24

Installation

8.3 Installation

WARNING!

Risk of injury due to improper operation.

Failuretoobservethetighteningtorquevalueisdangerousdue

totheriskofdamagetothedevice.

▶ Useanopen-endwrenchforinstallation,neverapipe

wrench.

▶ Observetighteningtorque(see“Tab.11”).

Dirt trap for devices with approval according to EN161

AccordingtoEN161"Automaticshut-ovalvesforgasburners

andgasappliances",adirttrap,whichpreventsthepenetration

ofa1mmtestpin,mustbeinstalledupstreamofthevalve.

8.3.1 Installing the body

Welded connection

→ Weldorbondvalvebodyinpipelinesystem.

Other body variants

→ Connect valve body to pipeline.

8.3.2 Installing the actuator (welded

connection)

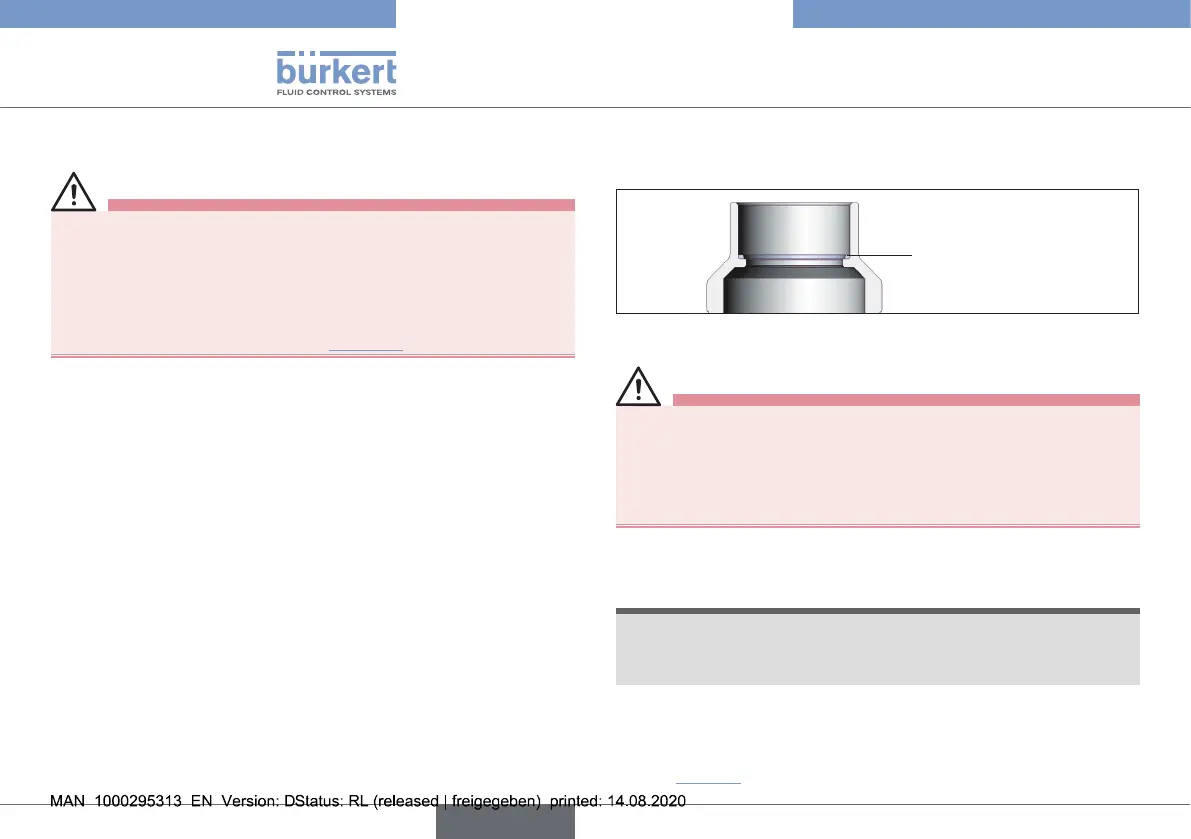

Seal

Fig. 11: Seal

→ Checksealandreplaceifrequired.

WARNING!

Risk due to incorrect lubricants.

Unsuitablelubricantmaycontaminatethemedium.Thereisa

riskofexplosioninoxygenapplications.

▶ Forspecicapplications,e.g.oxygenoranalysisapplica-

tions,useapprovedlubricantsonly.

→ Beforere-installation,greasenipplethreadoftheactuator

(e.g.usingKlüberpasteUH196-402fromKlüber).

NOTE!

Damage to the valve seat seal or seat contour.

▶ Wheninstallingtheactuator,thevalvemustbeintheopen

position.

→ ForcontrolfunctionApressurisethepilotairport1withcom-

pressedair(5bar):Valveopens.

→ Screwactuatorintothevalvebody.Observetighteningtorque

(see“Tab.1”).

Type2301

English

Loading...

Loading...