EN

34

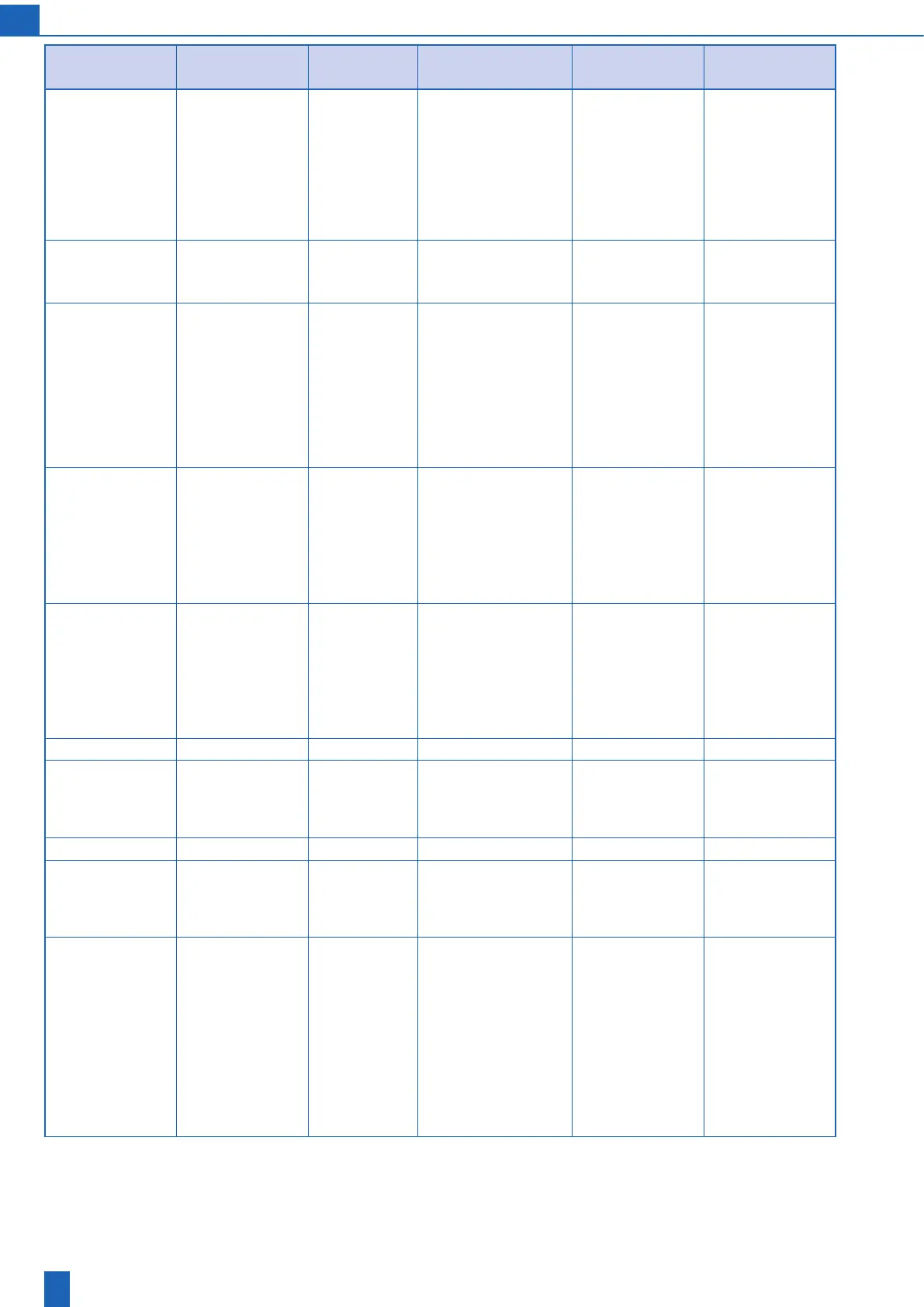

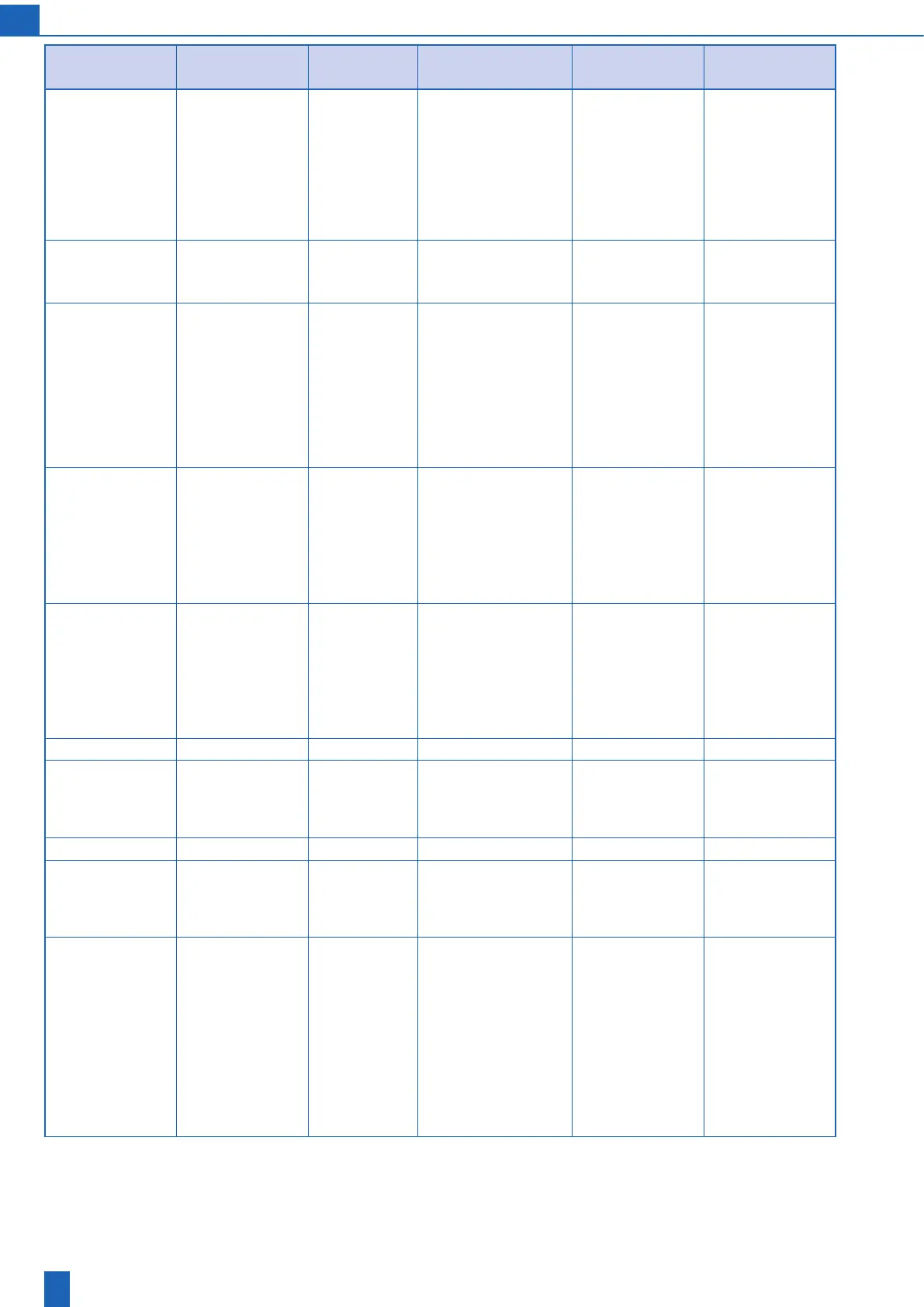

Fault no. Monitored operating

condition

Delayed

actuation

Ozone device reaction Possible cause Remedy

(§37/38) Dryer fault

1/2: Regeneration

blower failure 1M1

Regeneration heating

phase

- Cancellation of regene-

ration, ozone generation

continued until fault §30

reported

a) Regeneration

blower current con-

sumption too high

for protective motor

switch

b) Blower faulty

c) Regeneration air

valve faulty and

closed

a) Check current con-

sumption, set the

motor protection

higher if necessary

b) Check blower

c) Check regeneration

air valve

(§39/40) Dryer fault

1/2: Cancellation of re-

generation, dryer not

ready for operation

Dryer regeneration - Cancellation of regene-

ration, ozone generation

continued until fault §30

reported

Operator/service

request on the panel:

“Cancellation” of rege-

neration

(§41/42) Dryer fault

1/2: Maximum warm-

up time for regenera-

tion air inlet tempera-

ture exceeded, warm-

up temperature on

thermostat 16S1/16S2

not reached

Regeneration warm-

up phase

- Cancellation of regene-

ration, ozone generation

continued until fault §30

reported

a) Heater faulty

b) Air inlet thermos-

tat 16S1/16S2 for

receiving hot air

faulty

c) Regeneration air

valve faulty and

closed

d) Regeneration blo-

wer faulty

Check components

specied

(§43/44) Dryer fault

1/2:On/onumber

on heater 1E1/1E2

lower than 3, switch

temperature on ther-

mostat 16S1/16S2 not

reached

Regeneration warm-

up phase

- Cancellation of regene-

ration, ozone generation

continued until fault §30

reported

a) Heater faulty

b) Air inlet thermostat

16S1/16S2 faulty

c) Regeneration air

valve faulty and

closed

d) Regeneration blo-

wer faulty

Check components

specied

(§45/46) Dryer fault

1/2: Maximum time for

maintaining tempe-

rature exceeded,

end temperature not

reached on thermostat

16S3/16S4

Regeneration heating

phase

- Cancellation of regene-

ration, ozone generation

continued until fault §30

reported

a) Heater faulty

b) Air outlet thermostat

16S3/16S4 faulty

c) Regeneration air

valve faulty and

closed

d) Regeneration blo-

wer faulty

Check components

specied

(§47, 48) reserved - - - - -

(§49 to 62): Fault

messages for design

with double dryer in

accordance with

(§33 to 45)

See (§33 to 45)

(§63, 64) reserved - - - - -

(§65 / 81 / 97 / 113)

Ozone device fault

(circuit 1) / circuit 2 /

3 / 4: Water inrush in

ozone generator

Devices with PVC

ozone generator

=> all

- Ozone generation swit-

chedowithout post-

purge

For PVC ozone gene-

rators: Water inrush

in gas cabinet due to

glass breakage

Rectify cause of water

inrush,

replace ozone genera-

tor if necessary

(§66 / 82 / 98 / 114)

Ozone device fault

(circuit 1) / circuit 2 /

3 / 4: Analogue input,

module SM1231

(76A1), channel AI0 /

AI1 / AI2 / AI3: Signal

negative or > 24 mA

Operating mode for

“Set ozone level” is

set to:

a) “Prop. controller”

or

b) “PID controller”

=> Monitored opera-

ting state

- Ozone generation swit-

chedowithpost-purge

Analogue input signal:

a) Signal cable not

connected to

the correct input

channel or cable is

broken

b) No measurement

signal

c) Measurement signal

polarity reversed

d) Measurement

signal too high

Check the analogue

input signal and con-

nection

Loading...

Loading...