EN

32

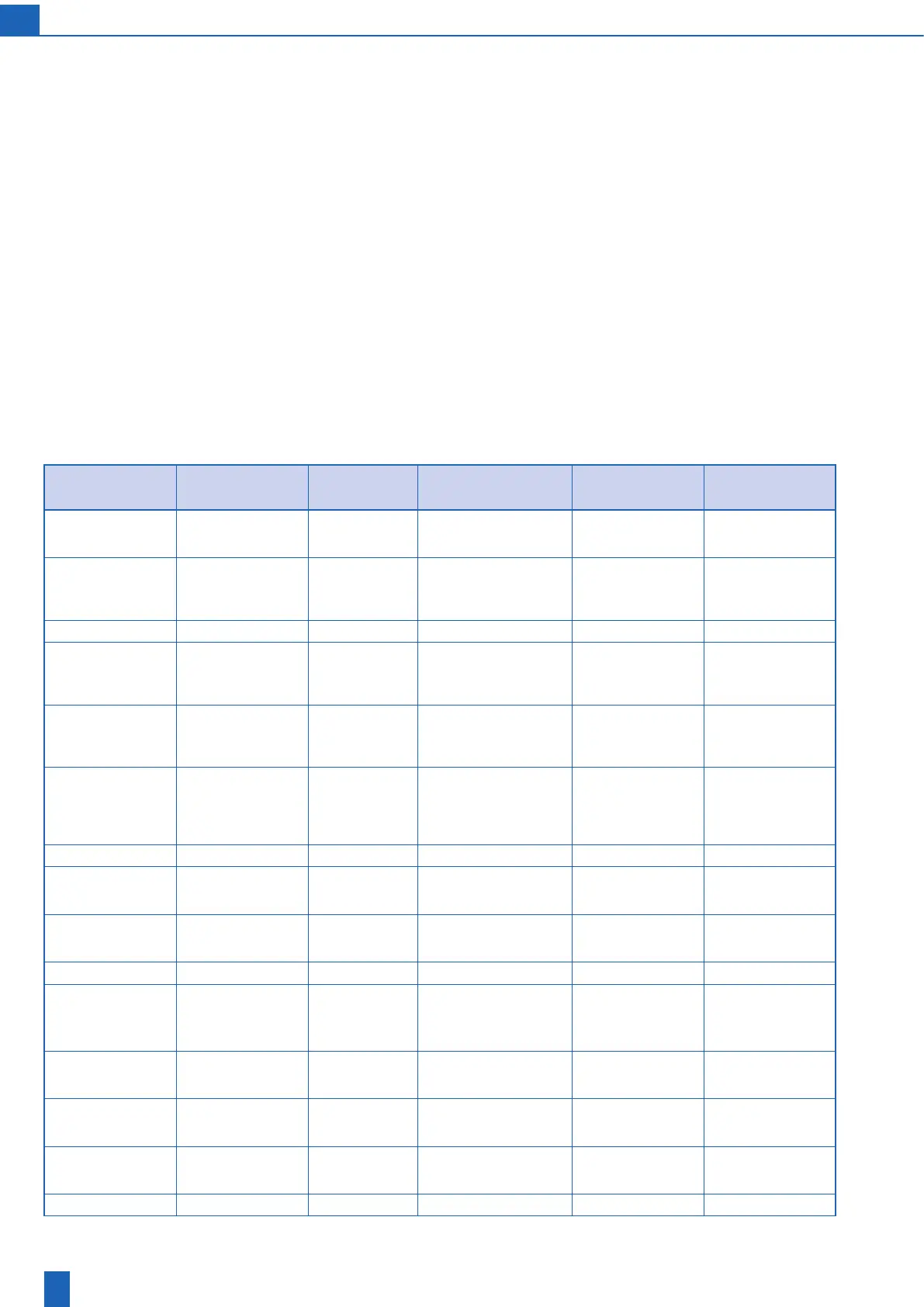

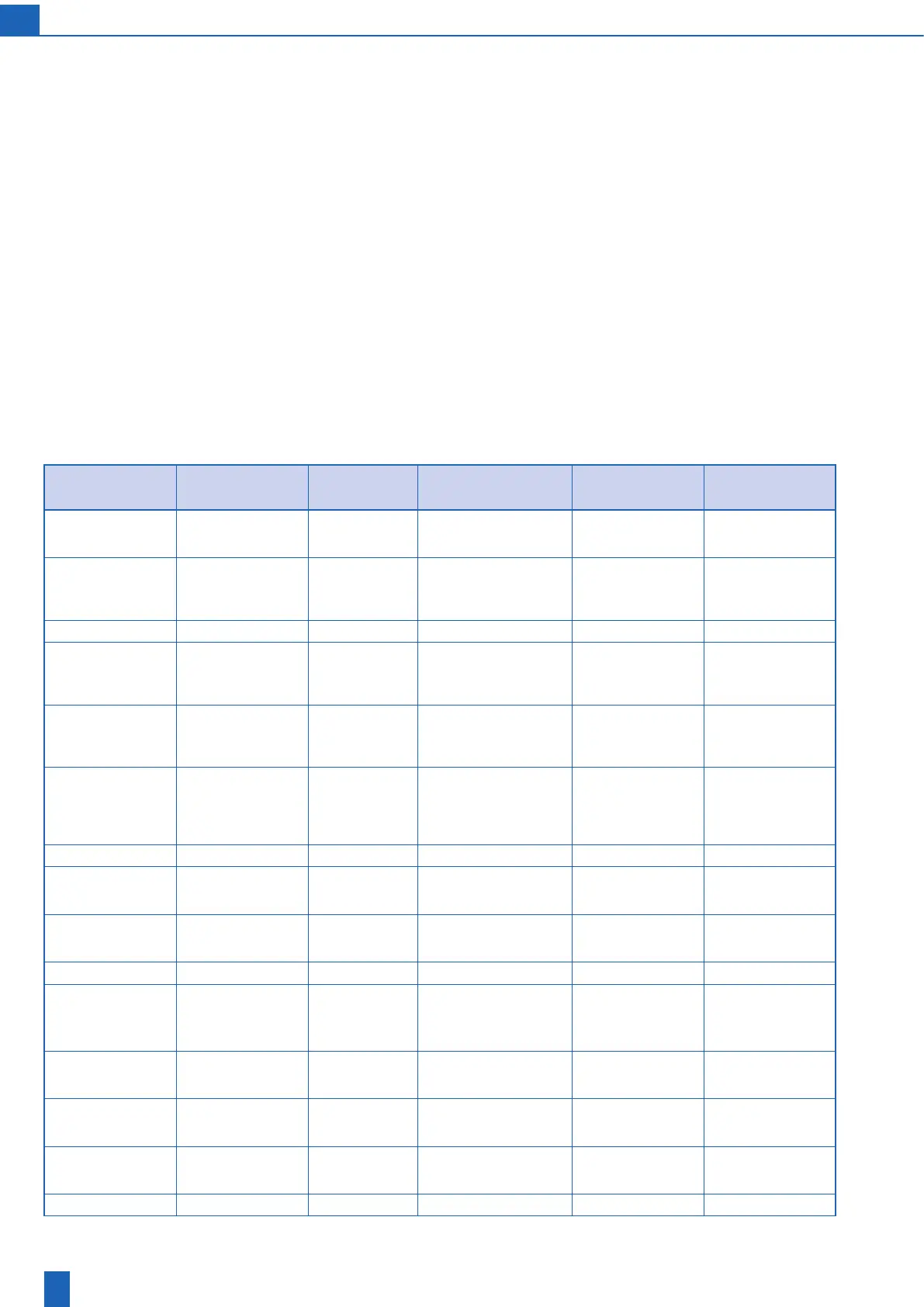

Fault no. Monitored operating

condition

Delayed

actuation

Ozone device reaction Possible cause Remedy

(§5/6) Dryer fault 1/2:

cancellation/end of

regeneration test run

Dryer regeneration - Cancellation of regenerati-

on, dryer is not ready

Manual cancellation of

regeneration

(§7/8) Dryer reset 1/2:

Cancellation of rege-

neration, dryer ready

for operation

Dryer regeneration - Cancellation of regenerati-

on, dryer is ready

Manual dryer reset

during regeneration

(§9 to 17) reserved - - - - -

(§18) PLC hardware

error,conguredhard-

ware does not match

actual hardware

PLC startup - Device is not ready for

operation

Conguredenhance-

ment module is una-

vailable or defective

Checkthecongu-

ration

(§19) PLC fault: 24V

power supply failure

on analogue input mo-

dule SM 1231 (76A1)

All - Device is not ready for

operation

Power supply failure

or module defective

Check for causes

(§20) PLC fault: 24V

power supply failure

on analogue output

module SM 1232

(76A2)

All - Device is not ready for

operation

Power supply failure

or module defective

Check for causes

(§21) reserved - - - - -

(§22) Fault: PLC and

TP version numbers

aredierent

PLC startup - Device is not ready for

operation

DierentPLCandTP

software version

Check the PLC and

TP software versions

(§23) Fault: Date/time

not set

PLC startup - Device is not ready for

operation

PLC had no power

supply for more than

24 days

Set the time

(§24) reserved - - - - -

(§25) Fault: Power

supply phase failure

or network phases

connected in reverse

All 5 sec. a) Ozone generation swit-

chedowithpost-purge

b) Regeneration cancelled

if in the heating phase

Failure of a mains

phase or "left"

("anti-clockwise")

rotaryelddirection

Check phase and

rotaryelddirectionof

rotation

(§26) Fault: Ozone

cabinet door switch

open

Ozone generation - Ozone generation swit-

chedowithout post-

purge

Ozone cabinet door

open

Close the ozone cabi-

net door

(§27) Fault: Emergen-

cy stop pressed

Ozone generation - Ozone generation swit-

chedowithout post-

purge

Emergency stop

pressed

Reset the emergency

stop

(§28) Fault: Ozone

gas warning

Ozone generation - Ozone generation swit-

chedowithout post-

purge

Ozone gas warning Check ozone gas

warning device

(§29) reserved - - - - -

10.2 Fault messages

Any faults that pose a potential hazard for the operator result in imme-

diate disconnection of the high voltage supply, and ozone generation is

stopped. The unit is not purged post-operation by air.

Faults during dryer regeneration do not initially inuence ozone ge-

neration The “Dryer failure” fault message is not displayed until the

operational dryer is exhausted and the other is not ready for operation.

Ozone generation is then stopped.

The dryer loads are calculated as a result of the settings made at the

TP(humidityandairow).Ifaloadingtimethatisshorterthanthere-

generation time of the dryer is calculated using the data, the “Required

dryer capacity too large” fault is displayed. Continuous operation is not

possible.

Ozonegenerationisswitchedowhenfaultsoccurwhichcoulddamage

the unit. However, the unit is purged post-operation (for the duration

set), if this is possible.

If the unit is equipped with an integrated P/PID controller, both the

congurationofthecontrollerandtheoperationofthesignaltransmitter

component of the PLC are monitored in controller operation.

Messagesforfaultswhichoccurandhavebeenrectiedmustbeack-

nowledged on the unit. The unit then continues operation according to

the set operating condition.

You must call our service department to clear faults which require tech-

nical intervention in the unit.

Loading...

Loading...