46

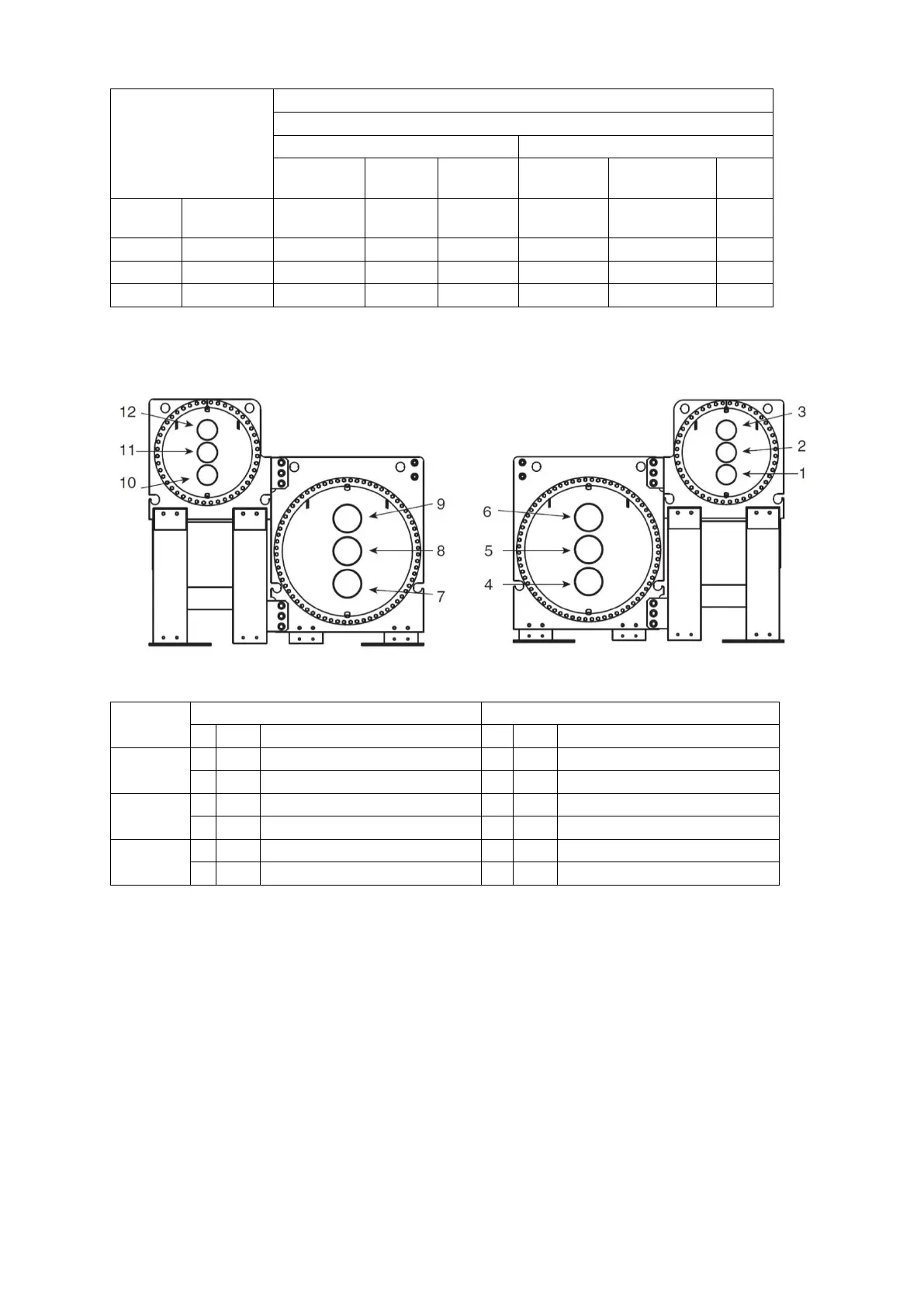

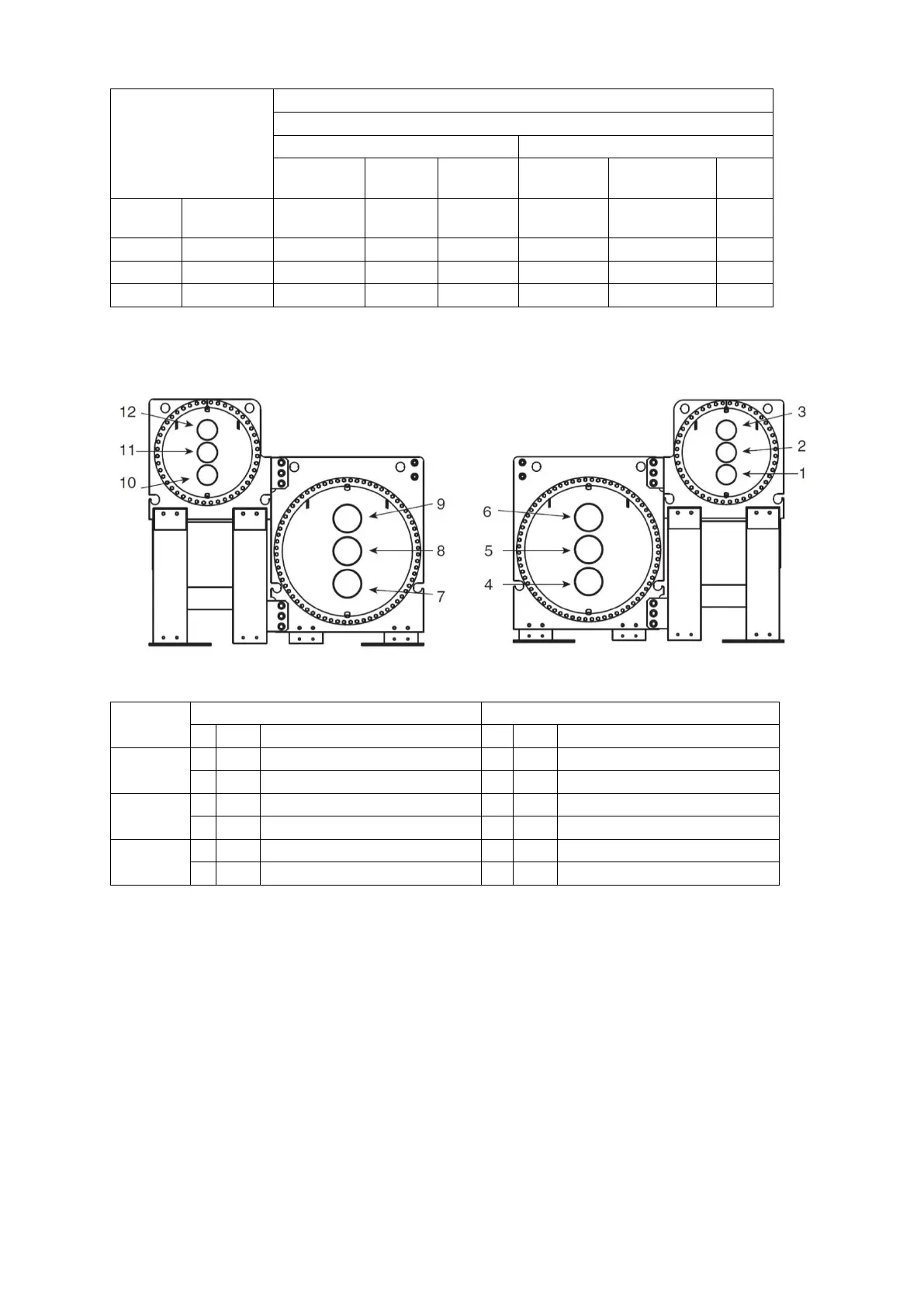

Heat exchanger

frame size

Table 12 – 19DV nozzle size

* : Refer to certified drawings

Fig. 22 - “Standard waterboxes

and nozzle arrangements”

3.5.1 Install water piping to heat exchanger

Install piping using job data, piping drawings, and procedures outlined below. A typical piping installation is

shown in Fig. 23.

CAUTION: Factory-supplied insulation is not flammable but can be damaged by welding sparks and open flame.

Protect insulation with a wet canvas cover.

CAUTION: To prevent damage to sensors, remove evaporator and condenser water temperature sensors before

welding connecting piping to water nozzles. Replace sensors after welding is complete.

Loading...

Loading...