76

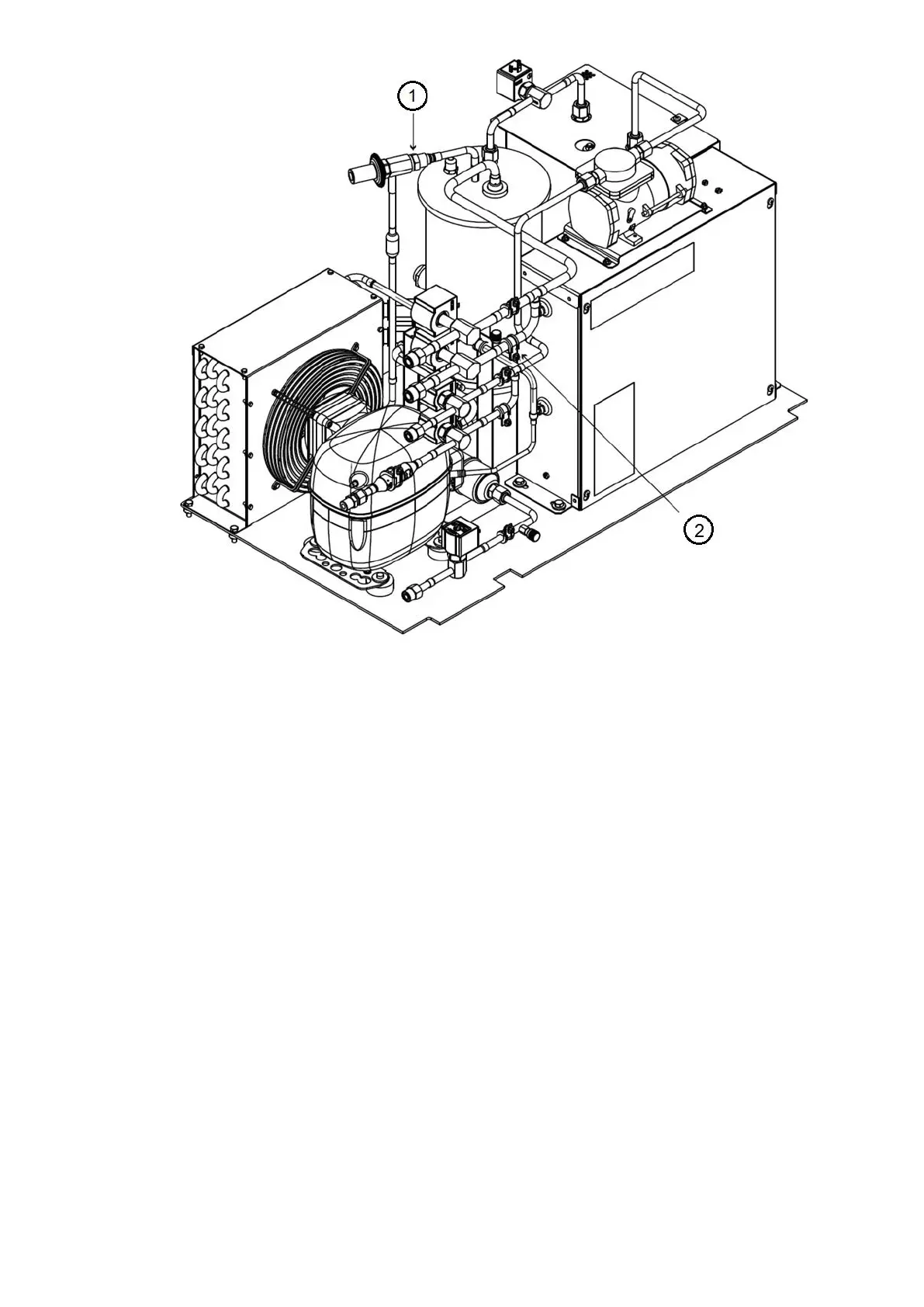

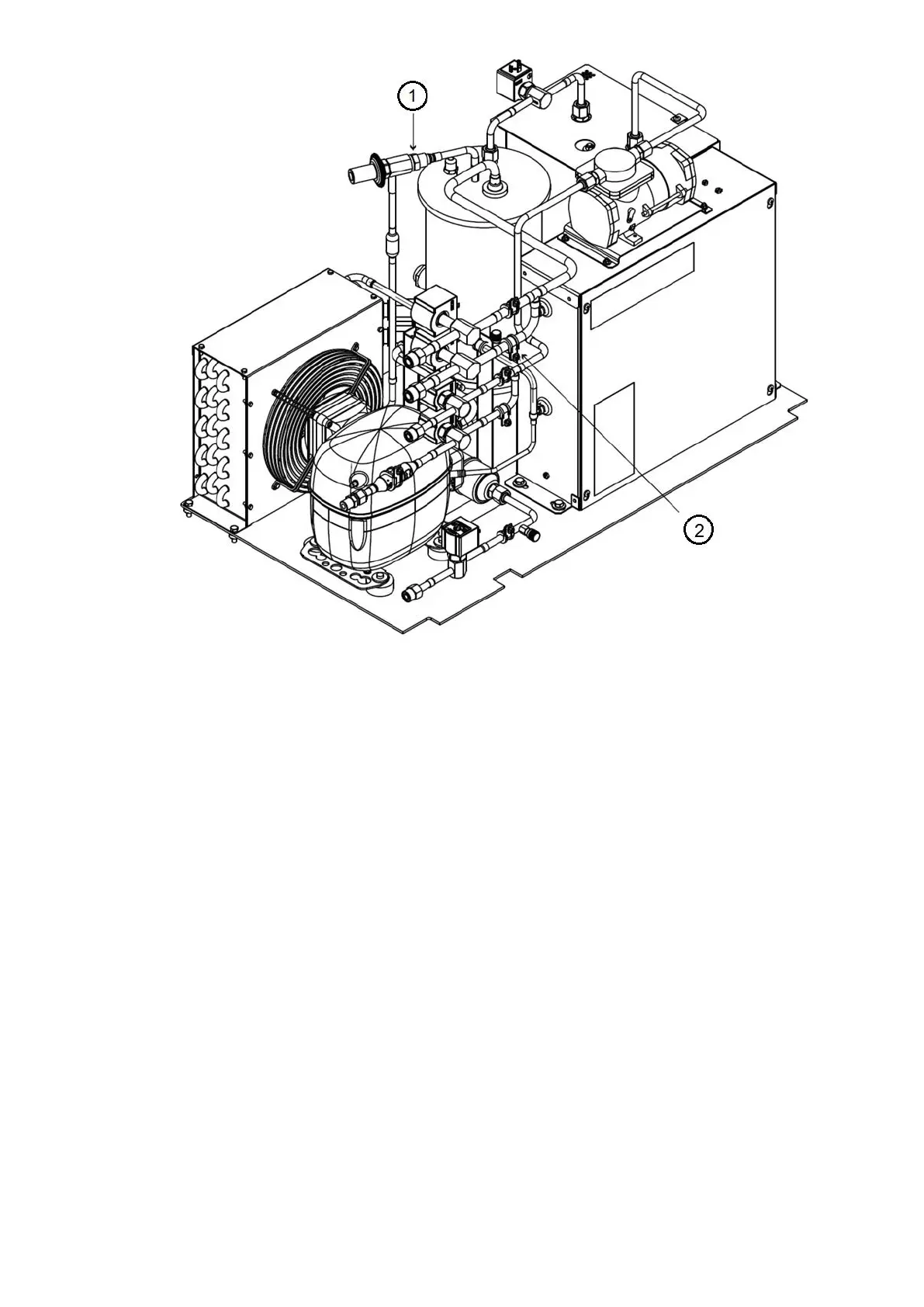

1 : Expansion valve

2 : Suction Schrader valve

Note : Clockwise rotation of expansion valve adjustment screw increases the pressure setting and counterclockwise rotation

decreases pressure setting.

Fig 42 – purge system setting

5.5 Checking the Installation

Use the following instructions to verify the condition of the installation:

1. Turn off, lock out, and tag the input power to the drive.

2. Wait a minimum of 5 minutes for the DC bus to discharge.

3. All wiring should be installed in conformance with the applicable local, national, and international codes.

4. Remove any debris, such as metal shavings from the enclosure.

5. Check that there is adequate clearance around the machine.

6. Verify that the wiring to the terminal strip and the power terminals is correct and that no external voltage

potential are connected to any of the inputs.

7. Verify that all of the VFD power module circuit board connectors are fully engaged and taped in place.

8. Check that the wire size is within terminal specifications and that the wires are tightened properly and

adequately supported.

9. Check that specified branch circuit protection is installed and correctly rated.

10. Check that the incoming power is within ±10% of chiller nameplate voltage.

11. Verify that a properly sized ground wire installed and a suitable earth ground is used. Check for and eliminate

any grounds between the power leads. Verify that all ground leads are unbroken to the power supply. Only a wye

secondary power supply transformer with solidly grounded neutral is acceptable as a power supply to this chiller.

5.6 Check Lubrication Circuit system

Please check condenser float chamber liquid level. If lubrication system works properly, the liquid level sensor

should indicate ON.

Loading...

Loading...