154

controller, the PWM valve can easily be controlled to pro-

vide a linear incremental step change to compressor

capacity. The PWM valve is controlled in the same manner

as the unloader head on a compressor, by using a 30-second

PWM control signal from the smart controller (see Func-

tional Overview on page 138).

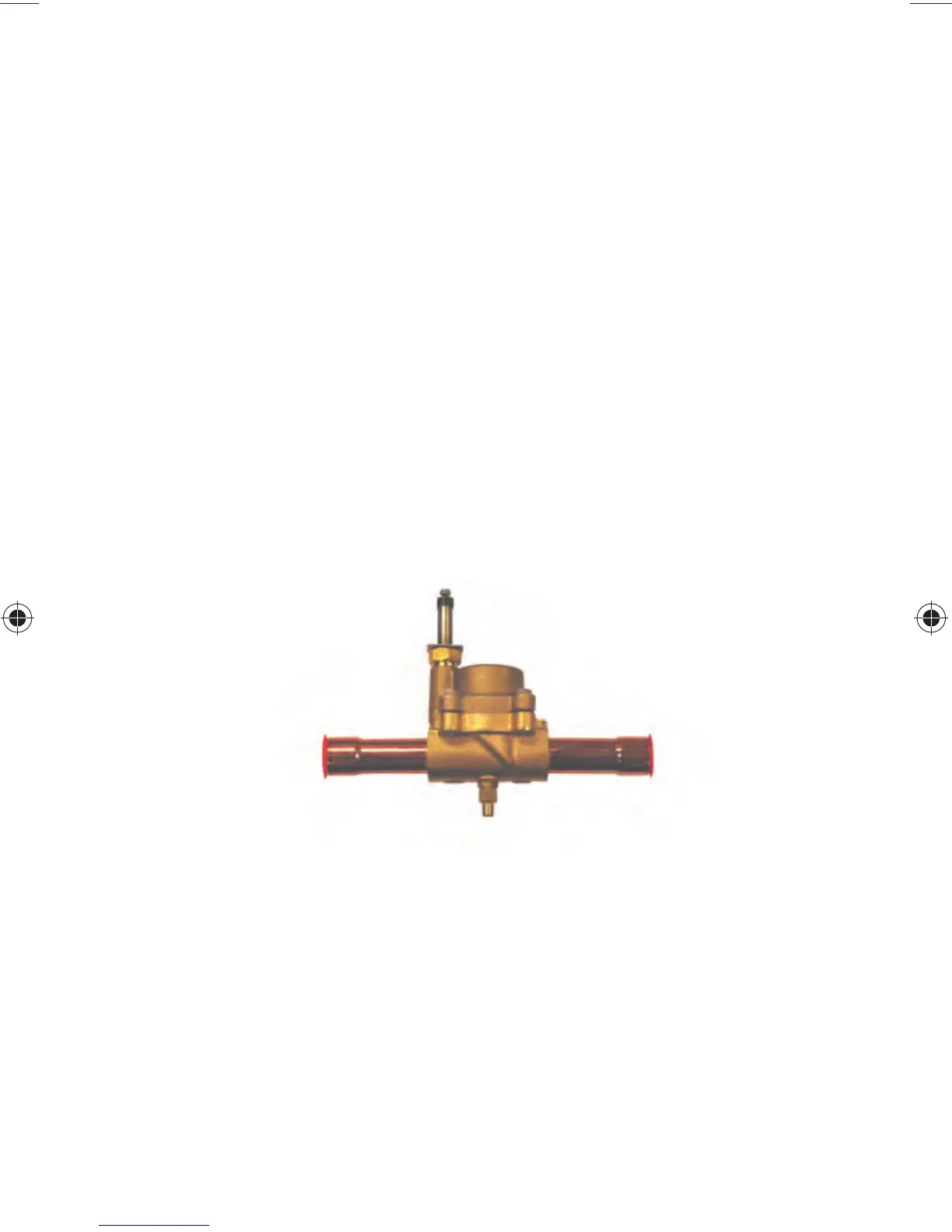

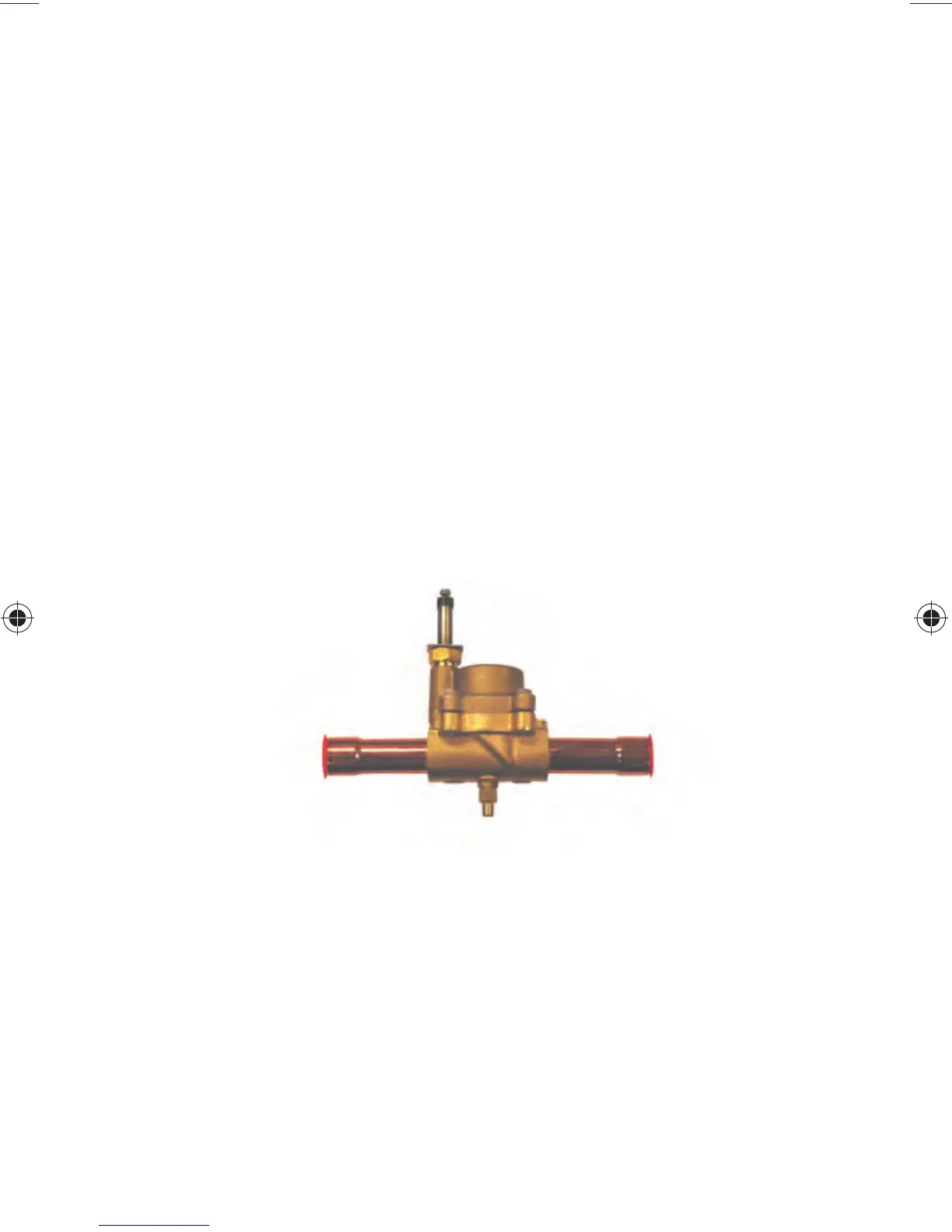

The Carlyle PWM valve (Fig. 39) is designed to work spe-

cifically with the Carlyle 06D, 06CC, and 06M compressor

models for all low, medium, and high temperature applica-

tions.

NOTE: When applying the smart controller with the PWM

valve the standard non-unloading compressor models should

be used and therefore the compressor will not have a “Y” in

the compressor model number. See the PWM Valve Dimen-

sions section for correct usage.

VALVE INSTALLATION AND OPERATION

• Inspect the PWM valve for any shipping damage and

verify the correct part number is called out on the valve.

• The PWM valve installs in the suction line of the com-

pressor. The valve should be installed along a straight

Fig. 39 — PWM Valve PN 8ADB000690 and

8ADB000907

Loading...

Loading...