27

Installation

WARNING!

Risk of injury from discharge of pressure and escaping

medium.

Thebodyconnectioncanloosenwhenrotatedincorrectly.

▶ Onlyturntheactuatorin the specied direction(see“Fig.

15”)!

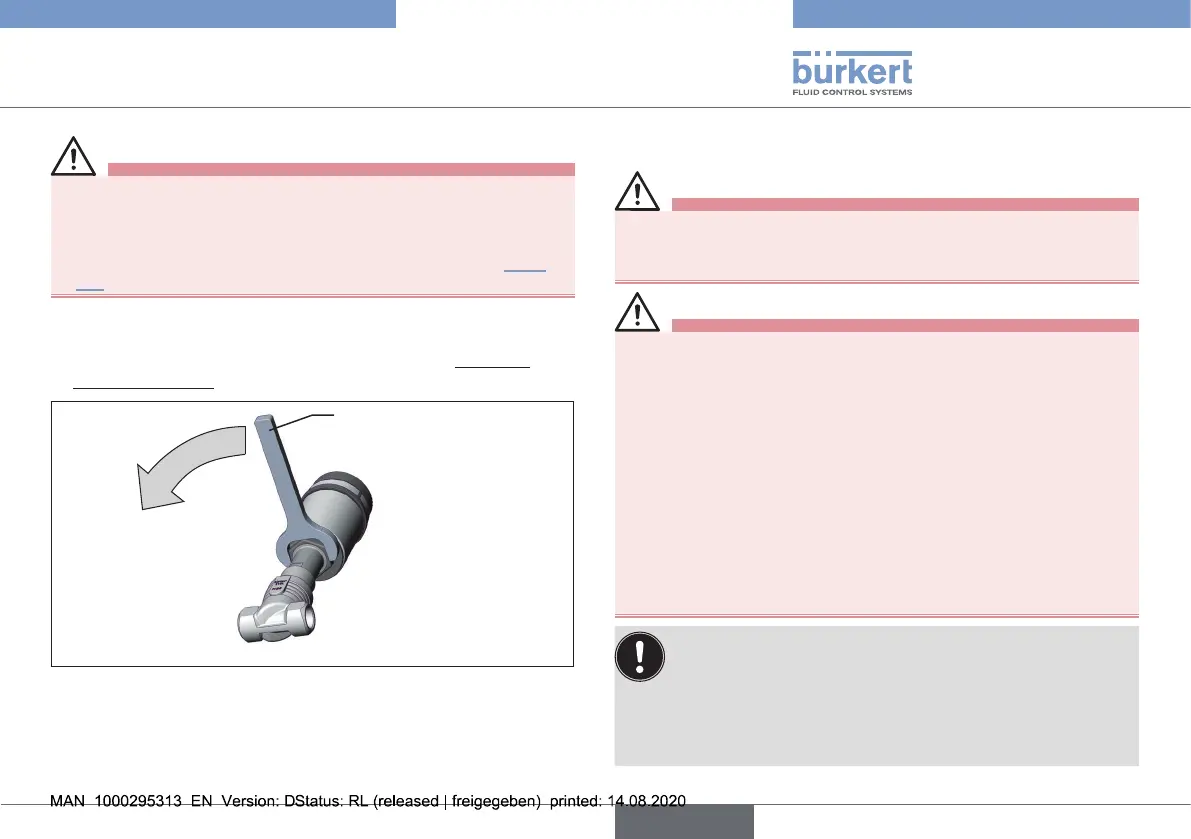

→ Placeasuitableopen-endwrenchonthehexagonheadofthe

actuator.

→ Movetheactuatorintotherequiredpositionbyturning it

counterclockwise(seenfrombelow).

Open-end

wrench

Fig.15: Rotatingwithopen-endwrench

8.4 Pneumatic connection

DANGER!

Risk of injury from high pressure in the system.

▶ Beforelooseninglinesandvalves,turnothepressureand

ventthelines.

WARNING!

Risk of injury due to unsuitable connection hoses.

Hosesthatcannotwithstandthepressureandtemperature

rangecancausehazardoussituations.

▶ Onlyusehosesthatarepermittedforthespeciedpressure

andtemperaturerange.

▶ Notethedatasheetinformationfromthehose

manufacturers.

For control functionI – risk of pilot pressure failure.

WithcontrolfunctionI,thecontrolunitandresetarepneumatic.No

denedpositionisreachedduringapressurefailure.

▶ Toensureacontrolledrestartofthe device,rst apply pilot

pressureandthenactivatethemedium.

Thepneumaticconnectionoftheglobecontrolvalve

canonlybeperformedinconjunctionwiththecorre-

sponding control unit.

Possible control units are:

PositionerType8692,8694and8696

ProcesscontrollerType8693

Type2301

English

Loading...

Loading...