26

Installation

NOTE!

Excessive torque when tightening the fastening screw

cannot ensure the degree of protectionIP65/IP67.

▶ Thefasteningscrewsmustonlybeappliedwithamaximum

torqueof1.5Nm.

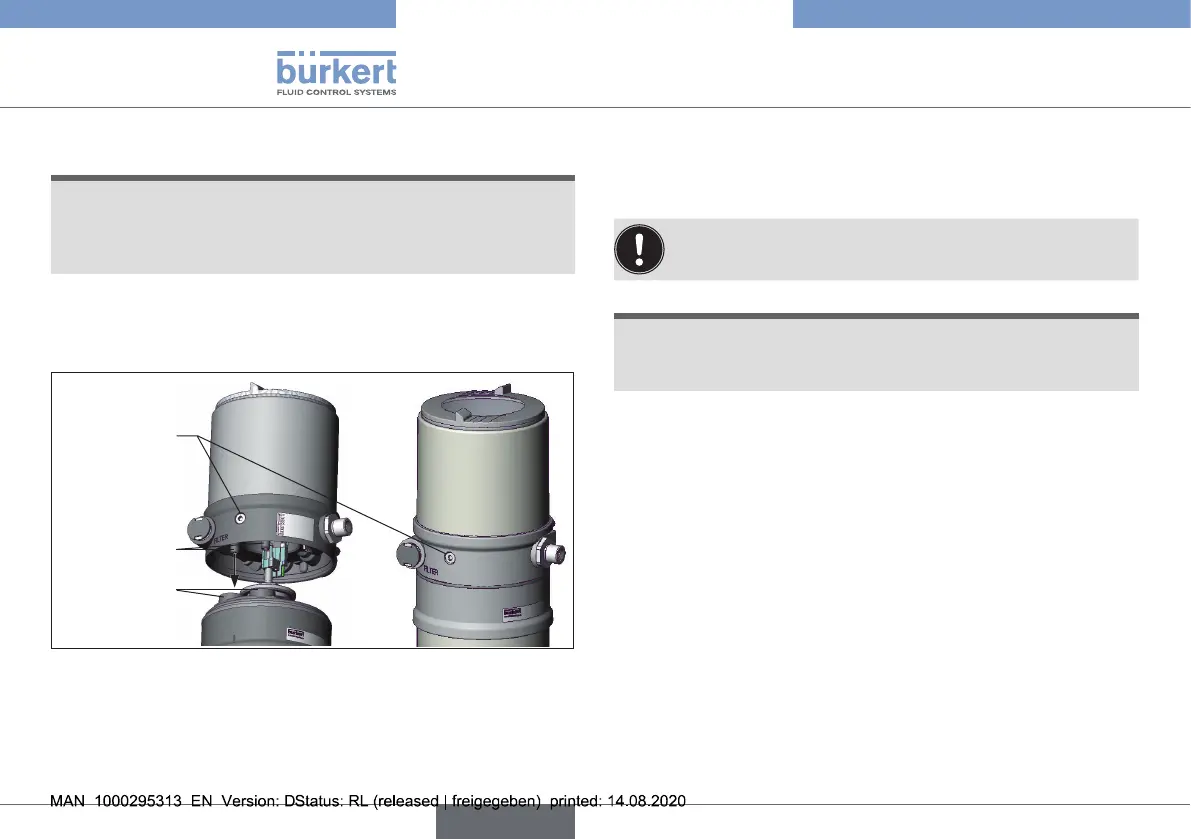

→ Attachthecontrolunittotheactuatorusingthetwolateral

fasteningscrews.Onlylightlytightenthescrews(maximum

torque:1.5Nm).

Connection

piece

Pilot air

ports

Actuator

Fastening

screws(x2),

max.1.5Nm

Fig. 14: Control unit installation

8.3.4 Turning actuator

Thepositionoftheportscanbesmoothlyalignedbyturningthe

actuator360°.

Onlytheactuatorcanberotated.Itisnotpossibletorotate

thecontrolunitagainsttheactuator.

NOTE!

Damage to the valve seat seal or seat contour.

▶ Whenturningtheactuator,thevalvemustbeintheopen

position.

Procedure:

→ Clampvalvebodyinaholdingdevice(onlyforvalveswhich

havenotyetbeeninstalled).

→ For control functionA:

Without control unit:pressurisethepilotairport1withcom-

pressedair(5bar):Valveopens.

With control unit:openthevalveinaccordancewiththeoper-

atinginstructionsofthecontrolunit.

→ Counterwithasuitableopen-endwrenchonthewrenchatof

thenipple.

Type2301

English

Loading...

Loading...