7

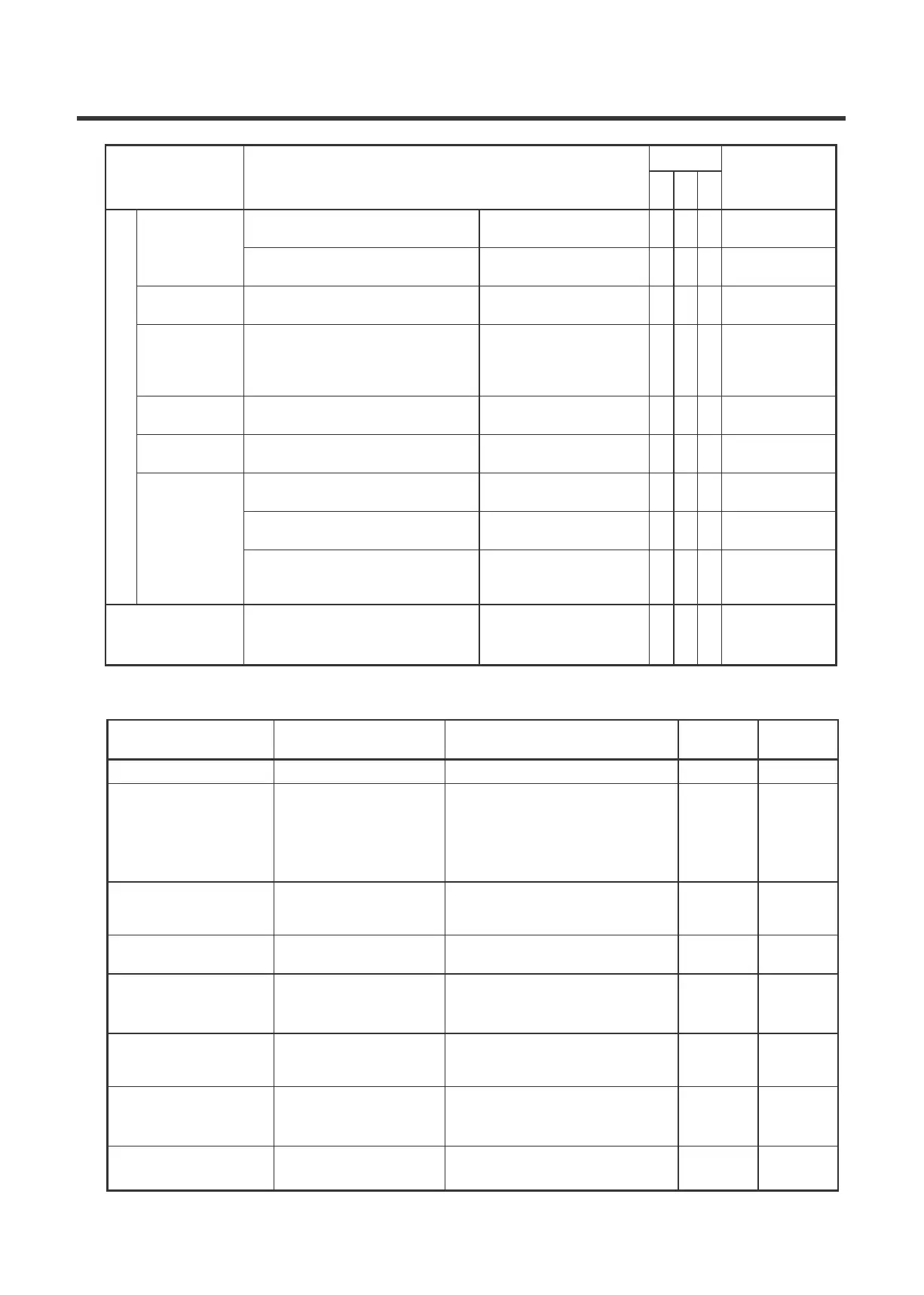

Maintenance

• Check for cracks, deformities, or

corrosion.

No

cracks,

noticeable

deformities,

or

corrosion.

• Check for missing or loose bolts

or nuts.

There must be no loose or

missing mounting bolts or nuts.

•

Check for abnormality in lock open-

ing or closing condition of

covers.

There must be no abnormality

in lock or opening.

•

Check that display plates specified

for

structural regulations and

other

precaution

or

instruction

plates

are

installed without

damage.

Must

be

installed

without

damage.

•

Operate

the

switch

to

check

that

the

horn operates

correctly.

• Check lubrication at all parts.

Must be properly lubri-

cated.

Lubrication:

See page: 37

•

Raise load deck and check condi-

tion

of

support bar when

fixed.

Must be installed

securely.

• Check for curvature or deformi-

ties.

No noticeable curvature

or deformities.

•

Check for cracks or damage in mount

of load deck support

bar.

Use a

flow

detector to check for

cracks.

There must be no

cracks or damage.

•

Operate travel and loading

system

and check

function.

All system must work correctly,

there must be no abnormal

noise, abnormal vibration, or

abnormal generation of heat

.

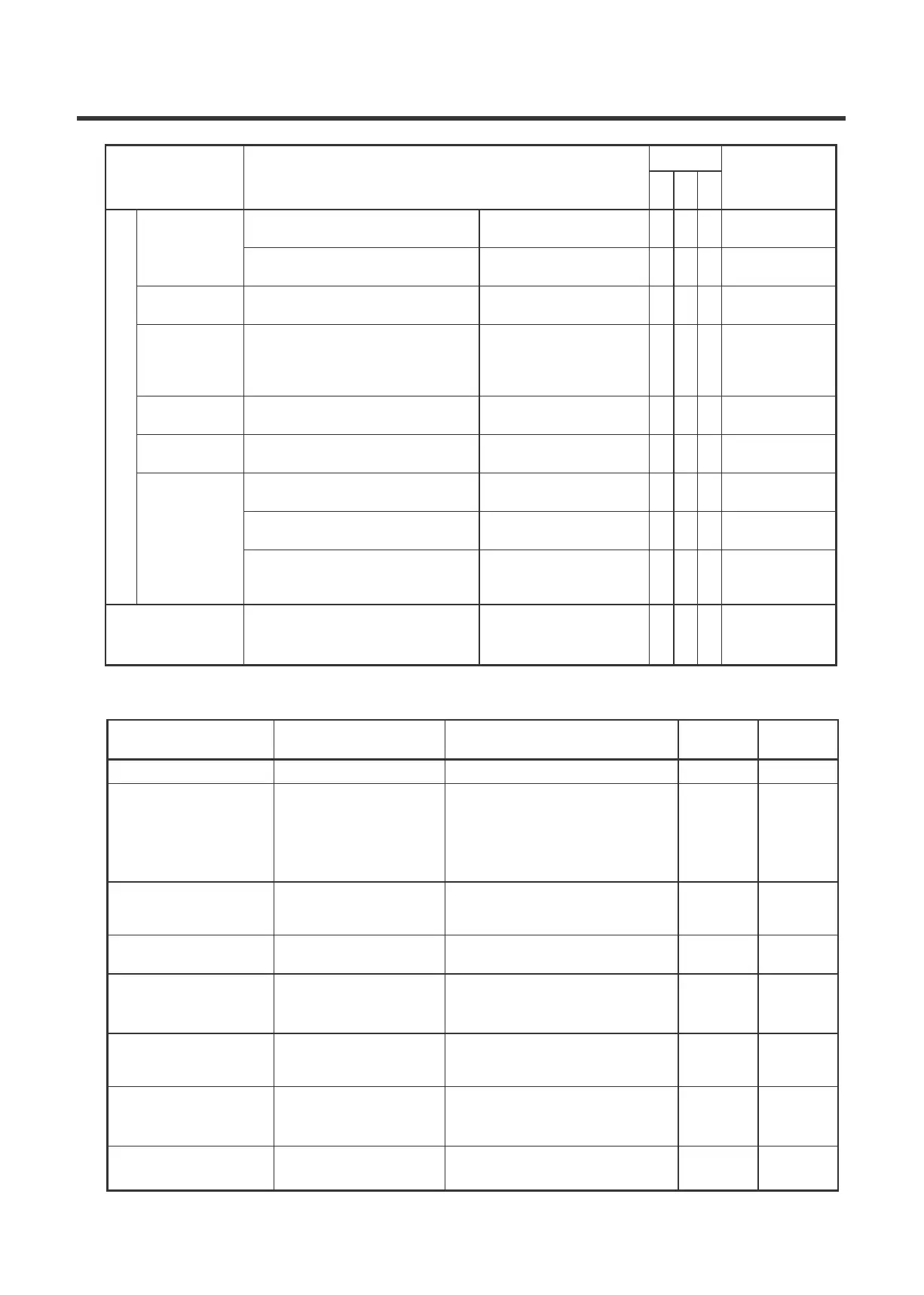

7.2 Fuel, Lubricant, and a Cooling Water Chart

Filling:

Check every

day,

add

when level

is low.

Change:

1st

time:

50 hours.

2nd time on:

every

100

hours.

API

category:

CD

class

or higher

SAE

category: 10W

- 30

1st

time:

50 hours.

2nd time on:

every

100

hours.

Gear

oil

API

category:

GL4 or 5

SAE

category:

# 80

1st time: 50 hours.

2nd time on: every 500 hours.

High viscosity index hydraulic

fluid VG46

Every

6 months.

* For half a year after purchasing,

filling is not required.

Gear

oil

API

category:

GL4 or 5

SAE

category:

# 80

Every

6 months.

* For half a year after purchasing,

greasing is not required.

Check every

day, add

when level

is low.

Change: Every

2 years.

Check every

day, add

when level

is low.

Loading...

Loading...