32

Maintenance, cleaning

Removing the actuator from the valve body

→ Clampthevalvebodyinaholdingdevice

(appliesonlytovalveswhichhavenotyetbeeninstalled).

NOTE!

Damage to the seat seal or the seat contour!

▶ Whenremovingtheactuator,ensurethatthevalveisinopen

position.

→ Control function A:

Without unit control:

pressurizethepilotairport1withcom-

pressedair(5bar):valveopens.

With unit control:openthevalveaccordingtotheoperating

instructionsforthecontrolunit.

→ Usingasuitableopen-endwrench,placethewrenchaton

thepipe.

→ Unscrewtheactuatorfromthevalvebody.

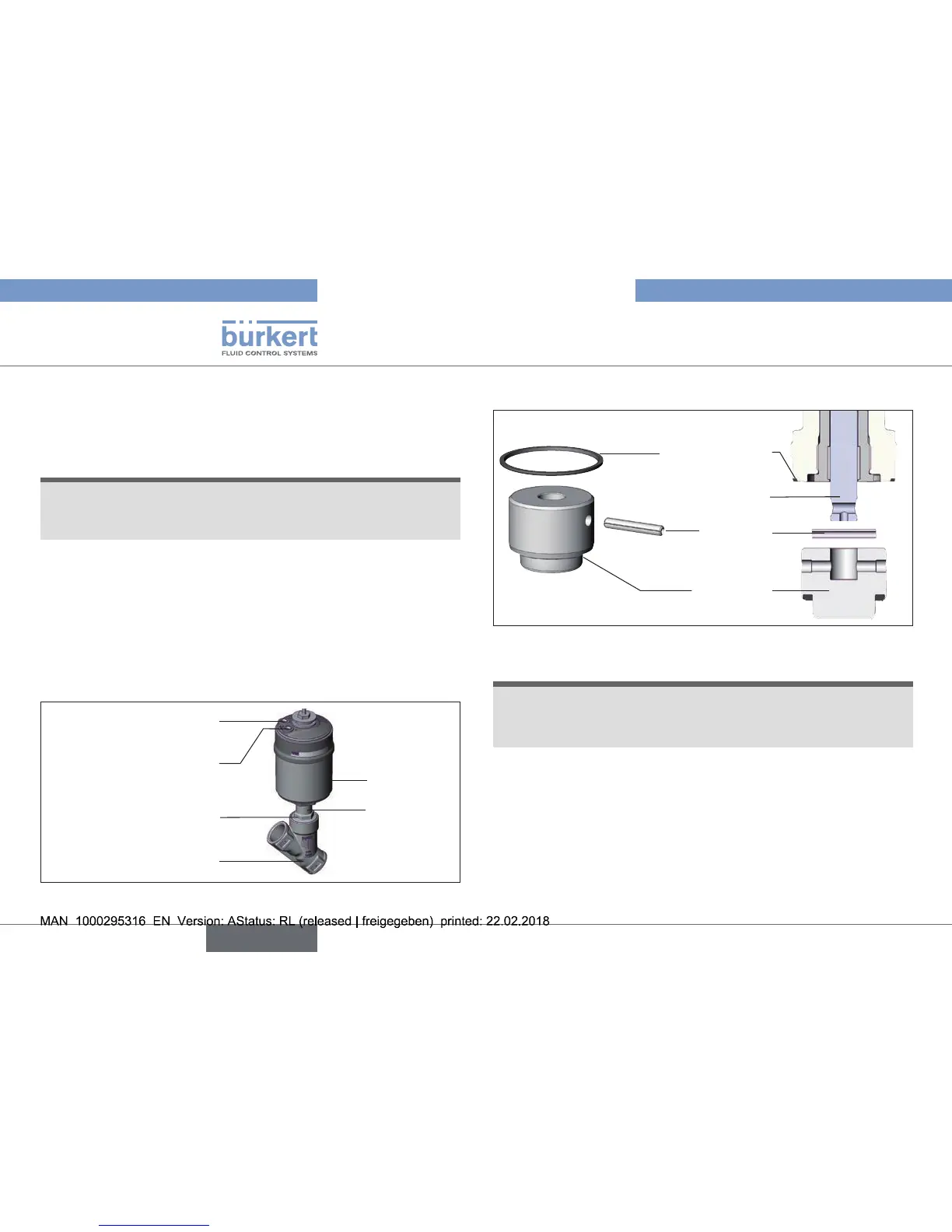

Actuator

Nipple

Valvebody

Flatsforopen-

endwrench

Pilotairport

Exhaustairport

2

1

Fig. 25: Valve

Replace the control cone set

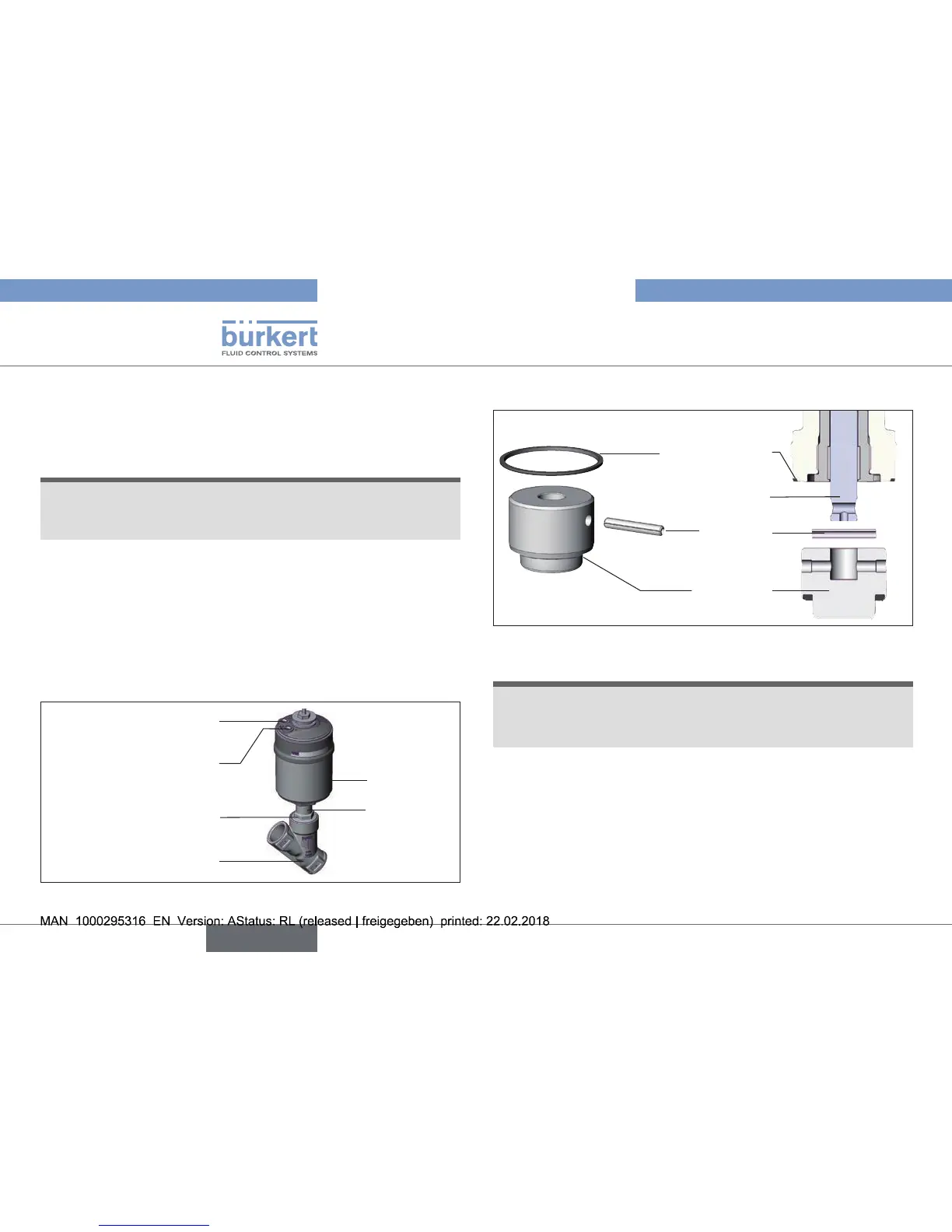

Spindle

Dowelpin

Controlcone

Seal

Fig. 26: Replacing the control cone set

NOTE!

Important information for the problem-free and safe functioning

of the device!

Thesealingfaceofthecontrolconemustnotbedamaged.

Procedure:

→ Knockoutdowelpinwithasuitablepinpunch.

Pin punch ø 4 mm,forspindlediameter10mm

Pin punch ø 5 mm,forspindlediameter14mm

→ Removecontrolcone.

→ Attachnewcontrolconetothespindle.

→ Alignboresofthecontrolconeandspindle.

Loading...

Loading...