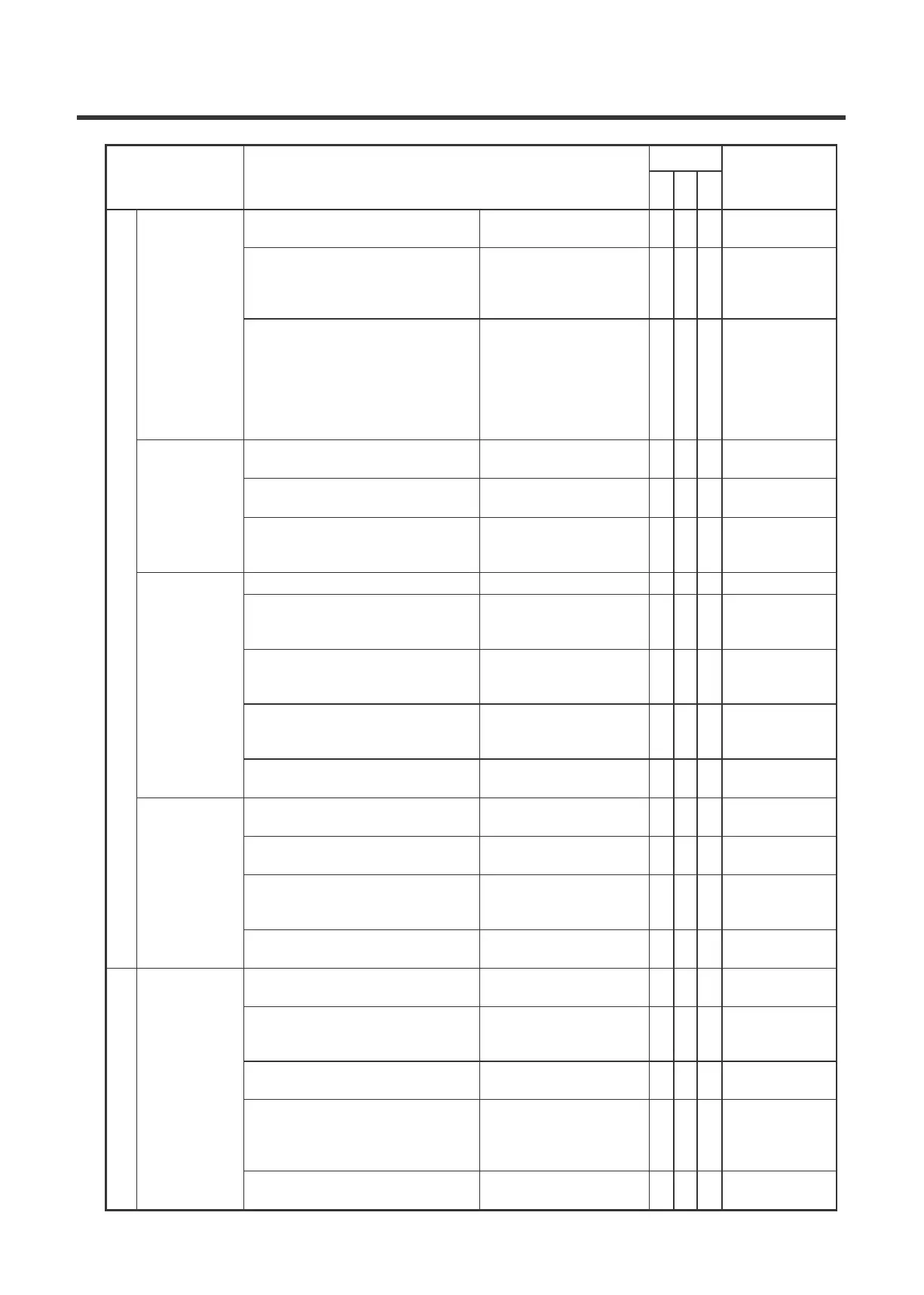

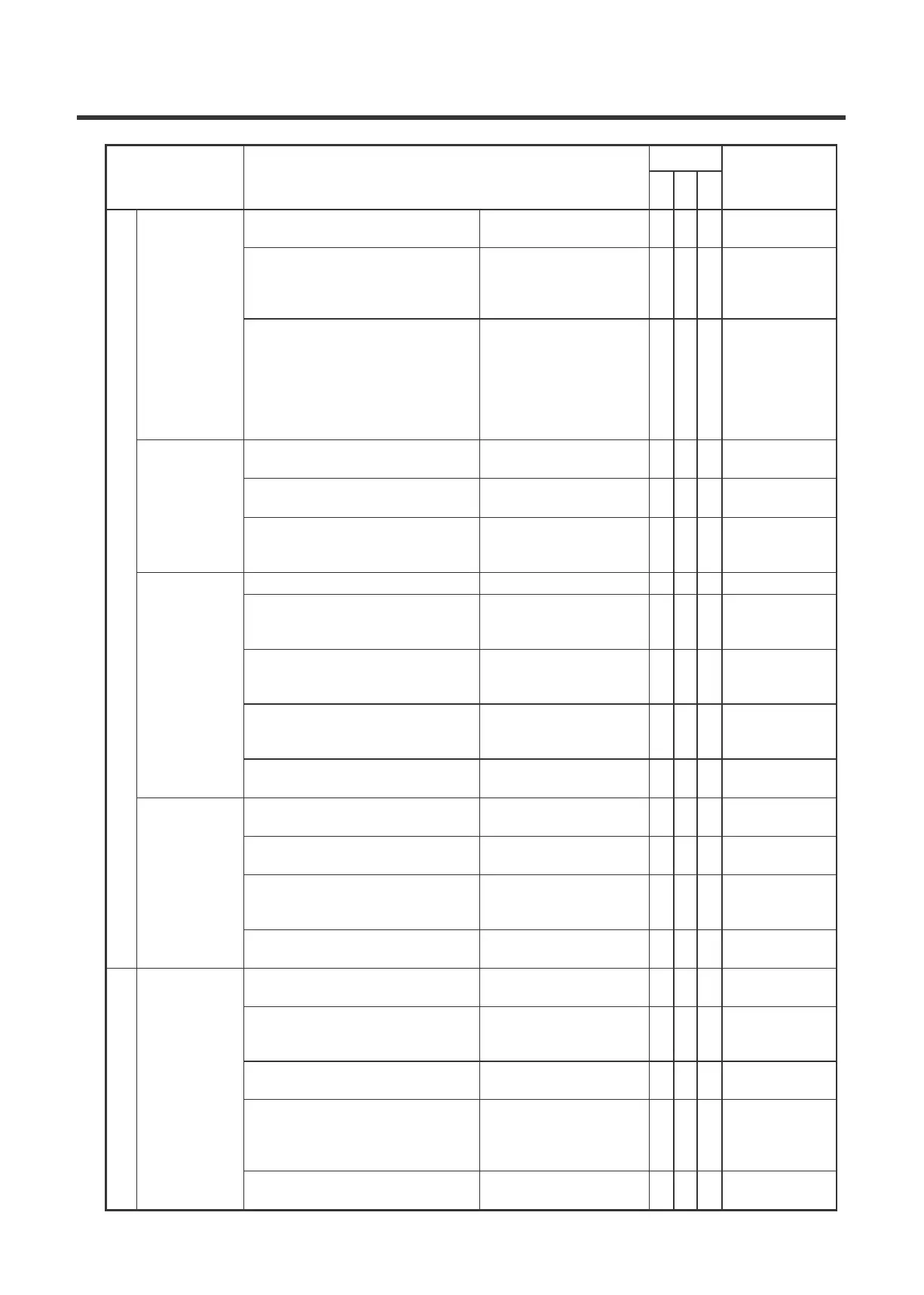

Maintenance

7

•

Check the pipe joint and hose

joint

parts and seal parts for oil leakage.

There must be no oil

leakage.

•

Operate the hydraulic pump,

and

check the pump for abnormal vibra-

tion and noise and abnormal

heat-

ing in unload and loaded

states.

Abnormal vibration and

noise and abnormal

heating must not occur.

•

Apply a load onto the hydraulic pump. Then

check the hydraulic pump under load for

discharge and discharge pressure. This

check may be eliminated when any abnor-

mality does not occur in the inspections for

abnormal vibration and noise and abnormal

heating specified above.

Must be within a

standard value

specified by the

manufacturer.

Piping

(hoses,

high-pressure

pipes)

• Check the piping for cracking,

damage, aging, and twist.

Cracking, damage, aging,

and twist must not

occur.

• Check the pipe joint sections for

oil leakage.

There must be no oil

leakage.

• Check the piping for mounting

state, and bolts and nuts for

looseness and falling.

Mounting state must be

appropriate, and bolts and nuts

must not be loosened nor fallen.

• Check for operating condition.

• Operate the cylinder by extending and

retracting several time. Then check

the seal sections for oil leakage.

There must be no oil

leakage.

• Stop the cylinder by applying a

load. Then check the cylinder

for extension amount.

Extension amount must

be within a standard value

specified by the manufacture.

• Check the cylinder tube and the

cylinder rod for dents, cracking,

bend, and scratch.

Any dent, crack bent,

and scratch must not

occur.

• Check the cylinder mounting

pins for wear and damage.

Excessive

wear and

damage

must not occur.

• By moving the spool, check that

the spool is operated smoothly.

• Check that the control valve is

installed appropriately.

Must be installed

appropriately.

•

Apply a load to the control valve, for example,

by operating the hydraulic cylinder. Then

check the control valve for correct operation.

The hydraulic

cylinder

must be operated normally,

and surely

stopped.

• Check the body, piping, and joint

sections for oil leakage.

There must be no oil

leakage.

•

Check that the bed

of

the truck

can

be

raised and lowered

smoothly.

• Check each part for cracks,

deformation, and wear.

There must be no

cracks,

deformation,

or

wear.

• Check the mounting bolts for

looseness and falling.

There must be no looseness

or falling of the bolts.

•

Check the frame to truck bed

mount-

ing pins and dump cylinder mounting

pins for clearance by moving the

bed

of the truck

vertically.

There must be no

excessive play in the

pin sections.

• Check for cracks, deformation,

and corrosion.

There must be no

cracks

or excessive deformation.

Loading...

Loading...