156

• The PWM valve is a normally closed valve and requires

a solenoid coil to be energized to open the valve. The

PWM valve is equipped with a manual lifting stem,

when front seated, will force the valve fully open.

• Once the PWM valve is brazed in-place, the solenoid

coil can be installed. Use Carlyle solenoid coil

8ADB000688 or 8ADB000689. These coils have been

qualified and life-cycle tested with the PWM valve. The

use of any other coil is not approved by Carlyle.

• The PWM valve solenoid coil should wire back to the

Smart Control, Coil #1 position as shown in electrical

schematic Fig. 37.

• The PWM valve should not be cycled by the smart con-

troller when the compressor is not operating. Power to

the PWM valve solenoid coil should be interrupted

whenever the compressor trips off or is intentionally

taken out of service.

• The PWM valve is designed to open/close at a specified

rate to modulate compressor capacity. Upon valve clo-

sure, the compressor crankcase will pull into a vacuum.

The 06D, 06CC, and 06M compressors have all been

functionally tested and approved to operate in this

manner.

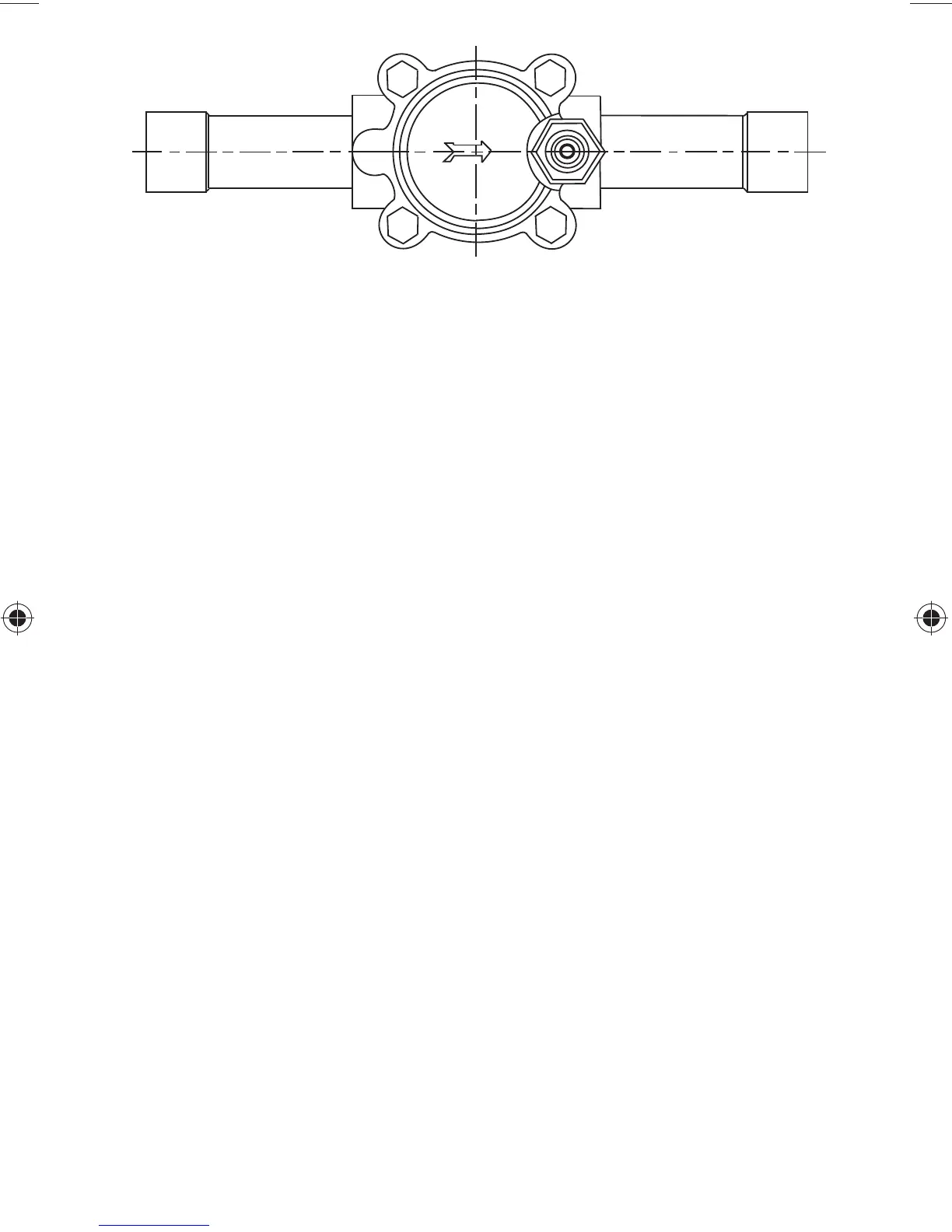

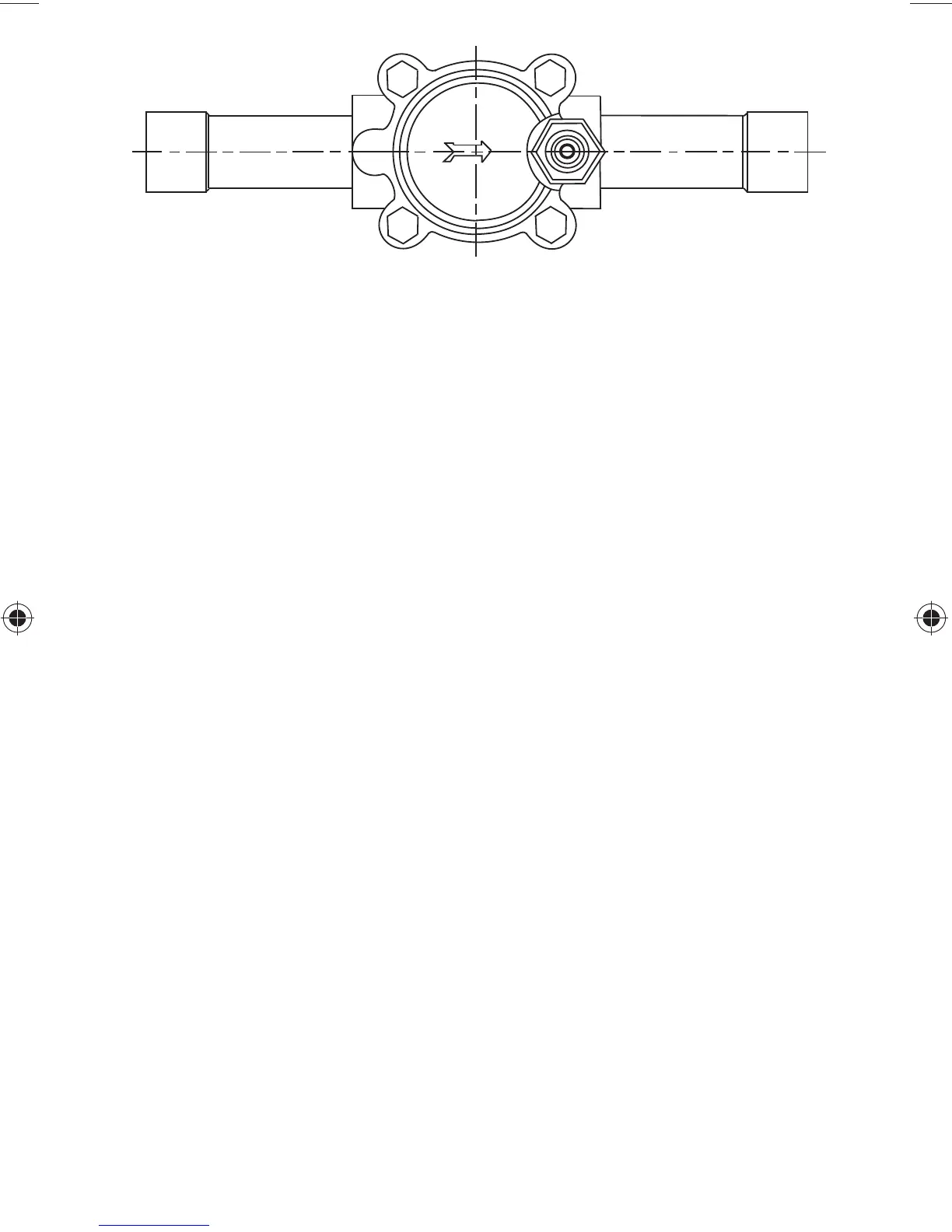

Fig. 41 — Refrigerant Flow Direction

Loading...

Loading...