41

Maintenance, cleaning

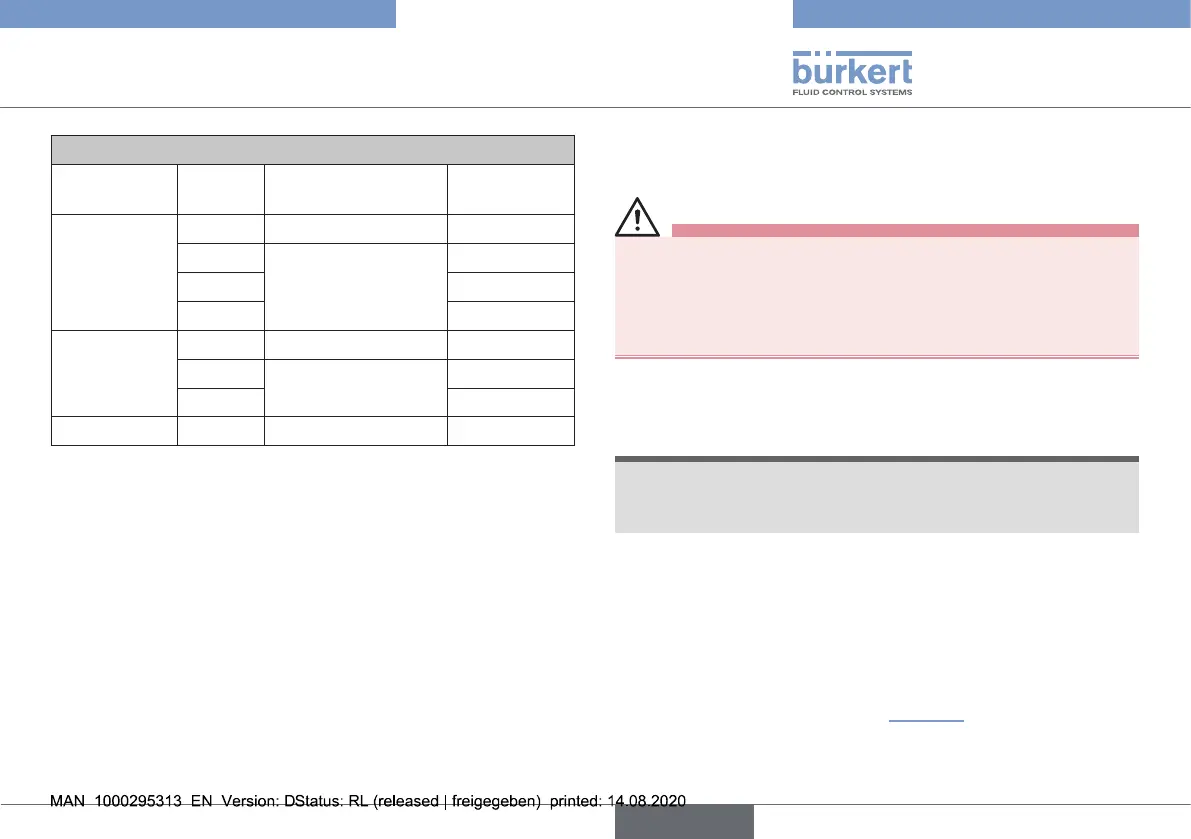

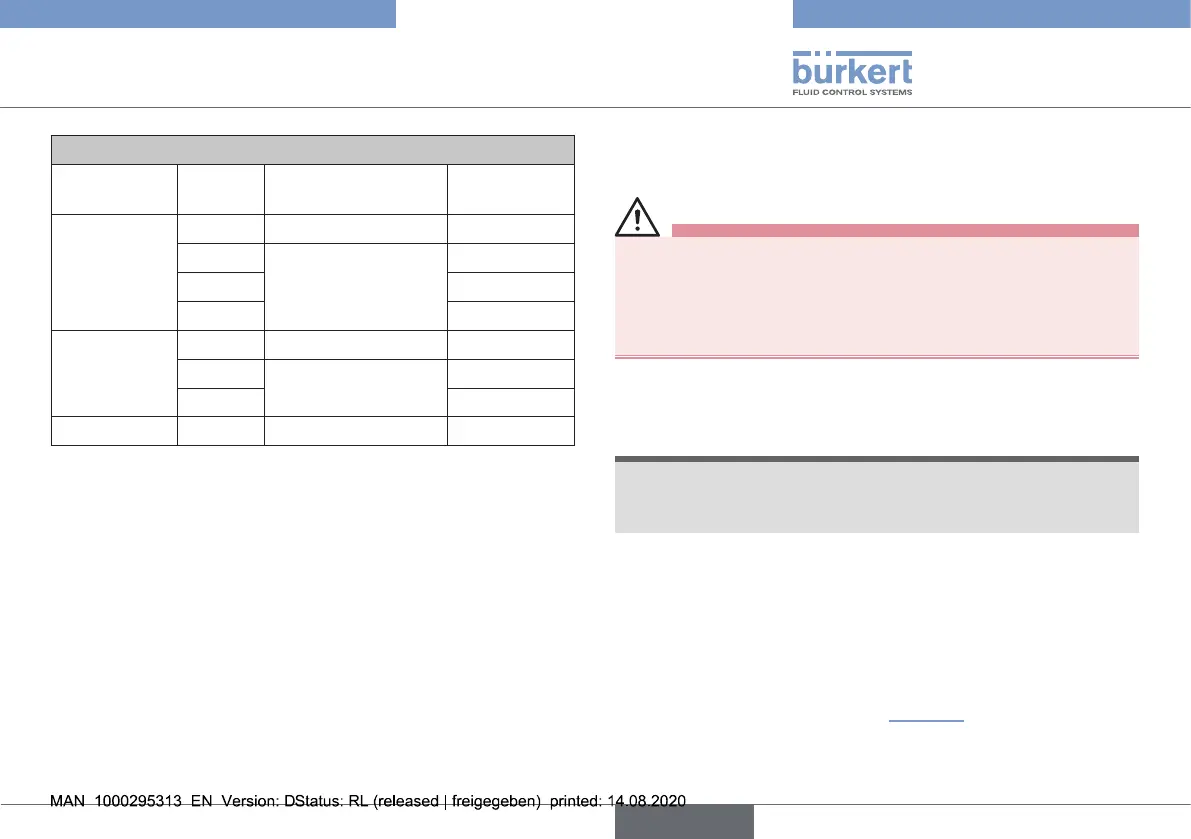

Tightening torques spindle guide

Spindle

diameter

DN Spindle guide

material

Tightening

torque [Nm]

10mm - PEEK 6

10/15 1.4401/1.4404/316L 15

20/25 25

32 50

14mm - PEEK 15

20–25 1.4401/1.4404/316L 25

32–50 60

22mm 65–100 1.4401/1.4404 60

Tab.15: Tighteningtorquesspindleguide

Mount control cone

→ Placecontrolconeonthespindle.

→ Alignboreholesinthecontrolconeandspindle.

→ Supportcontrolconeonthecylindricalpartusingaprismor

somethingsimilar.

→ Setupthespring-typestraightpinandcarefullyhammeritin.

→ Centrethespring-typestraightpinwiththespindleaxis.

Install actuator (with control unit) on the valve body

→ Replacethesealifnecessary.

WARNING!

Risk due to incorrect lubricants.

Unsuitablelubricantmaycontaminatethemedium.Thereisa

riskofexplosioninoxygenapplications.

▶ Forspecicapplications,e.g.oxygenoranalysisapplica-

tions,useapprovedlubricantsonly.

→ Beforere-installation,greasenipplethreadoftheactuator

(e.g.usingKlüberpasteUH196-402fromKlüber).

NOTE!

Damage to the valve seat seal or seat contour.

▶ Whenturningtheactuator,thevalvemustbeintheopen

position.

→ For control function A

Without control unit:pressurisepilotairport1withcom-

pressedair(5bar).Valveopens.

With control unit:Openthevalveinaccordancewiththe

operatinginstructionsofthecontrolunit.

→ Screwactuatorintothevalvebody.

Observetighteningtorque(see“Tab.16”).

Type2301

English

Loading...

Loading...