107 of 166

6.3.4.2 PLC inputs

Some PLC inputs at the I/O interface or on the optional Fieldbuses can be configured with various

functions. Section 4.3.2 “PLC I/O signals” on page 23 contains a full list of the I/O interface assignments

including a summary of which pins can be assigned a configurable function.

The following inputs can be configured by the user:

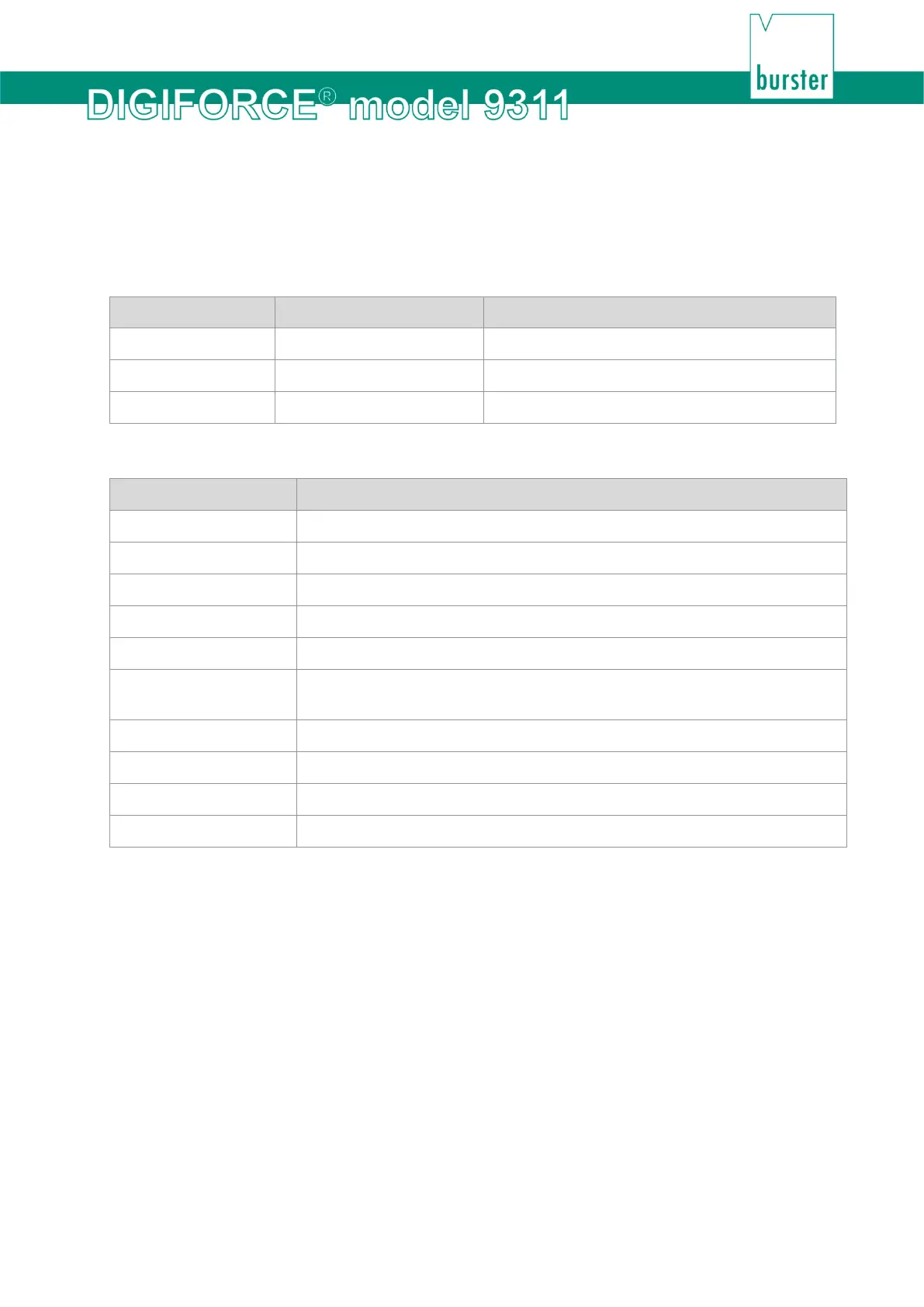

Input Default assignment Meaning

Input 1 (Pin 4) IN_TARE_X Tare the X-channel

Input 2 (Pin 5) IN_RES_STAT Reset the statistics

Input 3 (Pin 6) IN_STEST Run the sensor test

You can assign the following signals to the inputs:

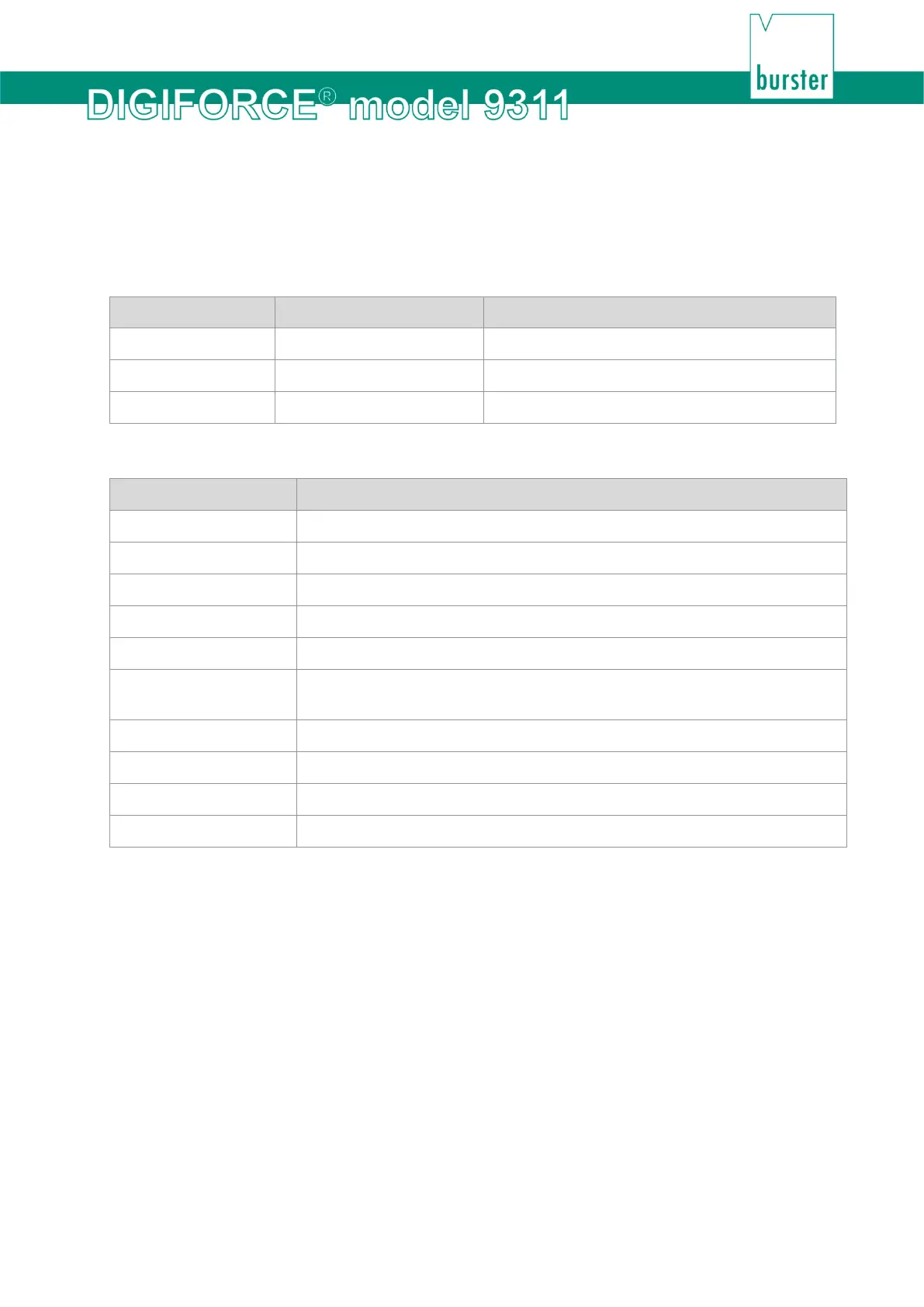

Signal Description

IN_TARE_X Tare the X-channel

IN_TARE_Y Tare the Y-channel

IN_TARE_X+Y Tare the X-channel and Y-channel

IN_RES_STAT Reset the statistics

IN_STEST Run the sensor test

IN_TEST_OP Switch to Graphical test operation (measurement / evaluation without

counter)

IN_ACK Acknowledgement function – acknowledgement of OK and NOK evaluations

IN_ACK_OK Acknowledgement function – acknowledgement of OK evaluations

IN_ACK_NOK Acknowledgement function – acknowledgement of NOK evaluations

IN_ACK_ERROR Acknowledgement of errors/faults (when "OUT_ERROR" = 1)*

*If the DIGIFORCE

®

9311 has a permanent error, the "OUT_ERROR" output cannot be reset by

acknowledging the error.

Loading...

Loading...