110

10.6 Check Sensor Accuracy

Place the sensor in a medium of known temperature and compare that temperature to the measured reading. The

thermometer used to determine the temperature of the medium should be of laboratory quality with 0.25 °C

graduations. The sensor in question should be accurate to within 1.2 °C.

Note that the PIC5+ control module, MAINTENANCE menu, offers a temperature sensor calibration feature where

the sensor temperature can be offset. Note that only the four water temperatures can be calibrated. To use this

feature, place the sensor @ 0°C or other known temperature. Read the raw temperature and calculate offset

based on the reading seen in the TEMP_CAL menu. Enter and execute the offset, which cannot exceed ± 1.2°C.

The sensors are immersed directly in the refrigerant or water circuits. When installing a new sensor, apply a pipe

sealant or thread sealant to the sensor threads.

An additional thermistor, factory installed in the bottom of the cooler barrel, is displayed as Evap Refrig Liquid

Temp on the TEMPERATURES display screen. This thermistor provides additional protection against a loss of

water flow.

DUAL TEMPERATURE SENSORS

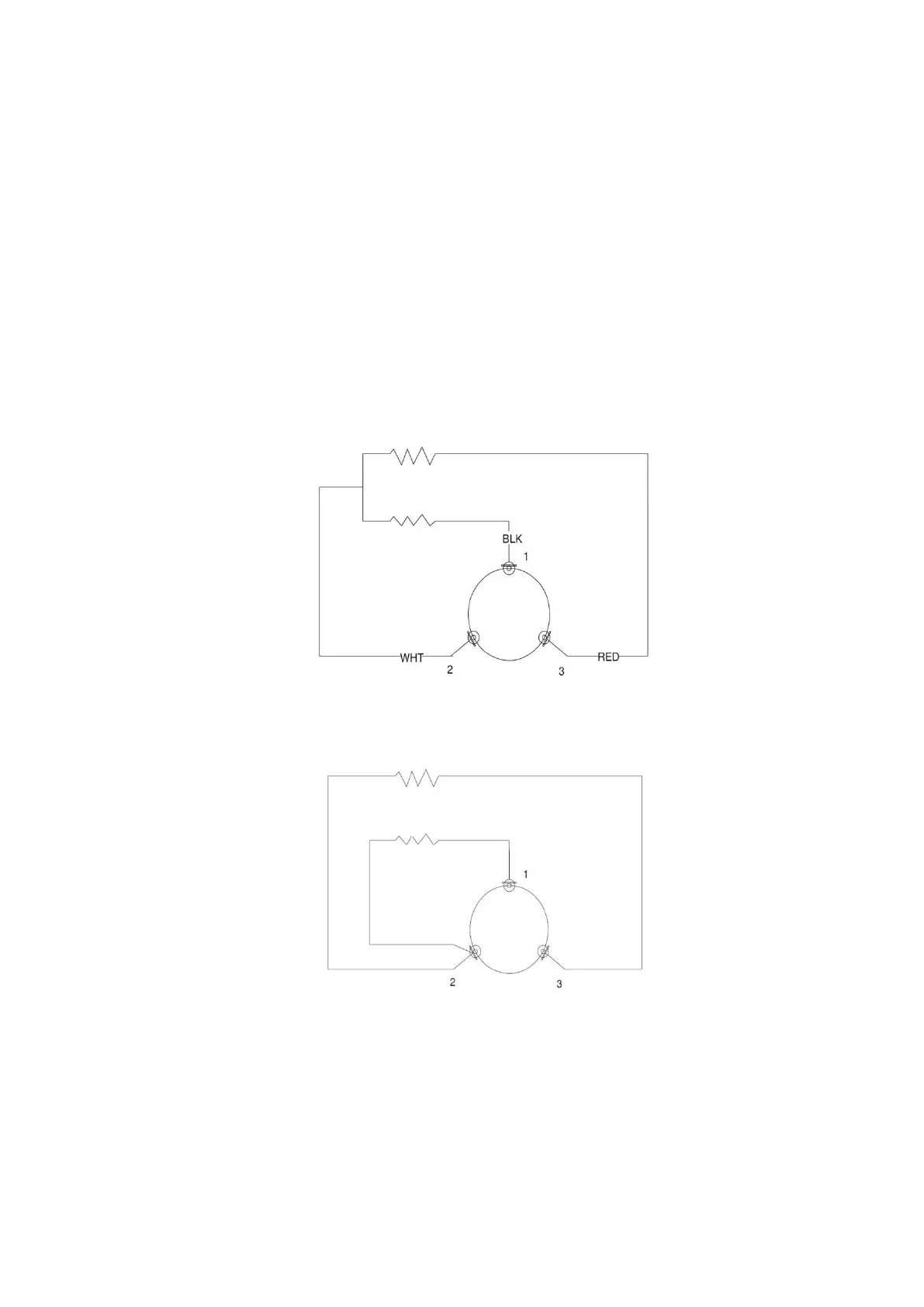

For servicing convenience, there are 2 redundant sensors each on the bearing and motor temperature sensors. If

one of the sensors is damaged, the other can be used by simply moving a wire. The number 2 terminal in the

sensor terminal box is the common line. To use the second sensor, move the wire from the number 1 position to

the number 3 position. See fig 59 and 60.

Fig 59 – 1

st

stage / 2

nd

stage Bearing Temperature (RT39C / RT40C) sensor wiring

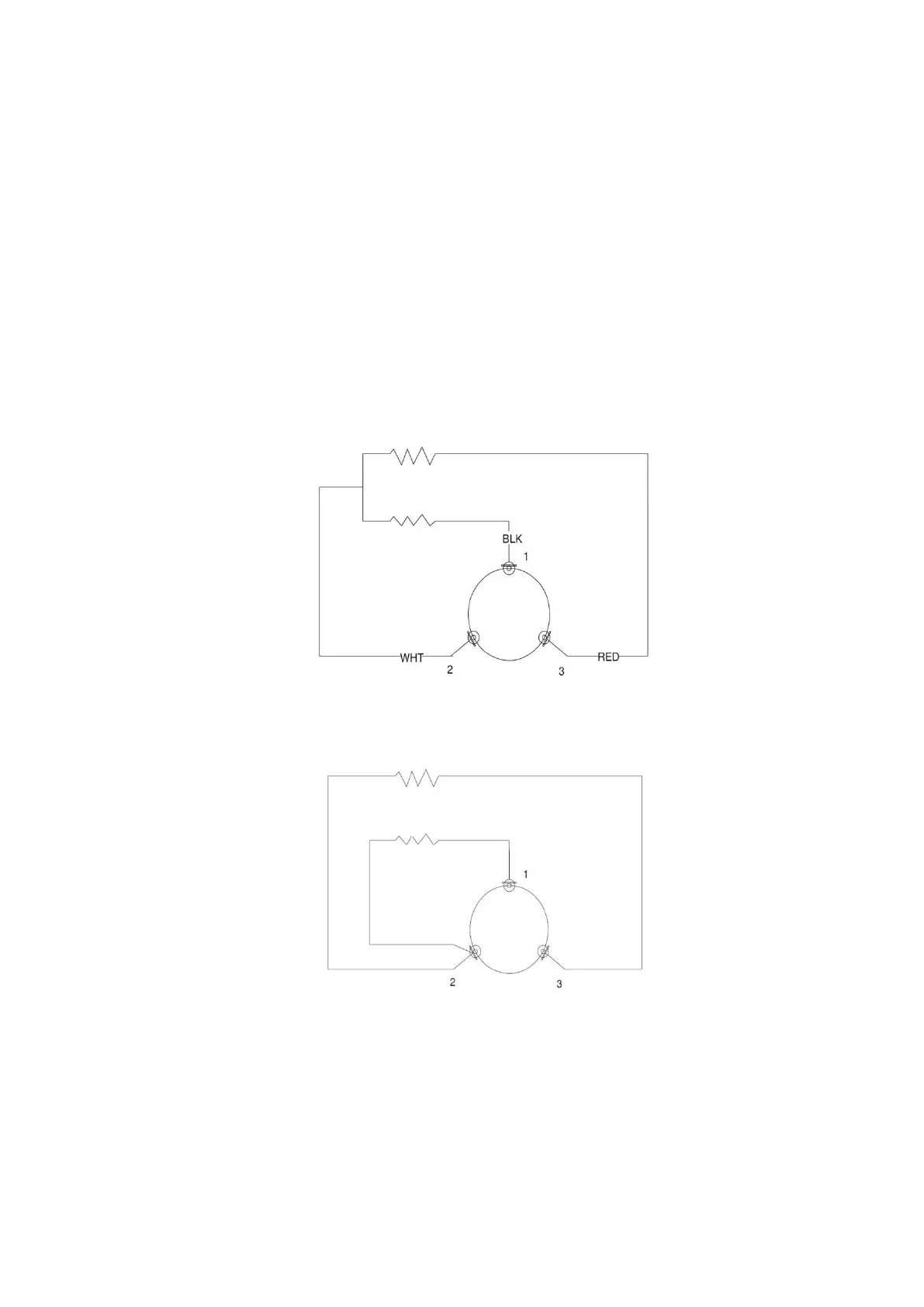

Fig 60 – Winding Temperature (RT31C) sensor wiring

Loading...

Loading...