30

2.6.5 Pressure transducers

Pressure transducers are used to measure and control the pressures in the unit. These electronic sensors deliver

0 to 5 VDC. The transducers can be calibrated through the controller. The pressure transducers are connected to

the IOBs.

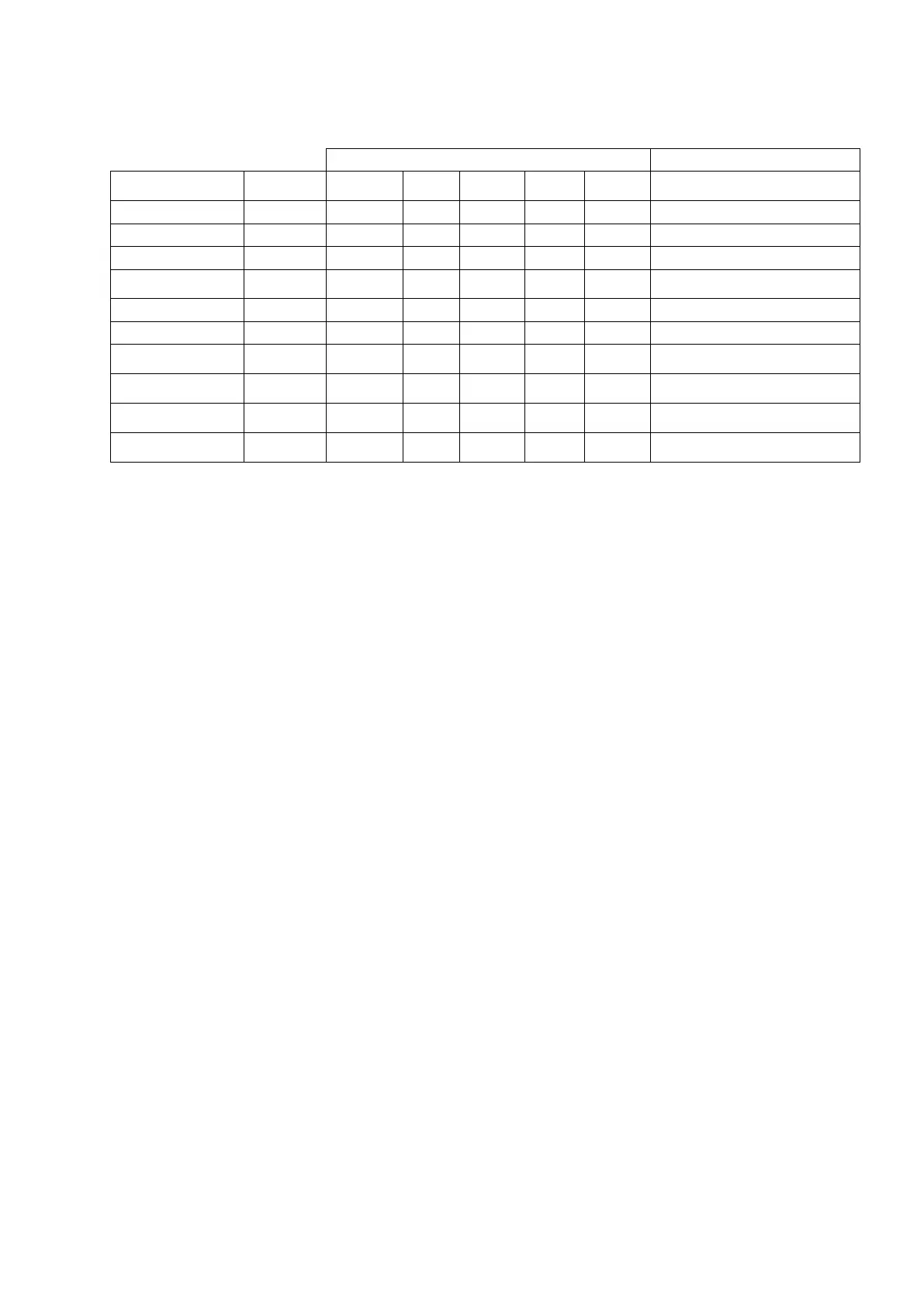

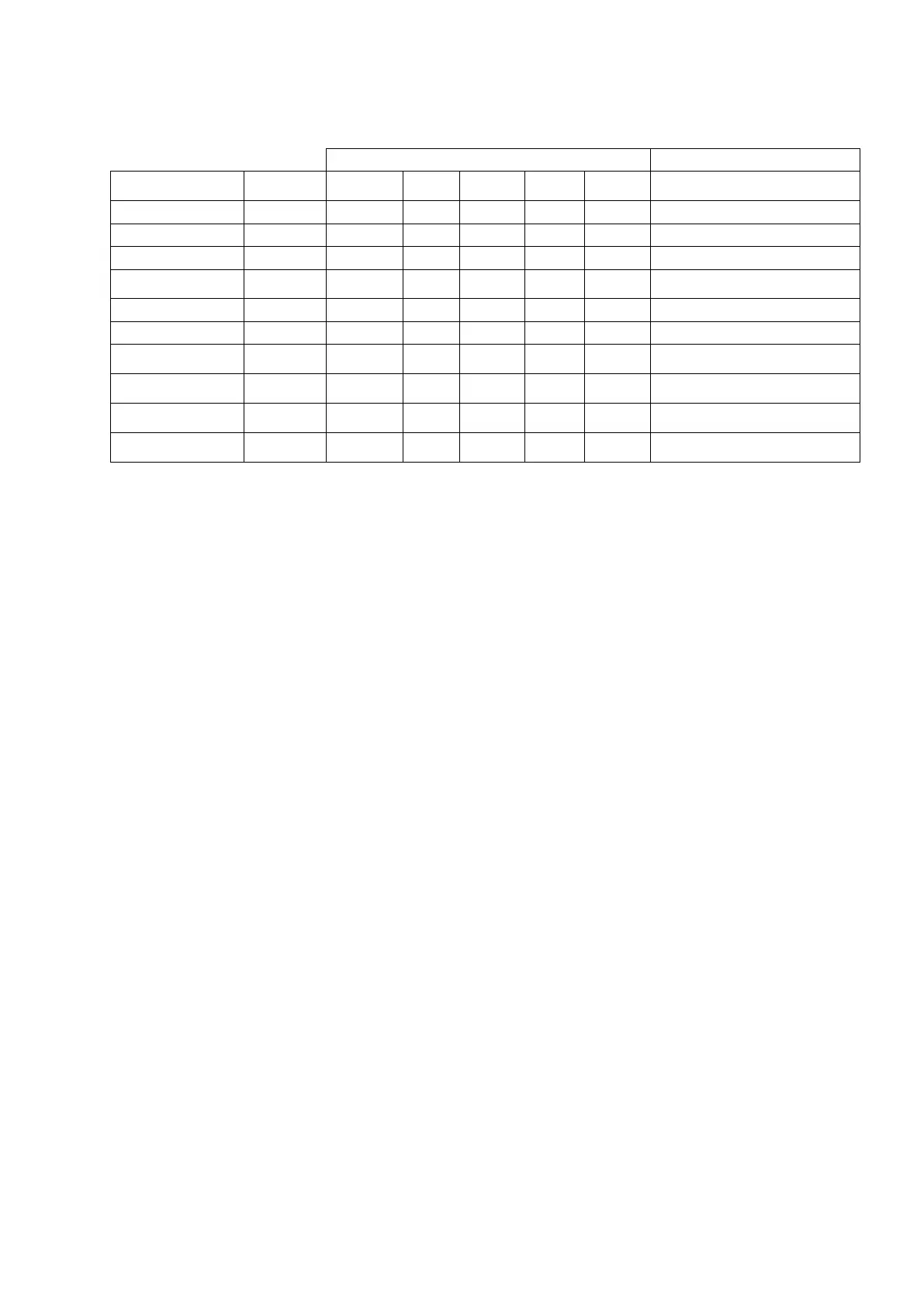

Wiring information (see chiller wiring diagram)

5VDC – low refr. Pressure range

5VDC – low refr. Pressure range

5VDC – low refr. Pressure range

5VDC – low refr. Pressure range

5VDC – low refr. Pressure range

5VDC – low refr. Pressure range

5VDC – low refr. Pressure range

Entering Evap water

pressure

5VDC – water side pressure range

Leaving Evap water

pressure

5VDC – water side pressure range

Entering Cond water

pressure

5VDC – water side pressure range

Leaving Cond water

pressure

5VDC – water side pressure range

Table 1b – Pressure sensors

3. INSTALLATION

3.1 Introduction

The 19DV machines are factory assembled, wired, leak tested and electrically tested. Installation (not by Carrier)

consists primarily of establishing water and electrical services to the machine. The rigging, installation, field wiring,

field piping, and insulation of waterbox covers are the responsibility of the contractor and/or customer.

3.2 Step 1 – Receive the machine

3.2.1 – Inspect the product delivered

CAUTION: Do not open any valves or loosen any connections. The standard 19DV machine is shipped with a full

refrigerant charge. Some machines may be shipped with a nitrogen holding charge as an option. Damage to

machine may result.

1. Inspect for shipping damage while machine is still on shipping conveyance. If machine appears to be

damaged or has been torn loose from its anchorage, have it examined by transportation inspectors before

removal. Forward claim papers directly to transportation company. Manufacturer is not responsible for any

damage incurred in transit.

2. Check all items against shipping list. Immediately notify the nearest Carrier representative if any item is

missing.

3. To prevent loss or damage (standard EN 378-2 11.22 k, annex A and B), leave all parts in original packages

until beginning installation. All openings are closed with covers or plugs to prevent dirt and debris from

entering machine components during shipping. A full operating inhibitor charge is placed in the

lubrication assembly before shipment. from the factory. Do not open lube assembly valves until unit is fully

charged with refrigerant.

3.2.2 – Identify machine

Confirm that the unit received is the one ordered. Compare the name plate data with the order. The unit name

plate must include the following information:

-- Service number

-- Serial number

-- Model number

-- Variant

-- Year of manufacture and test date

-- CE marking

Loading...

Loading...