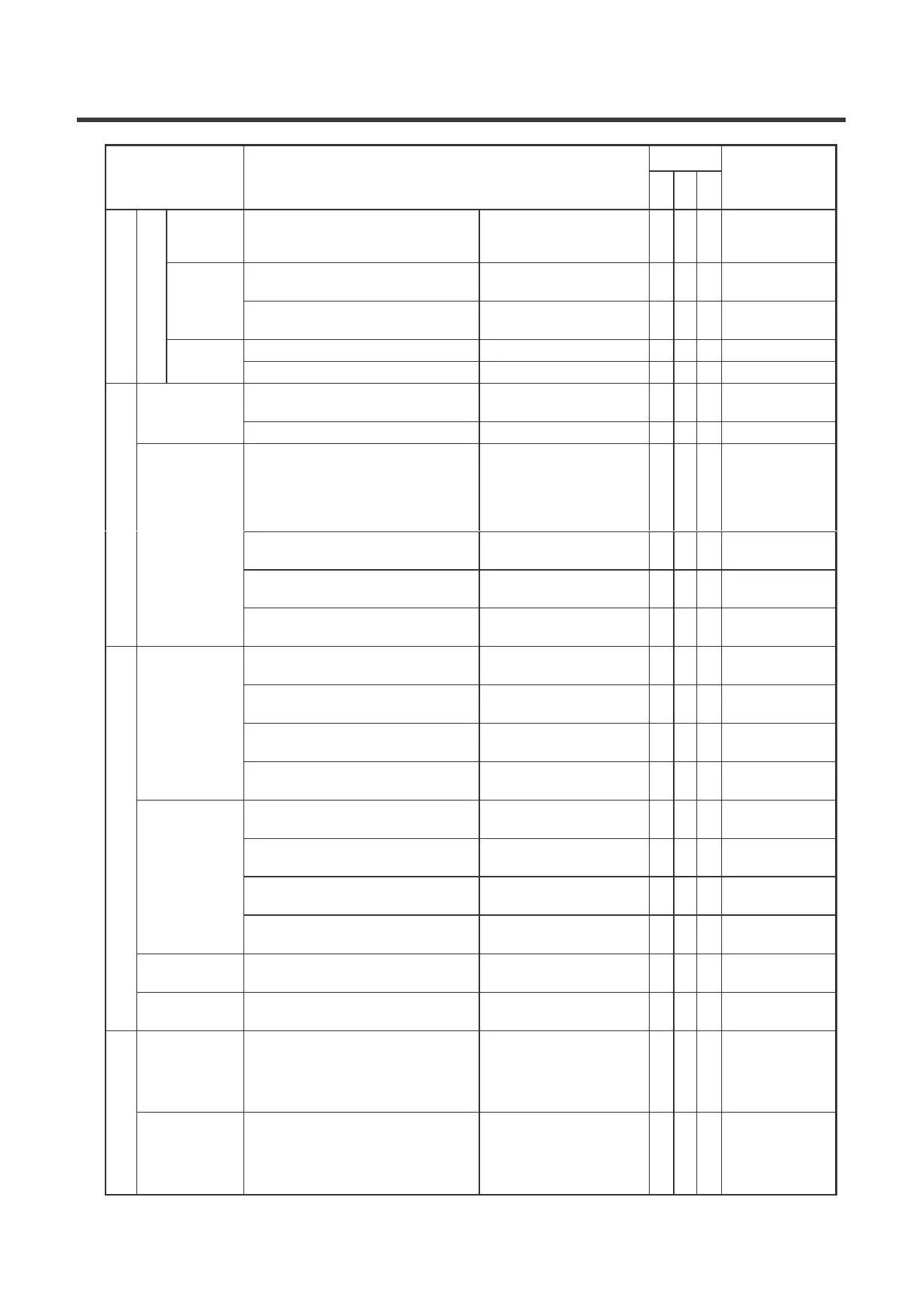

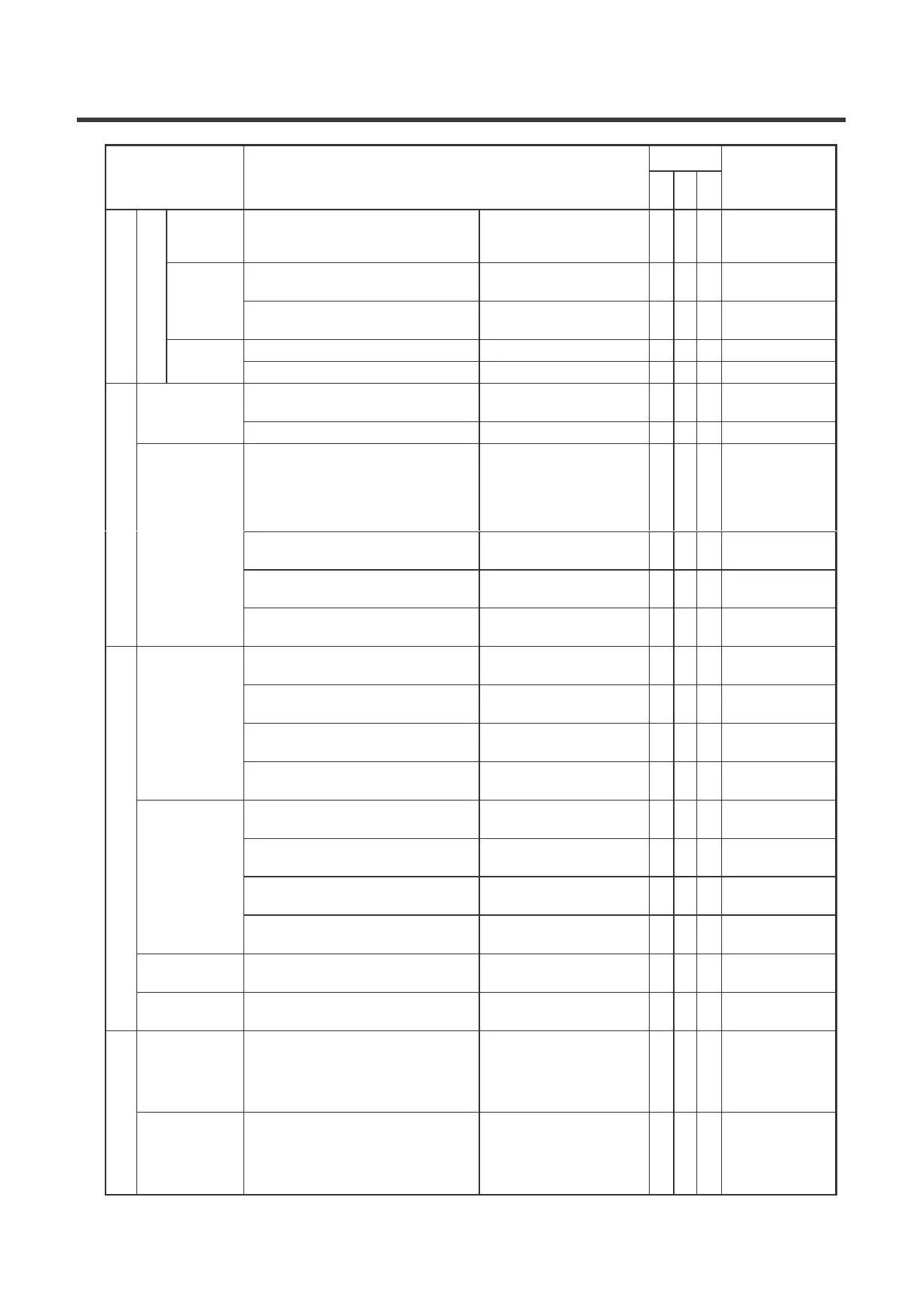

7

Maintenance

• Use Ammeter to check for any

abnormality in function.

Please contact your

Canycom distributor

for inspection.

• Check that electrolyte level is

within specified range.

Must be within specified

range.

Inspection / adding:

See page: 39

• Check for loose or corroded ter-

minals.

There must be no looseness

or marked corrosion.

• Check for loose connections.

There must be no loose connections.

• Check for damaged wiring

• Check for damage and contami-

nation visually.

There must be no

damage

nor abhorrence of lubricant.

• Check the V-belt for tension.

•

Drive machine in

"FORWARD",

"REVERS", and turn left and

right

using travel levers, check

actuation,

check for abnormal noise or abnormal

generation of

heat.

Must work normally,

there must be no

abnormal noise or

abnormal generation of

heat.

• Check oil level inside hydraulic

tank.

Oil level must be cor-

rect.

Inspection / replacement:

See page: 36

There must be no

marked dirt.

Inspection / replacement:

See page: 36

• Check for oil leakage from

around hydraulic tank.

There must be no oil

leakage.

Sprocket,

Idler,

Roller,

Upper

roller

• Check for cracks, deformities,

wear.

No cracks, deformities,

or noticeable wear.

• Drive machine and check for abnormal noise or

abnormal generation of heat from shaft area.

No abnormal noise or

heat.

• Check for loose or missing

mounting bolts and nuts.

There must be no loose

or

missing bolts and

nuts.

• Check for oil leakage from

around axle.

There must be no oil

leakage.

• Check for cuts or damage in

steel cord.

There must be no cuts

or marked damage.

• Check for cuts, deteriorated, or

worn rubber.

There must be no marked cut-

ting, deterioration, or wear.

• Check for missing or broken

core.

There must be no miss-

ing core.

Tension must not be too

loose or too tight.

• Check for deformation and cor-

rosion.

There must be no defor-

mation and

corrosion.

• Check for cracks, deformation,

and damage.

There must

be no crack,

deformation,

or damage.

•

With the brake pedal locked

with

the parking brake lock lever,

check

that machine does not move

when

stopped unloaded

on a slope.

Must be proper parking

effect.

• Check the rods, links, and wires

for damage and the mounting

parts for looseness.

There must be no dam-

age or looseness.

Loading...

Loading...