Modular Standard HP Chiller for Carel driver

Carel code +030221236- Rel. 1.0 dated 7 July 2003

22

10 ELECTRONIC EXPANSION VALVE

The EV Driver module for piloting the electronic expansion valves (EEV) for the pLAN network, makes it possible to control intake

superheating to enable the refrigerating unit to operate more efficiently and with greater versatility.

We say efficiently, because by improving and stabilising the flow of refrigerant to the evaporator, we increases the system's overall

performance, while guaranteeing safety (low pressure pressure switch less frequently tripped, fewer returns of liquid refrigerant to the

compressor,…). Furthermore, if the EEV is correctly sized, use of condensation pressure (or evaporation pressure,) either floating or at low set-

point, considerably increases the system's efficiency, while ensuring lower energy consumption and greater refrigerating yield.

It is versatile, because the electronic expansion valve makes it possible to serve refrigerating units with a lower refrigerating capacity and in

operating conditions which may differ considerably from each other.

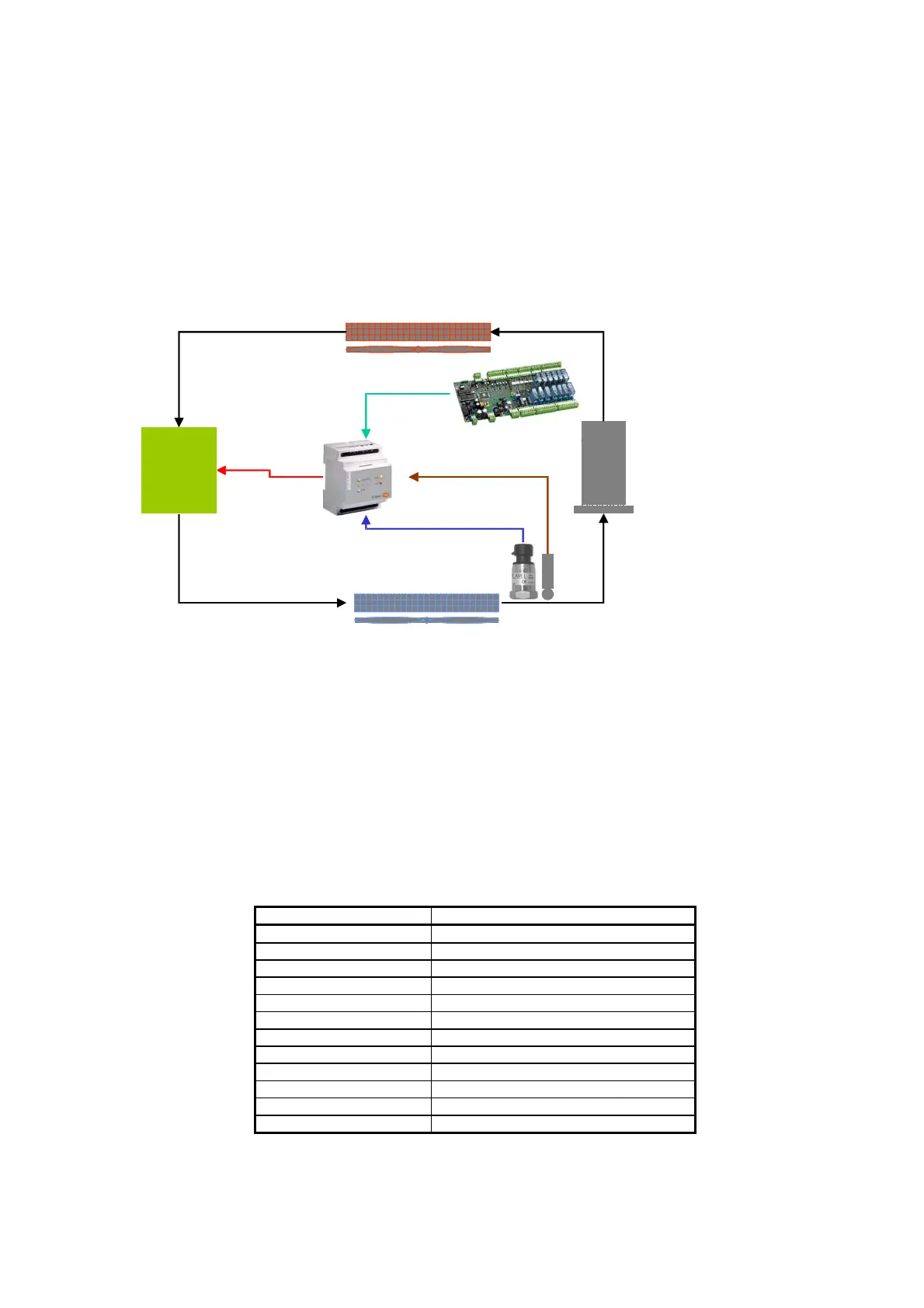

Using an expansion valve entails the installation not only of the EVDriver and the expansion valve itself, but also of a temperature sensor and a

pressure transducer, both located on the refrigerating side at the end of the evaporator (on the compressor's intake pipe). Consult the following

diagram for a better understanding of the system's typical lay-out.

The basic principle of the new control algorithm is to reach the superheating set-point quickly.

In this light, these are the priorities to be considered for optimal control of the refrigerating system: obtaining a high, constant refrigerating yield

rather than very low, stable superheating.

The heart of the control is a PID control with settable coefficients for superheating.

These are the additional controls: LOW (Low superheating with integral time and adjustable threshold)

LOP (Low evaporation pressure, operating in transients only, with integral time and

adjustable threshold)

MOP (High evaporation pressure with integral time and adjustable threshold)

HiTcond (High condensation pressure, enablable only with the condensation pressure probe

read by pCO, with integral time and adjustable threshold)

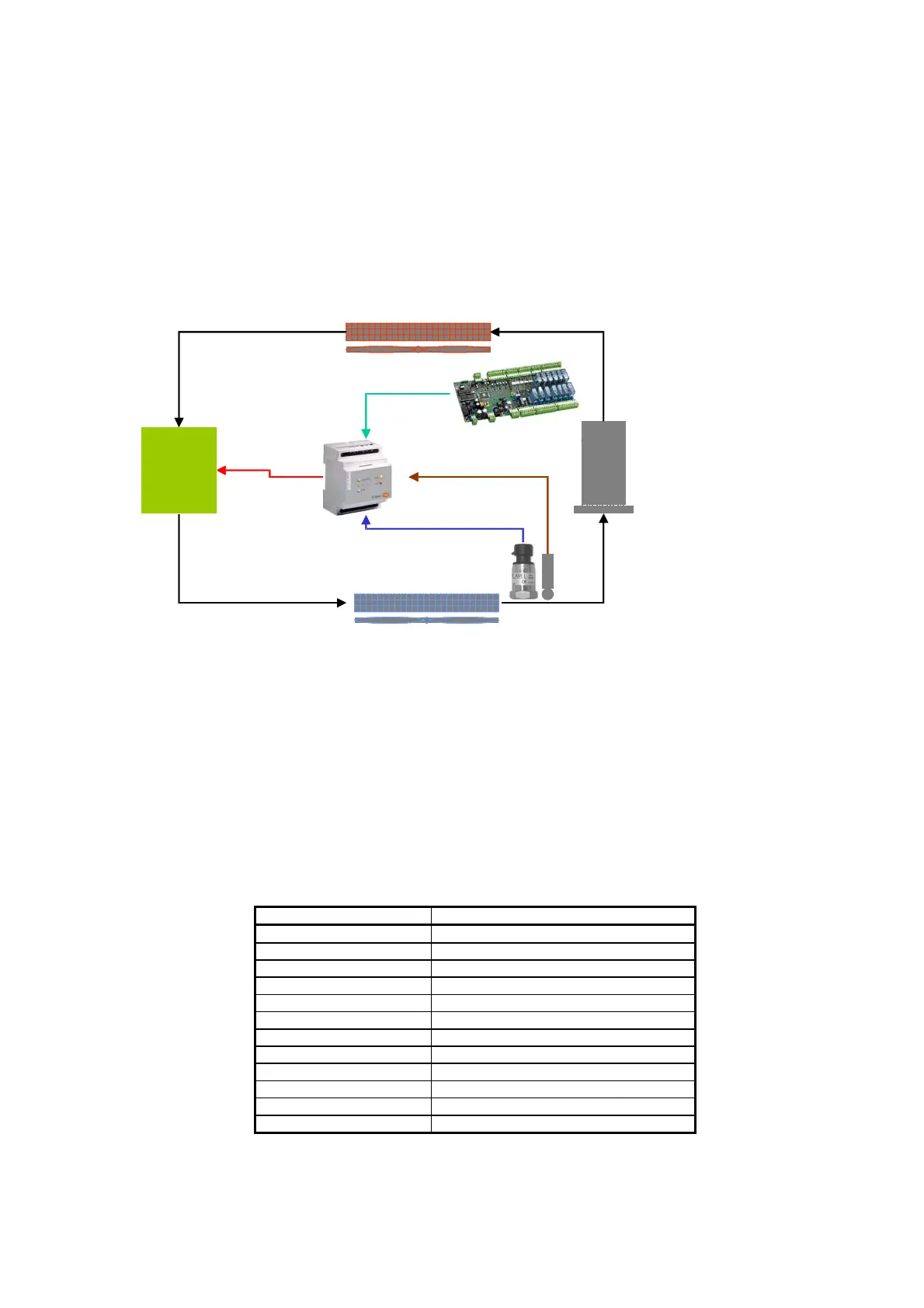

The parameters table describes the control parameters with thresholds and default values. The table below explains the meaning of the VALVE

TYPE parameter (see screens F1- F2):

PARAMETER VALUE TYPE OF CORRESPONDING VALVE

0 Alco EX5 – EX6

1 Alco EX7

2 Alco EX8

3 Sporlan SEI 0.5 - 11

4 Sporlan SEi 25

5 Sporlan SEI 50 – SHE 250

6 Danfoss ETS 50

7 Danfoss ETS 100

8 ---

9 Carel E2V**P

10 Carel E2V**A

11 Custom (other type of valve)

Condensor

EEV

Evaporator

Compressor

T probe

P probe

Motor

connection

LAN

EEV

Evaporator

T probe

P probe

Motor

connection

LAN

Loading...

Loading...