151

6.5 — Service Table

NOTE: Not all smart unloading applications use the smart

controller for discharge temperature control and protection.

The Service and LED tables allow the Installer and/or Ser-

vice Technician the ability to verify the smart controller is

functioning properly once installation is complete and the

refrigeration system is ready for service. Based on the volt-

age input signal to the smart controller, the PWM cycle and

LED status of the smart compressor can be checked per the

tables.

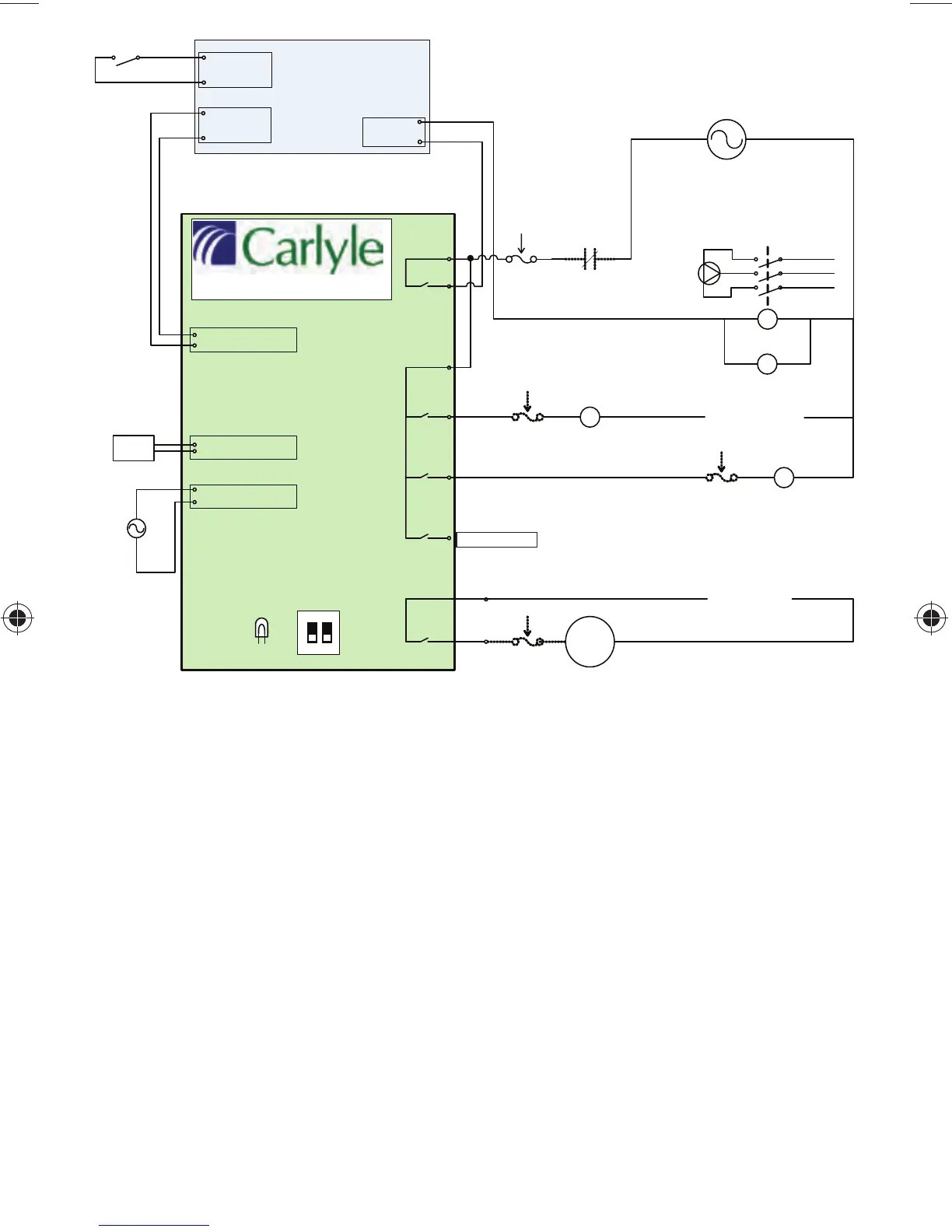

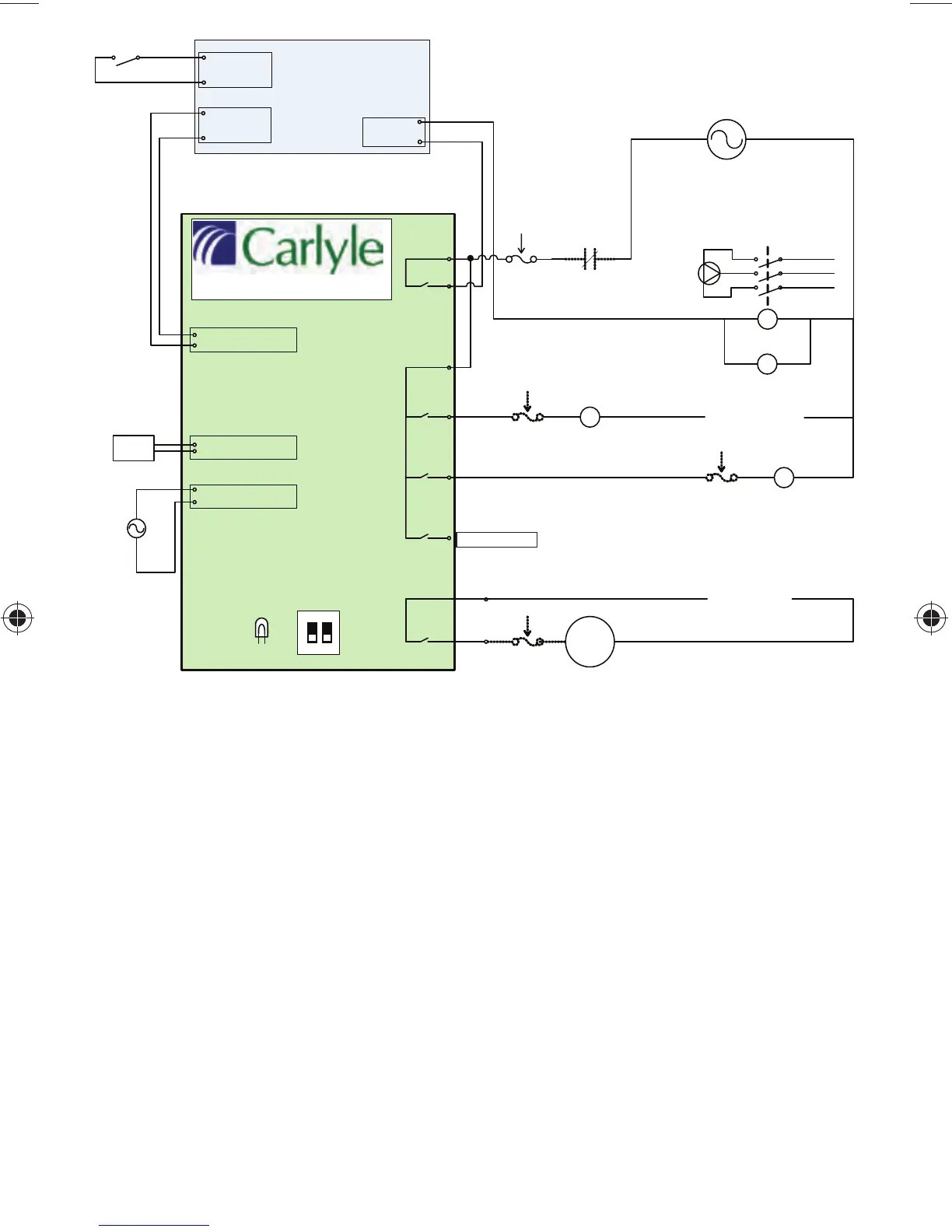

Fig. 37 — Electrical Schematic, Compressors with

1 Unloading Head or PWM Valve

M

Cylinder Head Fan

230 /460 Vac Input

Liquid

Injection

Solenoid

Unloader

Coil 1

SMART Unloading Module

T

discharge

Sensor

PT1000 D ischarge

GN D T em perature

0..10VDC Demand

GN D Signal

24 Vac

Compressor

Motor

24 Vac

Fuse

Compressor

Contactor

Protection D evices

Installed Here

115 /230 Vac Control Pow er

LN

2 am p 120 V

1 am p 240 V

Fuse

(tim e delay )

Alternate

½ amp Fuse

Alternate

½ amp Fuse

Control

Voltage

Comp

Injection

Coil 1

Coil 2

Wire

Leads

AC in

Rack

Controller

Compressor

Alarm Status

Input

Compressor

Capacity

Output (0-10 Vdc)

Compressor

Start/Stop

Isolation Relay

Com pressor Selector

ON

1 2

LED

Indicator

Isolation Relay

120 /208-230 Vac Input

Do not use Coil #2

Loading...

Loading...