How to calibrate temperature sensor on Carrier RTU Open controller?

- KkristenperezAug 5, 2025

To correct the temperature reading on your Carrier RTU Open controller, use the controller's calibration function to offset the temperature reading.

How to calibrate temperature sensor on Carrier RTU Open controller?

To correct the temperature reading on your Carrier RTU Open controller, use the controller's calibration function to offset the temperature reading.

What to do if Carrier controller shows battery low voltage?

If the battery voltage of your Carrier controller is below 2.9 volts, replace the battery.

How to check thermistor accuracy in Carrier RTU Open?

To check the thermistor accuracy on your Carrier controller, connect a meter to the thermistor leads to get a resistance value. Then, convert this resistance to a temperature using Table 2.

Warning about electrical shock hazards during service and wiring.

Guidance on installing sensors and accessories for the RTU Open controller.

Instructions for installing various analog sensors like SAT, OAT, and SPT.

Configuration of temperature and humidity setpoints for occupied/unoccupied periods.

Unit configuration parameters for the RTU Open controller.

Configuration of various input functions for the RTU Open controller.

Control logic for cooling operation.

Operation and wiring of the outdoor enthalpy sensor for economizer cooling.

Control logic and wiring for differential enthalpy sensing.

Inspection of accessories and wiring.

Using service test to verify component operation.

Manual control of the fan output for testing.

Testing individual compressor stages for proper operation.

Testing individual heat stages for proper operation.

Testing the dehumidification relay and modes.

Manual control of the power exhaust output.

Manual control of the economizer damper position.

Testing the VFD supply fan speed output.

Configuration of temperature and humidity setpoints.

Unit configuration parameters.

Method for determining unit occupancy.

Configuration of unit type and number of cooling stages.

Configuration for economizer existence and fan control type.

Description of occupancy control methods.

Configuration and operation of the indoor supply fan.

Control logic for cooling operation.

Fan control types: Single, Two Speed, Variable Speed.

Conditions required for economizer to operate.

Economizer damper positioning based on conditions.

Using enthalpy sensors for economizer cooling suitability.

Control of indoor air quality using CO2 sensors.

Control of power exhaust fan based on occupancy or damper position.

Purging the space with outdoor air before occupancy.

Control logic for heating operation.

Maintaining indoor air quality with optional sensors.

Operation of dehumidification with Humidi-Mizer option.

Utilizing optimal start for efficient heating/cooling initiation.

Configuring compressor safety input for equipment protection.

General troubleshooting steps for the RTU Open controller.

More alarm information and status.

Menus for performing various service tests on unit components.

Accessing and viewing controller alarms.

Settings for performing various diagnostic tests on unit components.

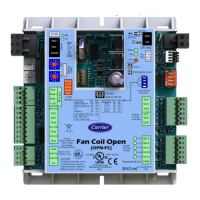

| Brand | Carrier |

|---|---|

| Model | RTU Open |

| Category | Controller |

| Language | English |

Loading...

Loading...