72

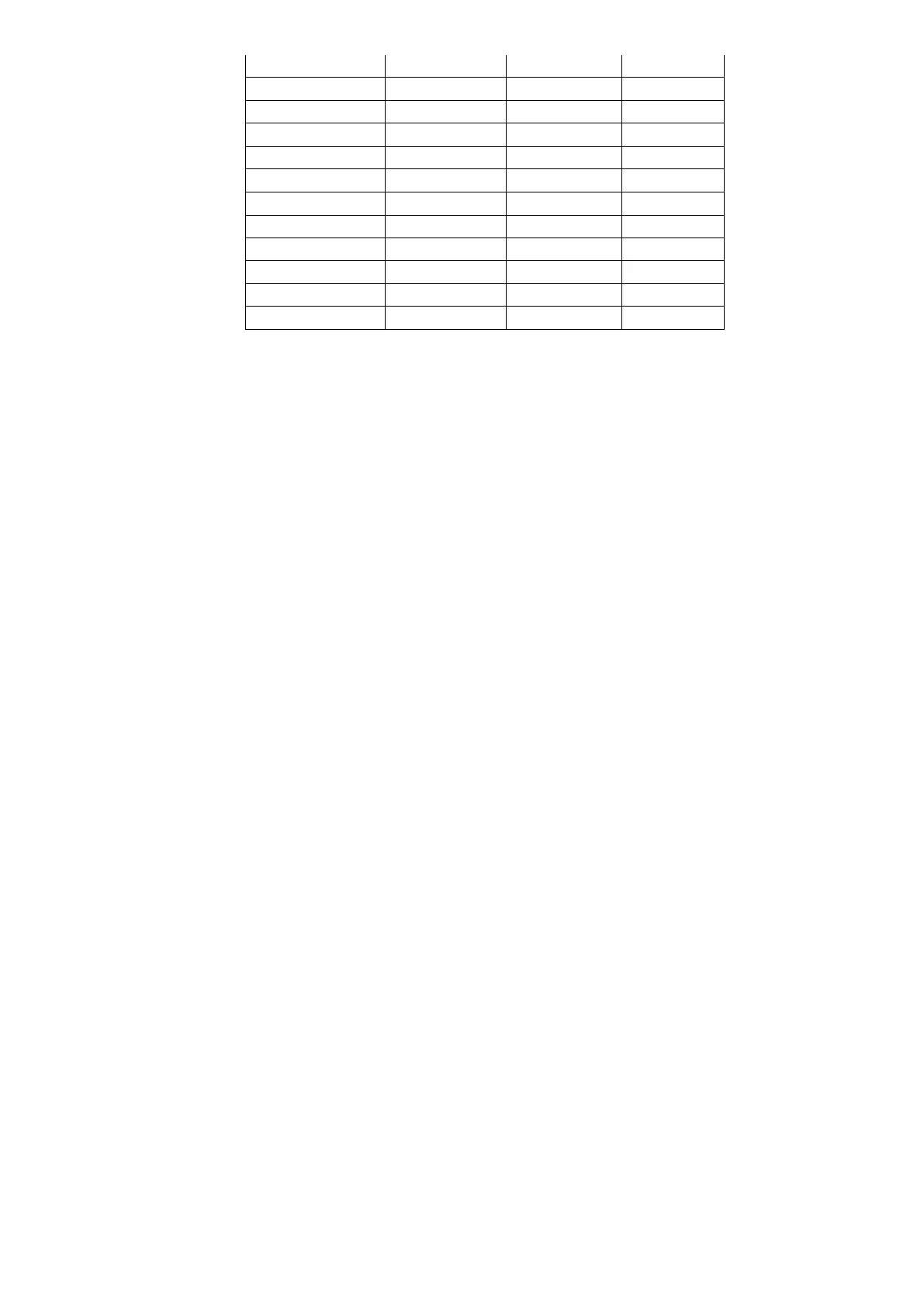

Table 17 – R1233zd(E) Pressure / Temperature

5.1.7 Standing Vacuum Test

When performing the standing vacuum test or chiller dehydration, use a manometer or a wet bulb indicator. Dial

gages cannot indicate the small amount of acceptable leakage during a short period of time.

1. Attach an absolute pressure manometer or wet bulb indicator to the chiller.

2. Evacuate the vessel to at least 0.06 kPa [abs], using a vacuum pump.

3. Shut off pump valve to hold the vacuum and record the manometer or wet bulb indicator reading.

4. If the pressure rise is less than 56 Pa within 8 hours, the chiller is sufficiently tight.

If the pressure rise exceeds above criteria, re-pressurize the vessel and conduct leak test and repair the leak

point.

5.1.8- Chiller dehydration

Dehydration is recommended if the chiller has been open for a considerable period of time, if the chiller is known

to contain moisture, or if there has been a complete loss of chiller holding charge or refrigerant pressure.

CAUTION: Do not start or megohm-test the compressor motor or any other pump motor, even for a rotation check,

if the chiller is under dehydration vacuum. Insulation breakdown and severe damage may result.

WARNING: Power to the motor and VFD must be disconnected by an isolation switch before placing the machine

under a vacuum. To be safe, isolate input power before evacuating the chiller if you are not sure if there are live

leads to the hermetic motor.

Dehydration can be done at room temperatures. Using a cold trap (Fig. 41) may substantially reduce the time

required to complete the dehydration and is recommended should the unit be exposed to liquid moisture. The

higher the room temperature, the faster dehydration takes place. At low room temperatures, a very deep vacuum

is required for boiling off any moisture. If the ambient temperatures are low, contact a qualified service

representative for the dehydration techniques required.

Loading...

Loading...