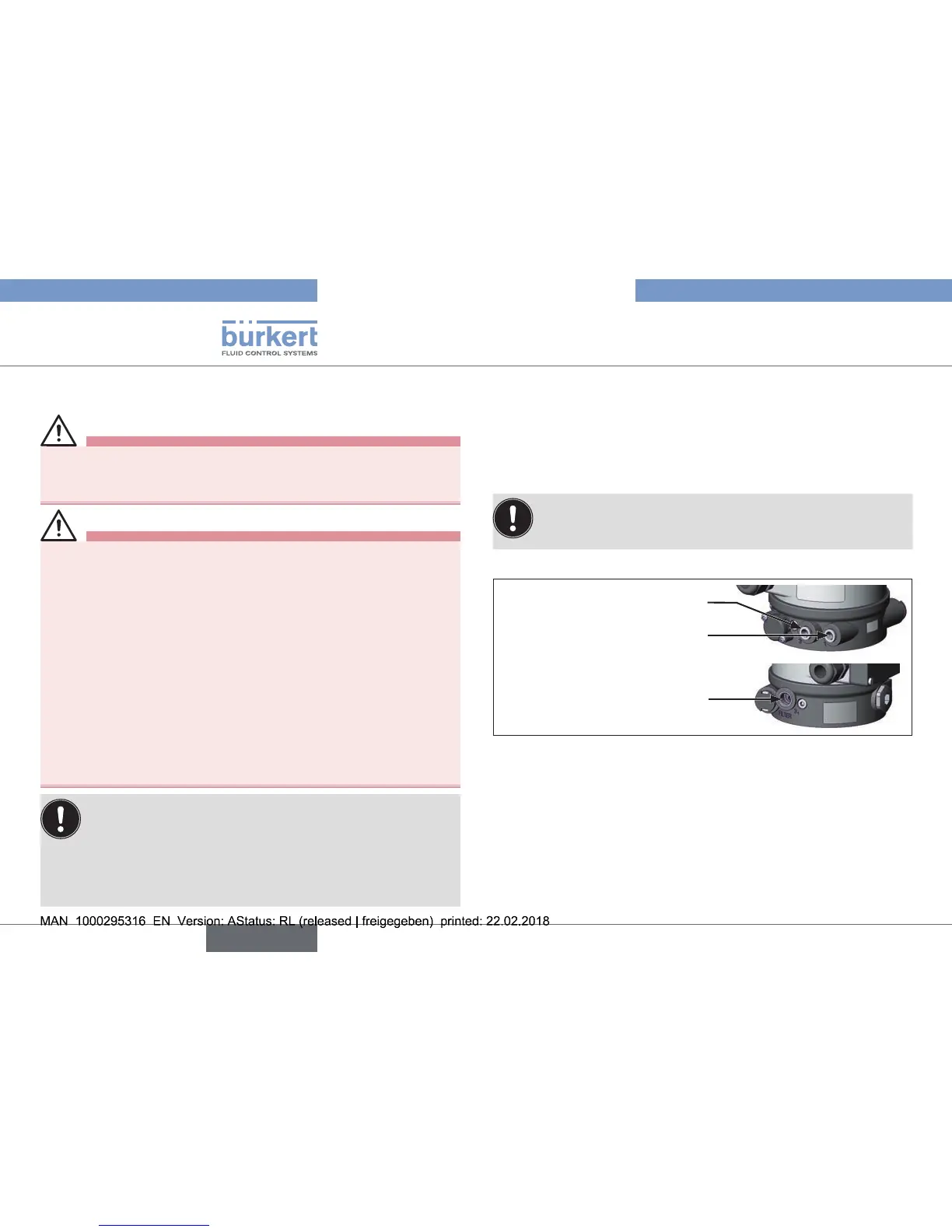

→ Connectthecontrolmediumtothepilotairport(1)

(3–7bar;instrumentair,freeofoil,wateranddust).

→ Fittheexhaustlineorasilencertotheexhaustairport(3)

and,ifavailable,totheexhaustairport(3.1).

Ifusedinanaggressiveenvironment,werecommend

conveyingallfreepneumaticconnectionsintoaneutral

atmospherewiththeaidofapneumatichose.

Pilotairport

Exhaustairport

Additionalexhaustairportonly

withpilot-operatedcontrol

systemforhighairoutput

(actuatorsizeø130)

1

3

3.1

Fig. 23: Pneumatic connection

Control air hose:

6/4mmor1/4"pilotairhosescanbeused.

ApilotairportviaG1/8threadisavailableasanoption.

Loading...

Loading...