Modular Standard HP Chiller for Carel driver

Carel code +030221236- Rel. 1.0 dated 7 July 2003

12

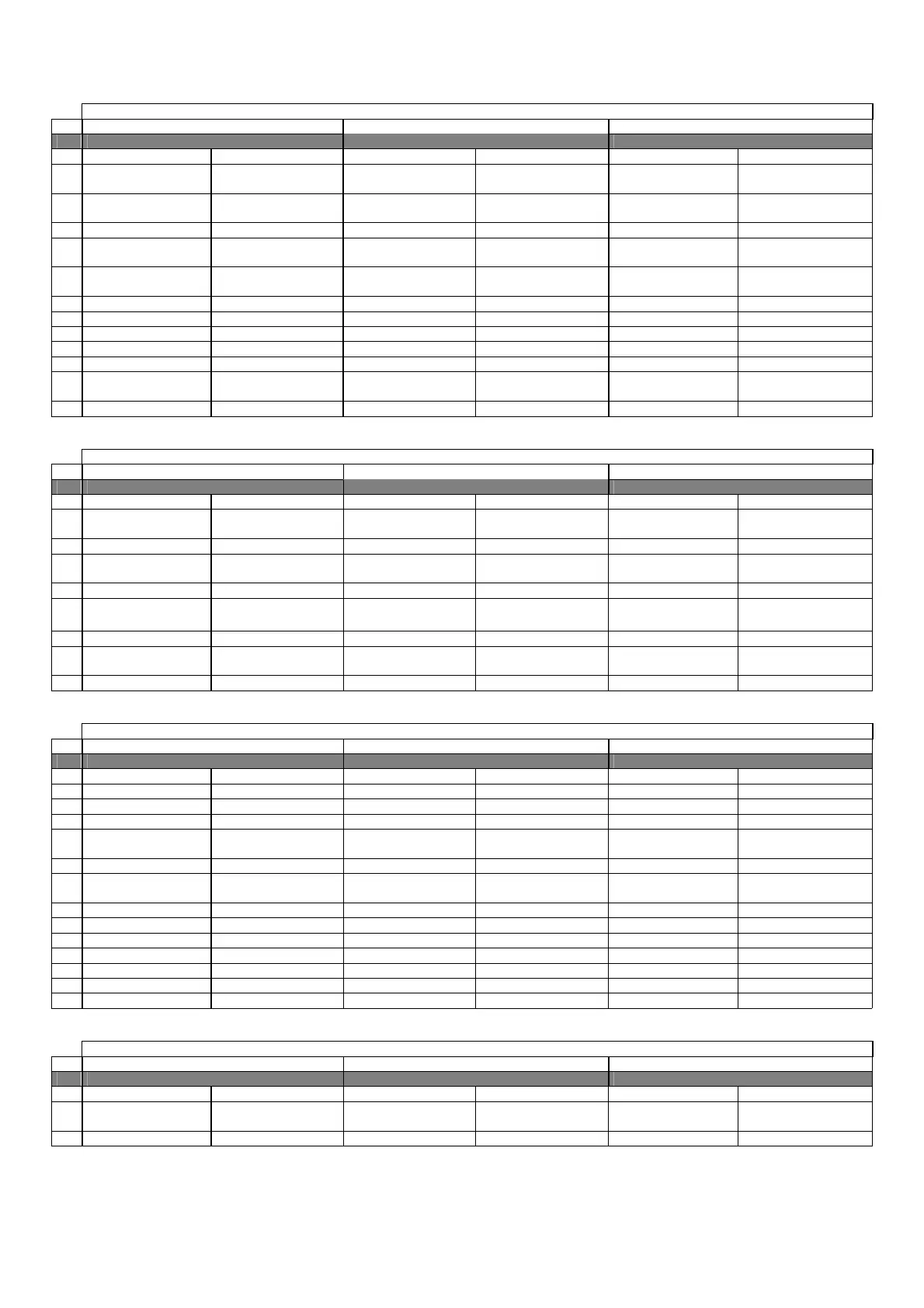

6.5 CHILLER UNIT WITH HEAT PUMP – MACHINE TYPE “4”

6.5.1 DIGITAL INPUTS

Chiller unit with heat pump MACHINE TYPE “4”

N. pCO2 MEDIUM pCO1 MEDIUM pCOC MEDIUM

Master Slave

Master Slave Master Slave

1

Serious alarm Serious alarm

(enablable)

Serious alarm Serious alarm

(enablable)

Serious alarm Serious alarm

(enablable)

2

Evaporator flow-switch Evaporator flow-switch

(enablable)

Evaporator flow-switch Evaporator flow-switch

(enablable)

Evaporator flow-switch Evaporator flow-switch

(enablable)

3

Remote On/Off Remote On/Off Remote On/Off

4

Cooling/heating

selector

Cooling/heating

selector

Cooling/heating

selector

5

Low pressure 1

pressure-switch

Low pressure 2

pressure-switch

Low pressure 1

pressure-switch

Low pressure 2

pressure-switch

Low pressure 1

pressure-switch

Low pressure 2

pressure-switch

6

Oil differential 1 Oil differential 2 Oil differential 1 Oil differential 2 Oil differential 1 Oil differential 2

7

Fan 1 thermal cutout Fan 1 thermal cutout Fan 1 thermal cutout Fan 1 thermal cutout Fan 1 thermal cutout Fan 1 thermal cutout

8

Fan 2 thermal cutout Fan 2 thermal cutout Fan 2 thermal cutout Fan 2 thermal cutout Fan 2 thermal cutout Fan 2 thermal cutout

9

Fan 3 thermal cutout Fan 3 thermal cutout Fan 3 thermal cutout Fan 3 thermal cutout Fan 3 thermal cutout Fan 3 thermal cutout

10

Pump thermal cutout Pump thermal cutout Pump thermal cutout

11

High pressure 1

pressure-switch

High pressure 2

pressure-switch

High pressure 1

pressure-switch

High pressure 2

pressure-switch

High pressure 1

pressure-switch

High pressure 2

pressure-switch

12

Comp. 1 thermal cutout Comp. 2 thermal cutout Comp. 1 thermal cutout Comp. 2 thermal cutout Comp. 1 thermal cutout Comp. 2 thermal cutout

6.5.2 ANALOGUE INPUTS

Chiller unit with heat pump MACHINE TYPE “4”

N. pCO2 MEDIUM pCO1 MEDIUM pCOC MEDIUM

Master Slave

Master Slave Master Slave

1

Circ. 1 condenser

temperature

Circ. 2 condenser

temperature

Outside set point Water inlet temperature

2

Water outlet temp.1 Water outlet temp.2

3

Circuit 1 high pressure

transducer

Circuit 2 high pressure

transducer

Circ. 1 condenser

temperature

Circ. 2 condenser

temperature

4

Water inlet temperature

5

Water outlet temp.1 Water outlet temp.2

Water inlet

temperature

Outside set-point

6

Outside set-point Water outlet temp.1 Water outlet temp.2

7

Circuit 1 high pressure

transducer

Circuit 2 high pressure

transducer

Circ. 1 condenser

temperature

Circ. 2 condenser

temperature

Circuit 1 high pressure

transducer

Circuit 2 high pressure

transducer

8

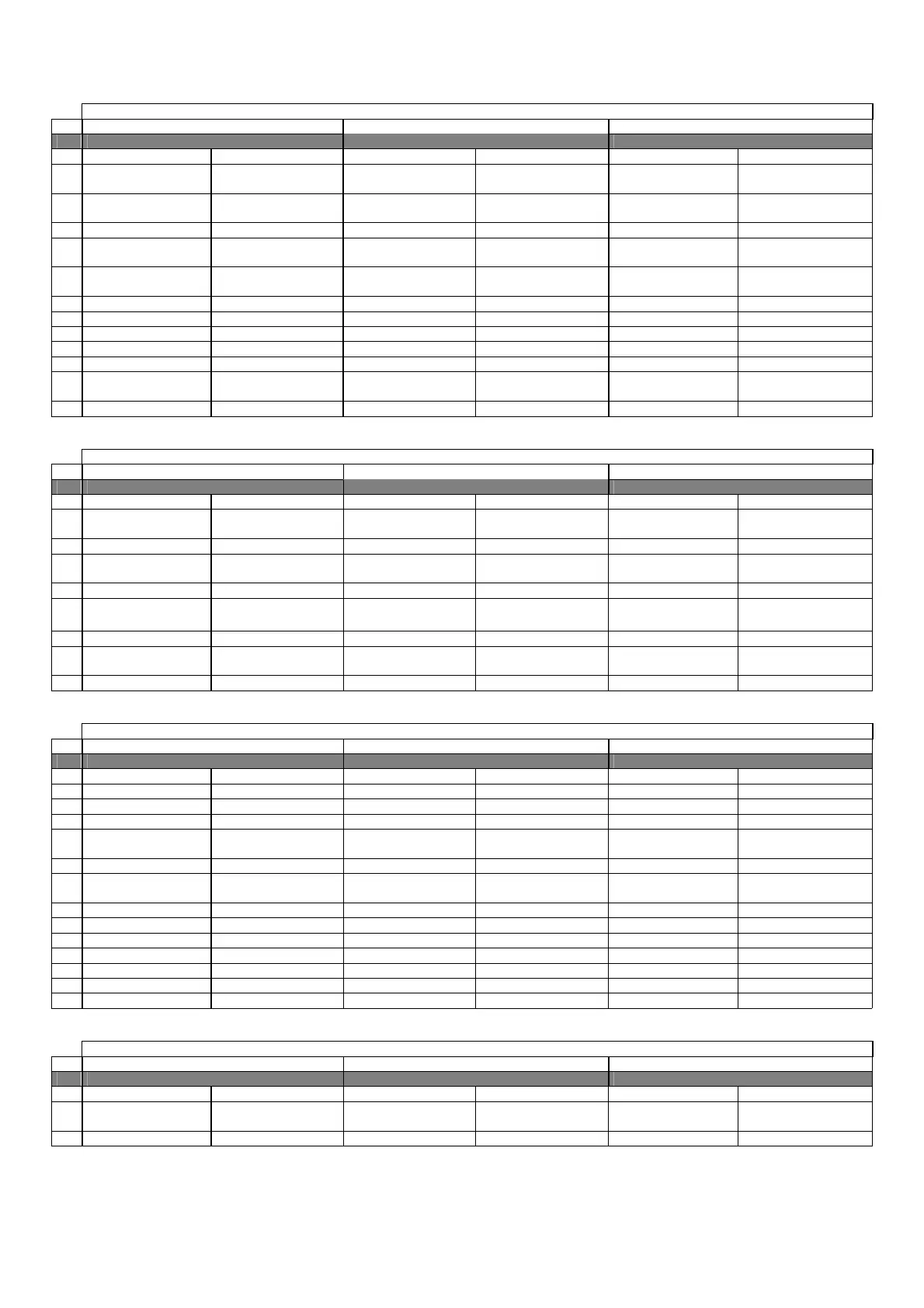

6.5.3 DIGITAL OUTPUTS

Chiller unit with heat pump MACHINE TYPE “4”

N. pCO2 MEDIUM pCO1 MEDIUM pCOC MEDIUM

Master Slave

Master Slave Master Slave

1

Circulation pump Circulation pump Circulation pump

2

Comp. 1 winding A Comp. 2 winding A Comp. 1 winding A Comp. 2 winding A Comp. 1 winding A Comp. 2 winding A

3

Comp. 1 winding B Comp. 2 winding B Comp. 1 winding B Comp. 2 winding B Comp. 1 winding B Comp. 2 winding B

4

Circuit 1 liquid

solenoid

Circuit 2 liquid solenoid Circuit 1 liquid solenoid Circuit 2 liquid solenoid Circuit 1 liquid

solenoid

Circuit 2 liquid solenoid

5

Circuit 1 4-way valve Circuit 2 4-way valve Circuit 1 4-way valve Circuit 2 4-way valve Circuit 1 4-way valve Circuit 2 4-way valve

6

Comp. 1 capacity stage

1

Comp. 2 capacity stage 1 Comp. 1 capacity stage

1

Comp. 2 capacity stage 1 Comp. 1 capacity stage

1

Comp. 2 capacity stage 1

7

Comp. 1 capacity stage 2 Comp. 2 capacity stage 2 Comp. 1 capacity stage 2 Comp. 2 capacity stage 2 Comp. 1 capacity stage 2 Comp. 2 capacity stage 2

8

Comp. 1 capacity stage 3 Comp. 2 capacity stage 3 Comp. 1 capacity stage 3 Comp. 2 capacity stage 3 Comp. 1 capacity stage 3 Comp. 2 capacity stage 3

9

Circuit 1 fan 2 Circuit 2 fan 2 Circuit 1 fan 2 Circuit 2 fan 2 Circuit 1 fan 2 Circuit 2 fan 2

10

Antifreeze heater Antifreeze heater Antifreeze heater Antifreeze heater Antifreeze heater Antifreeze heater

11

General alarm General alarm General alarm General alarm General alarm General alarm

12

Circuit 1 fan 1 Circuit 2 fan 1 Circuit 1 fan 1 Circuit 2 fan 1 Circuit 1 fan 1 Circuit 2 fan 1

13

Circuit 1 fan 3 Circuit 2 fan 3 Circuit 1 fan 3 Circuit 2 fan 3 Circuit 1 fan 3 Circuit 2 fan 3

6.5.4 ANALOGUE OUTPUTS

Chiller unit with heat pump MACHINE TYPE “4”

N. pCO2 MEDIUM pCO1 MEDIUM pCOC MEDIUM

Master Slave

Master Slave Master Slave

1

Circuit 1 fan speed

control

Circuit 2 fan speed

control

Circuit 1 fan speed

control

Circuit 2 fan speed

control

Circuit 1 fan speed

control

Circuit 2 fan speed

control

2

Loading...

Loading...