60

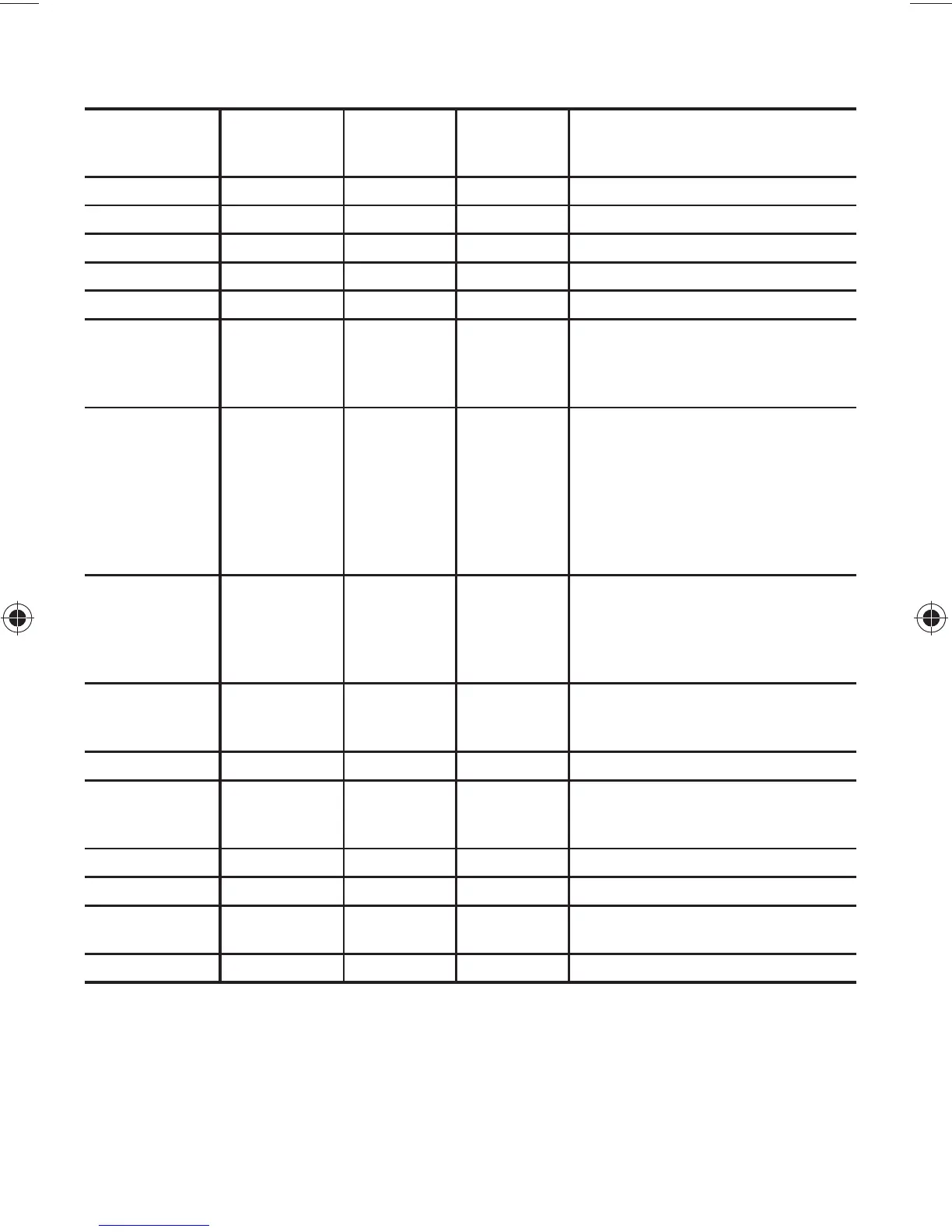

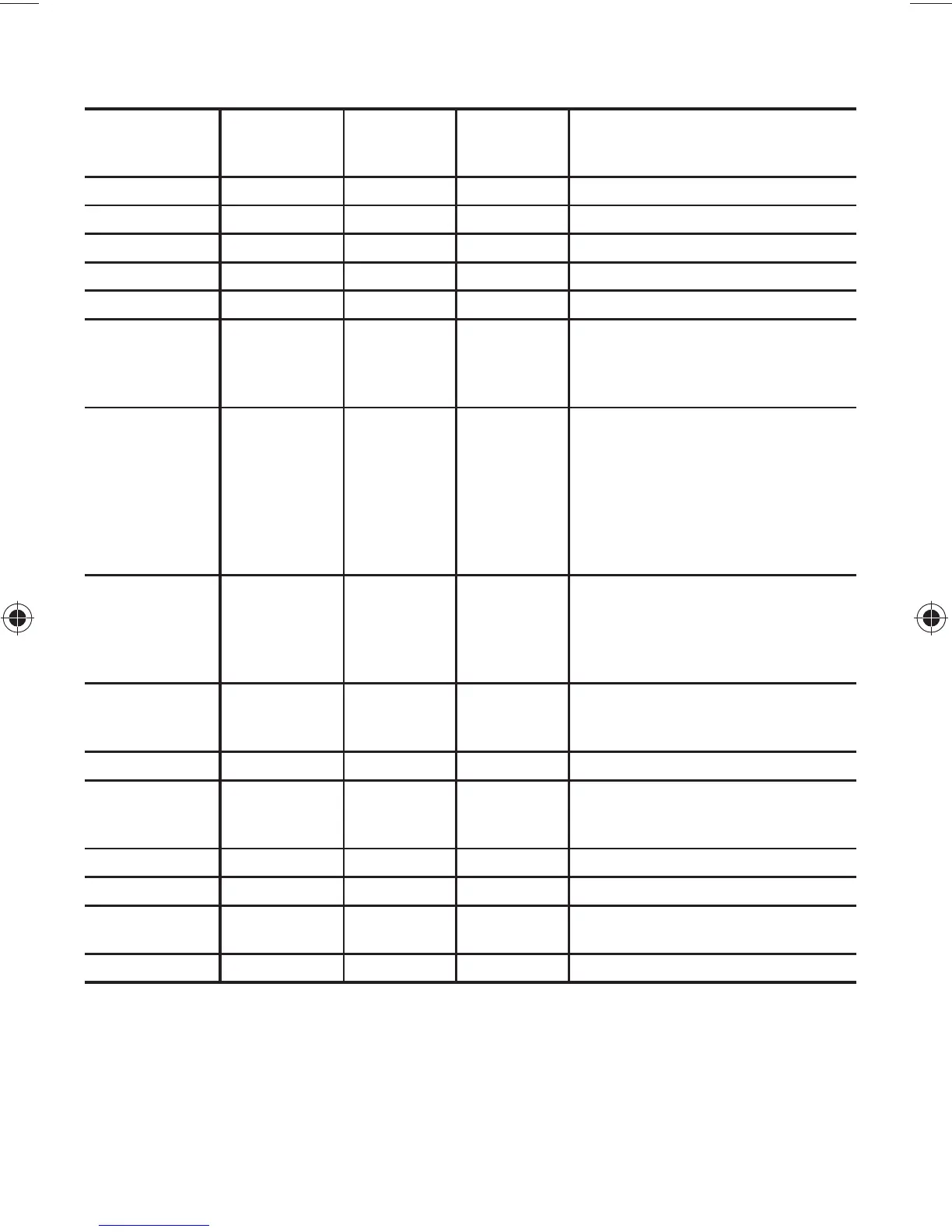

2.10 — Torque Guide - 06D and 06CC (16 to 37 Cfm)

Compressors

LEGEND

(CC) - Compound Cooling compressors only

NM - Newton meter (metric torque rating)

SAE - Society of Automotive Engineers

*See Fig. 30 page 133, for jam locations.

Torque for jam nut #3 for compressors manu-

factured after 0203J--. For compressors built

before this, jumper bar must be under jam nut

#3 or Loctite #089 applied to jam nut #2, or use

12 ft-lb.

NOTE: Bolt sizes and thread pitch: Compres-

sors are built using English unit bolts. The bolts

have no exact metric equivalents. Therefore, to

prevent possible cross-threading, loose bolts, or

damage to threaded portions of the casing,

comparable metric measurements are not

included.

SIZE

DIAMETER

(in.)

THREADS

PER INCH

TORQUE

RANGE

(FT-LB)

TORQUE

RANGE

(NM)

USAGE

1/16 Pipe 8-12 11-16 Pipe plug crankshaft

1/8 Pipe 6-10 8-14 Oil return check valve

No. 10 324-65-8 Oil pump drive segment

1/4 Pipe 20-25 27-34 Pipe plug

1/4 20 10-12 14-16 Con-rod cap screw

1/4 28 12-15 16-20

Baffle plate crankshaft

Side shield

Oil pump drive segment

Unloader

5/16 18

16-20

16-20

16-20

16-20

16-20

16-20

20-25

20-33

22-27

22-27

22-27

22-27

22-27

22-27

27-34

27-44

Cover plate bearing head

Terminal plate cap screw

Interstage outlet (CC)

Interstage manifold (CC)

Liquid injection (CC)

Suction manifold (CC)

Suction service valve

Discharge service valve

3/8 16 30-35 40-48

P.E. bearing head, crankcase

Bottom plate, crankcase

Compressor foot

Cylinder head

Motor end cover, crankcase

3/8 24-SAE 6-12 8-16

P.E. bearing head at

10-o’clock position

NOTE: Not a field usable fitting

7/16 14 55-60 75-81 Motor end cover, crankcase

7/16 20-SAE 6-12 8-16

Oil drain, on bottom cover

plate 4-cyl (18-20 Cfm) and

6-cyl 06D

1/2 20 10-12 14-16 Oil pressure regulator

1/2 1380-90 109-122 Suction service valve

5/8 11 25-30 34-4

0

Equalization spinner tube

assembly

1-1/2 1835-45 48-61 Oil level sight glass

Loading...

Loading...