34

dissolved oxygen must be present. Dissolved iron < 5

mg/l with dissolved oxygen < 5 mg/l.

• Dissolved silicon: silicon is an acid element of water and

can also lead to corrosion risks. Content < 1mg/l.

• Water hardness: > 0.5 mmol/l. Values between 1 and 2.5

can be recommended. This will facilitate scale deposit

that can limit corrosion of copper. Values that are too

high can cause piping blockage over time. A total

alkalimetric titre (TAC) below 100 is desirable.

• Dissolved oxygen: Any sudden change in water oxygenation

conditions must be avoided. It is as detrimental to

deoxygenate the water by mixing it with inert gas as it

is to over-oxygenate it by mixing it with pure oxygen.

The disturbance of the oxygenation conditions encourages

destabilisation of copper hydroxides and enlargement

of particles.

• Electric conductivity 10-600µS/cm

• pH: Ideal case pH neutral at 20-25 °C - 7 < pH < 8

If the water circuit must be emptied for longer than one

month, the complete circuit must be placed under nitrogen

charge to avoid any risk of corrosion by differential aeration.

ATTENTION: Filling, completing and draining the water

circuit charge must be done by qualied personnel, using the

air purges and materials that are suitable for the products.

Charging and removing heat exchange uids should be done

with devices that must be included on the water circuit by

the installer. Never use the unit heat exchangers to add heat

exchange uid.

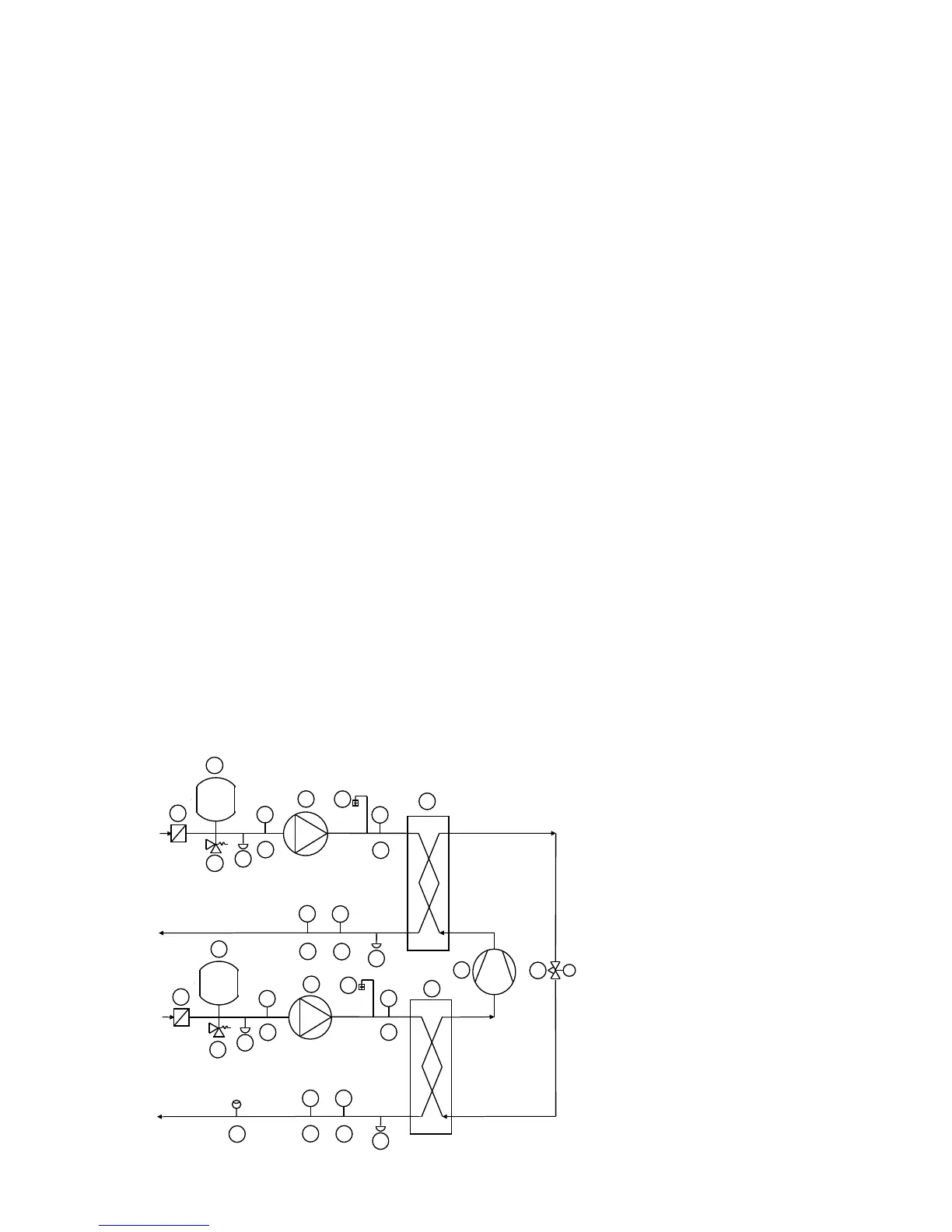

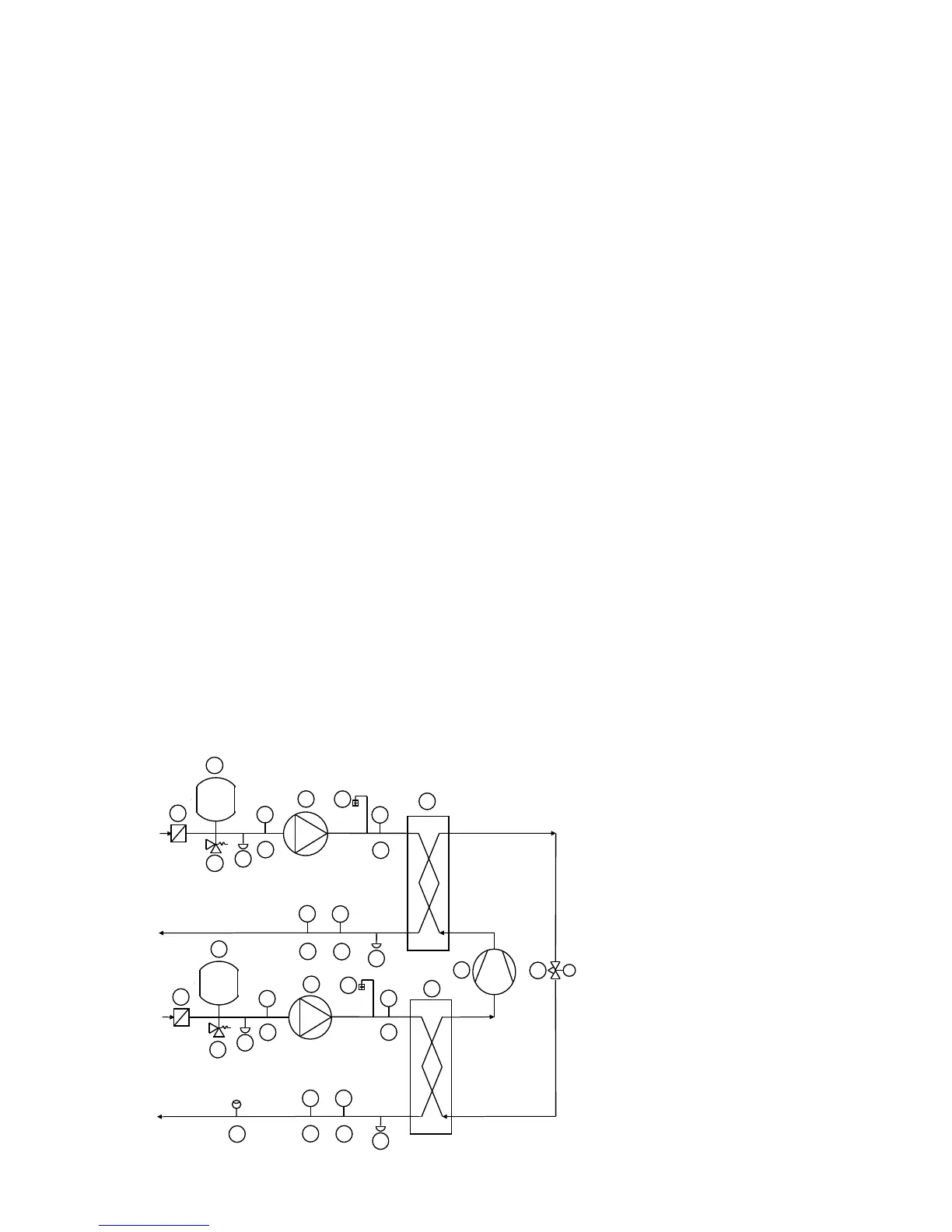

9.2 - Water connections

The diagram below illustrates a typical hydronic installation.

When the hydronic circuit is charged, use the air vents to

evacuate any residual air pockets.

not installed, the plate heat exchanger can quickly become

contaminated at the rst start-up, as it takes on the lter

function, and correct unit operation is affected (reduced

water ow due to increased pressure drop).

Damage due to absence of safety valve, expansion tank or

screen lter (i.e. without option 293 or 293A) is not covered

by the warranty.

Before the system start-up verify that the water circuits are

connected to the appropriate heat exchangers (e.g. no reversal

between evaporator and condenser).

Do not introduce any signicant static or dynamic pressure

into the heat exchange circuit (with regard to the design

operating pressures).

Before any start-up verify that the heat exchange uid is

compatible with the materials and the water circuit coating.

If additives or other uids than those recommended by Carrier

are used, ensure that the uids are not considered as a gas, and

that they belong to class 2, as dened in directive 2014/68/EU.

Carrier recommendations on heat exchange uids:

• No NH

4+

ammonium ions in the water, they are very

detrimental for copper. This is one of the most important

factors for the operating life of copper piping. A content

of several tenths of mg/l will badly corrode the copper

over time (the plate heat exchangers used for these units

have brazed copper joints).

• Cl

-

Chloride ions are detrimental for copper with a risk

of perforations by corrosion by puncture. If possible

keep below 125 mg/l.

• SO

4

2-

sulphate ions can cause perforating corrosion, if

their content is above 30 mg/l.

• No uoride ions (<0.1 mg/l).

• No Fe

2+

and Fe

3+

ions with non negligible levels of

Typical water piping diagram, 61WG/30WG/30WGA units with hydronic modules

Components of unit and hydronic module

1 Victaulicscreenlter(option293or293Aonly)

2 Expansiontank(option293or293Aonly)

3 Safetyvalve(option293or293Aonly)

4 Water pump

5 Air vent

6 Water drain valve

7/8 Entering/leavingpressuresensor

9/10Entering/leavingtemperatureprobe

12 Flow switch 61WG option 272 (sizes 020-045

only)

13 Compressor

14 Evaporator

15 Condenser

16 Expansion device

NOTE: Units without hydronic

module include a ow switch.

2

6

15

10

9

8

5

1

3

4

7

6

14

9

8

5

1

2

4

PT

PT

TT

TT

PT

PT TT

13

16

TT

12

3

7

10

6

6

Unit water inlet

Condenser water loop (61WG/30WG)

Unit water outlet

Unit water inlet

Unit water outlet

Evaporator water loop (61WG/30WG/30WGA)

Loading...

Loading...