27

Installation

8.3.4 Rotating the actuator

Thepositionoftheconnectionscanbealignedsteplesslyby

rotatingtheactuatorthrough360°.

Onlytheentireactuatorcanberotated.Thecontrolunit

cannotberotatedcontrarytotheactuator.

NOTE!

Damage to the seat seal or the seat contour!

▶ When rotating the actuator,ensurethat the valve is in open

position.

Procedure:

→ Clampthevalvebodyinaholdingdevice

(appliesonlytovalveswhichhavenotyetbeeninstalled).

→ Control function A:

Without unit control:pressurizethepilotairport1withcom-

pressedair(5bar):valveopens.

With unit control:openthevalveaccordingtotheoperating

instructionsforthecontrolunit.

→ Counterontheatsofthenipplewithasuitableopen-endwrench.

WARNING!

Risk of injury from discharge of medium and pressure!

Ifthedirectionofrotationiswrong,thebodyinterfacemay

becomedetached.

▶ Rotatetheactuatormoduleinthespecieddirectiononly(see

“Fig.22”)!

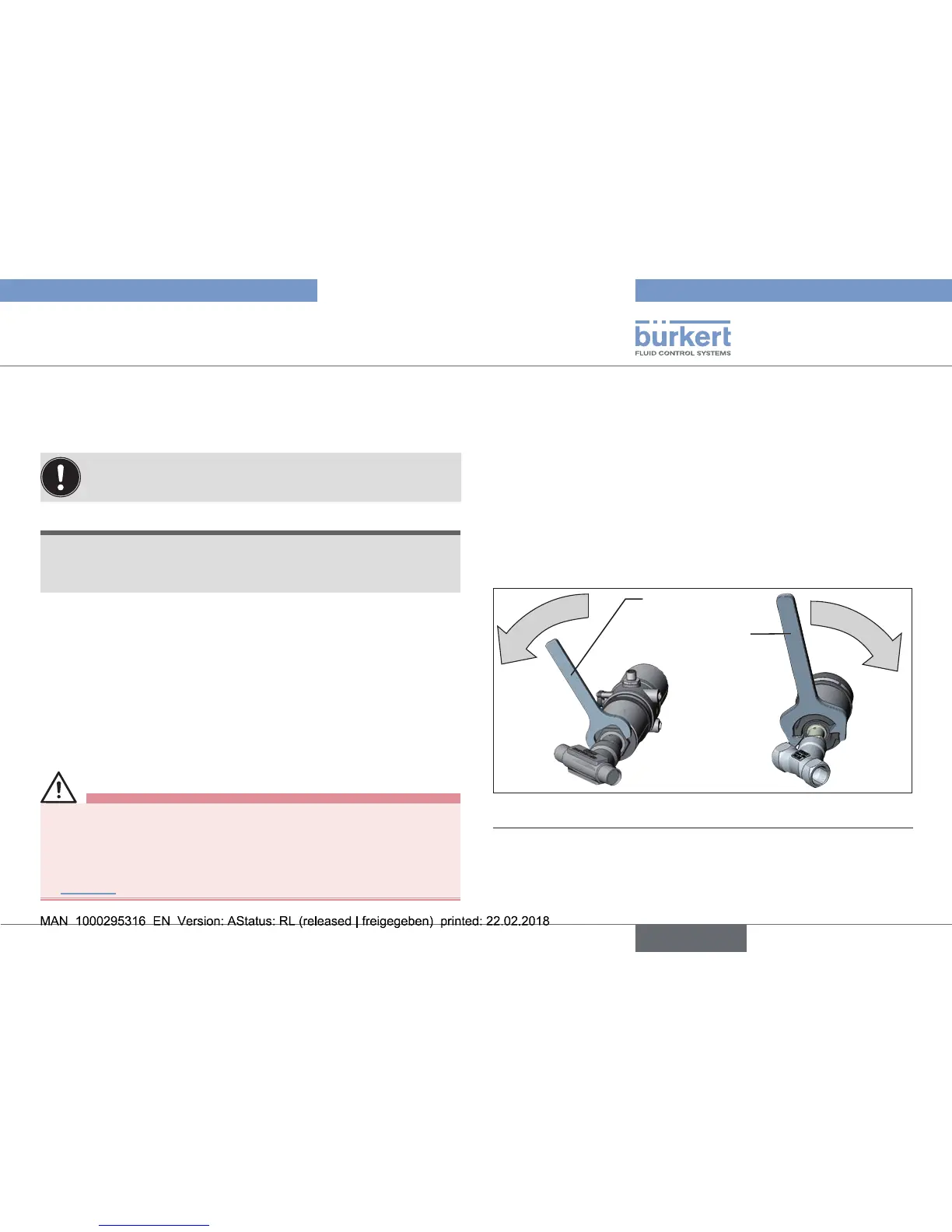

Actuatorwithhexagon:

→ Placesuitableopen-endwrenchonthehexagonofthe

actuator.

→ Rotatecounter-clockwise(asseenfrombelow)tobringthe

actuatorintotherequiredposition.

Actuatorwithouthexagon:

→ Fitspecialwrench

9)

exactlyintothewrenchcontouronthe

undersideoftheactuator.

→ Rotateclockwise(asseenfrombelow)tobringtheactuator

intotherequiredposition.

Open-endwrench

with

hexagon

10)

Specialwrench

without

hexagon

11)

Fig. 22: Rotating with special key / open-end wrench

9) The special key (identication number 00 665 702) is available

from your Bürkert sales oce.

10) Series production status since middle of 2011

11) Series production status up to middle of 2011.

Loading...

Loading...