9

Troubleshooting

Machine does not move

even when steering

levers are placed in

FORWARD or

REVERSE positions

Defective turning

・

Parking brake is applied

・ Problem in hydraulic system

・ Failure inside HST

・ Overloaded

・ Insufficient or deteriorated

hydraulic

circuit

・ Clogged oil cooler

・ Dirt in hydraulic circuit

・ Clogged filter element

・ Fluid leaks from hydraulic

system

・ Insufficient discharge from

hydraulic

pump

・ Other

→ Release parking brake

→ See Hydraulic related (See

page 56)

→

Please contact your Canycom

distributor

→ Reduce load

→ Add or change fluid

(See

page 36)

→

Clean

→ Remove dirt

→ Replace (See page 41)

→ Check and repair

→

Please contact your

Canycom

distributor

→

Please contact your

Canycom

distributor

・ Adjustment nut loosened

・ Brake lining worn

・ Water in brake drum

・ Overload

→ Adjust (See page 44)

→ Replace the lining

(

Please

contact your Canycom distributor

)

→ Apply the brake several

times to eliminate water

→ Reduce load

Crawler does not rotate

smoothly

・ Defective wiring

・

Blown bulb

・

Blown fuse

→ Connect

→ Replace

→ Replace (See page 49)

Warning lamp lights up

after engine is started

(1) Charge lamp

(2) Oil lamp

・ Disconnected coupler, wiring

・ Lack of engine oil or

abnormality in lubricating

system

→ Connect

→ Add oil (See page 34)

・

Disconnected terminal for

horn wiring, broken

wiring

・ Blown fuse

→ Connect or repair

→ Replace (See page 49)

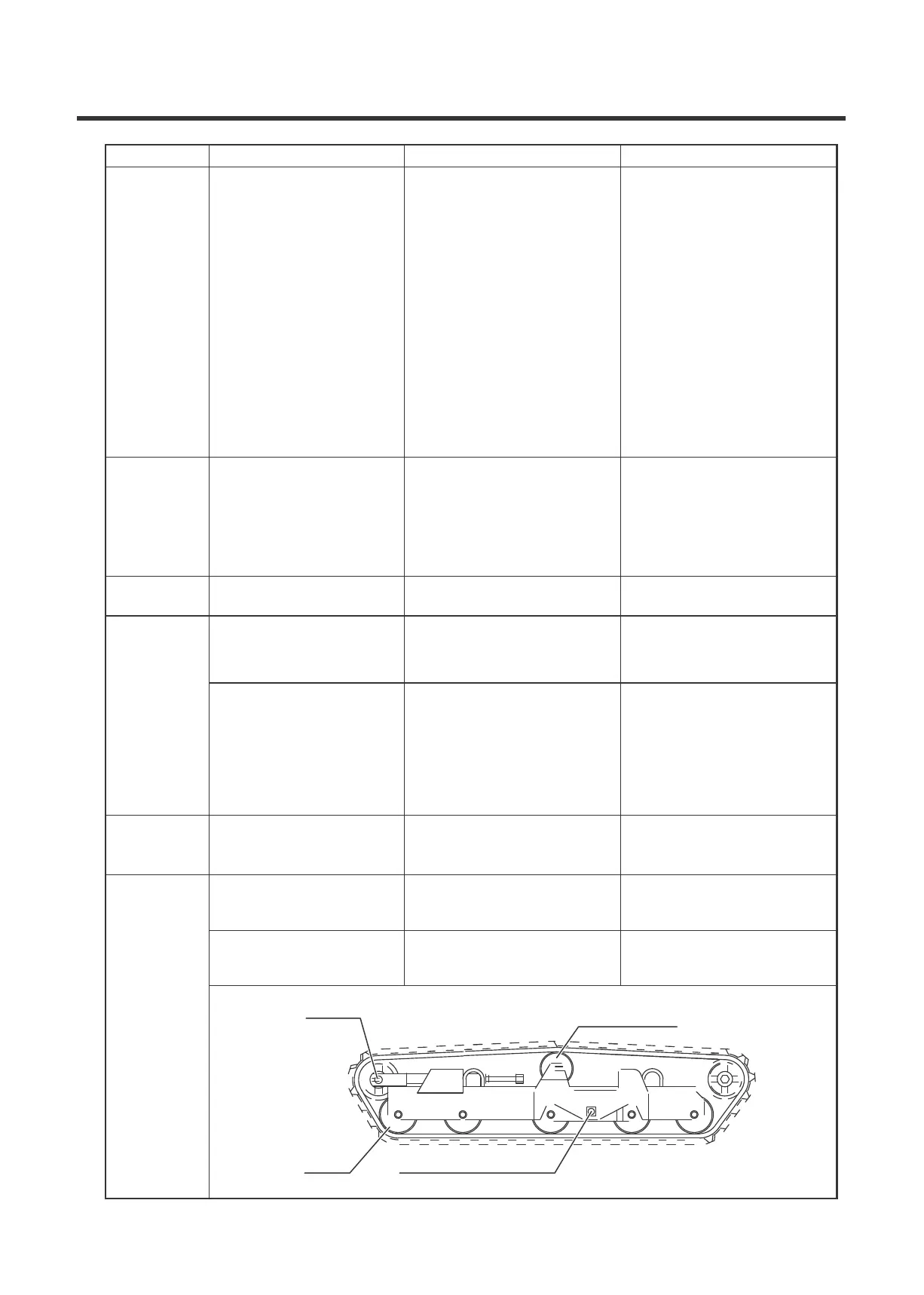

Roller,

Idler,

Upper

roller,

Swing

roller

mounting

pin

→ Replace the defective part

(Please contact your Canycom

distributor

)

→ Replace the defective part

(Please contact your Canycom

distributor

)

Idler

Upper roller

Roller

Swing roller mounting

pin

Loading...

Loading...