EN

28

8.7 Databus connection (optional)

PLC databus connection

The controller can use one of three available databus connections to

connect to the building automation system (optional). The available

data bus connections are:

a)Pronetwithdataexchangeusing“Put/Get”commands

b)Pronetwiththeintegrationoftheozonedeviceintothecustomer

controlsystemusinga“GSD”le

c)ProbusDPwiththeintegrationoftheozonedeviceintothecustomer

controlsystemusinga“GSD”le

The building automation system PLC can use the databus connection

to control and monitor the whole plant:

a) Controlling the ozone generation

–Switchingozonegenerationon/o

– Presetting the ozone level

b) Device monitoring supplies:

– Operating values for the ozone generation

–Operatingvaluesfordryers1+2

– Operating state messages

– Fault messages

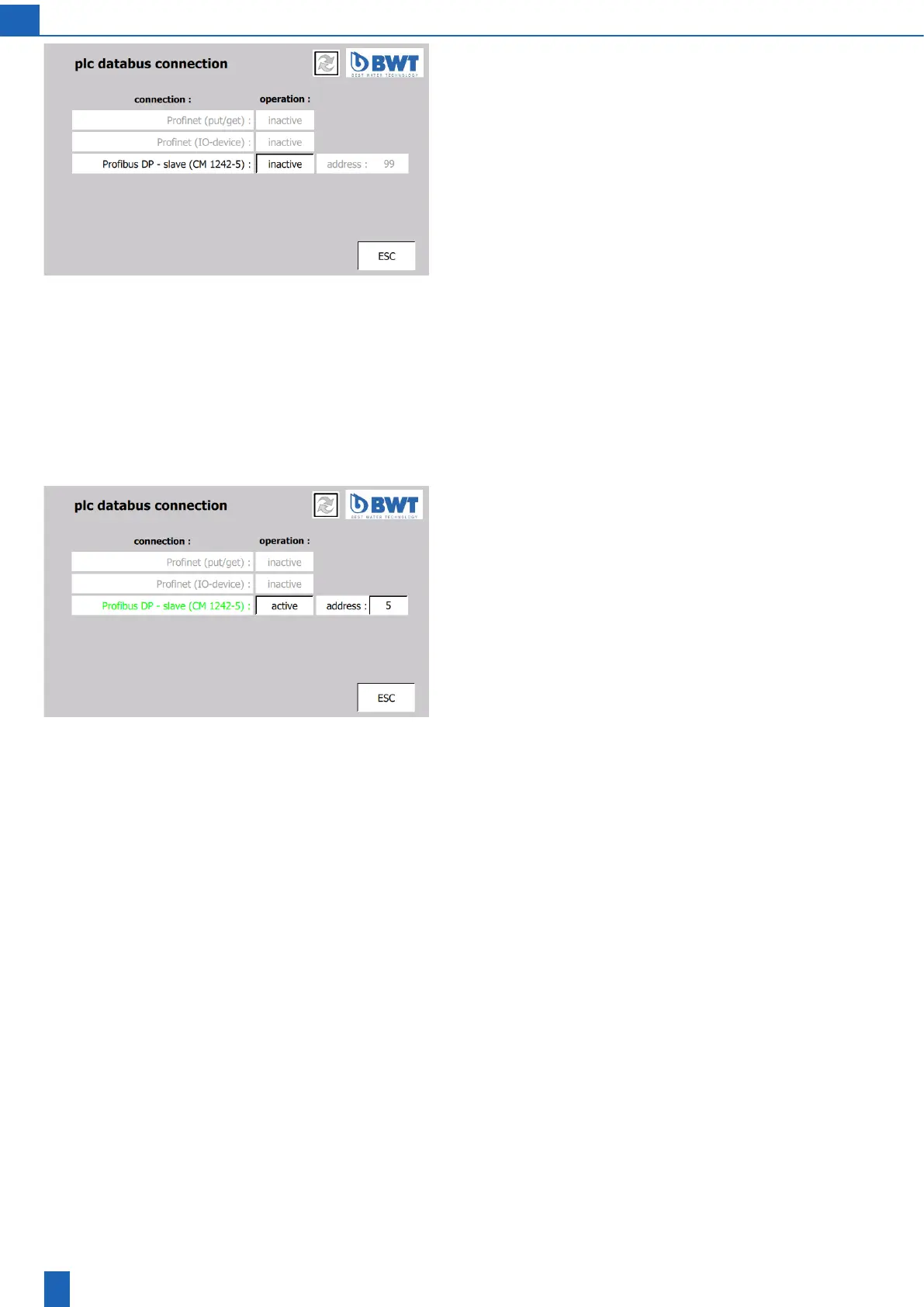

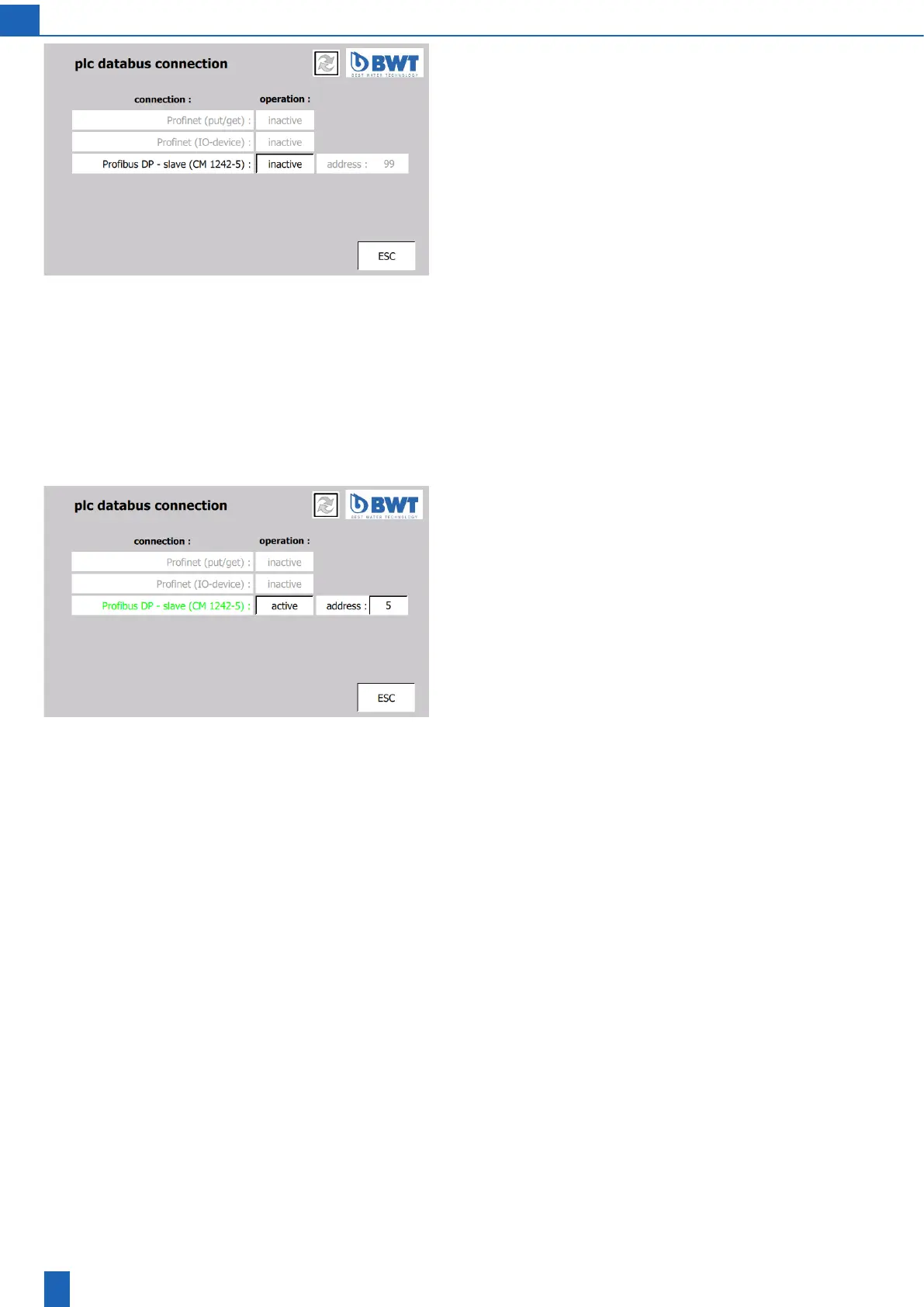

PLC databus connection

The connection is highlighted in colour:

Green = active, red = faulty, black = inactive, grey = not available

To activate it, the user IT (2222) password or service password is

required.

Caution: When activating a Pronet connection between the PLC

andbuildingautomationsystem,thePronetconnectionbetweenthe

PLC and touch panel (TP) may fail because the higher-level building

automation system PLC (= controller) assigns a new IP address to the

ozone device PLC (= device). This new IP address for the PLC must

beconguredintheTPtoconnecttheTPtothePLC.Theconnection

oftheozonedevicetoanexternalPronetmustbeperformedonlyby

a network administrator of the operator (user IT).

Address:ToconnectthedevicetoaProbusDPnetwork,thenetwork

administrator of the operator can enter its specied Probus slave

addressspeciedhere.

Loading...

Loading...