62-11863 5-16

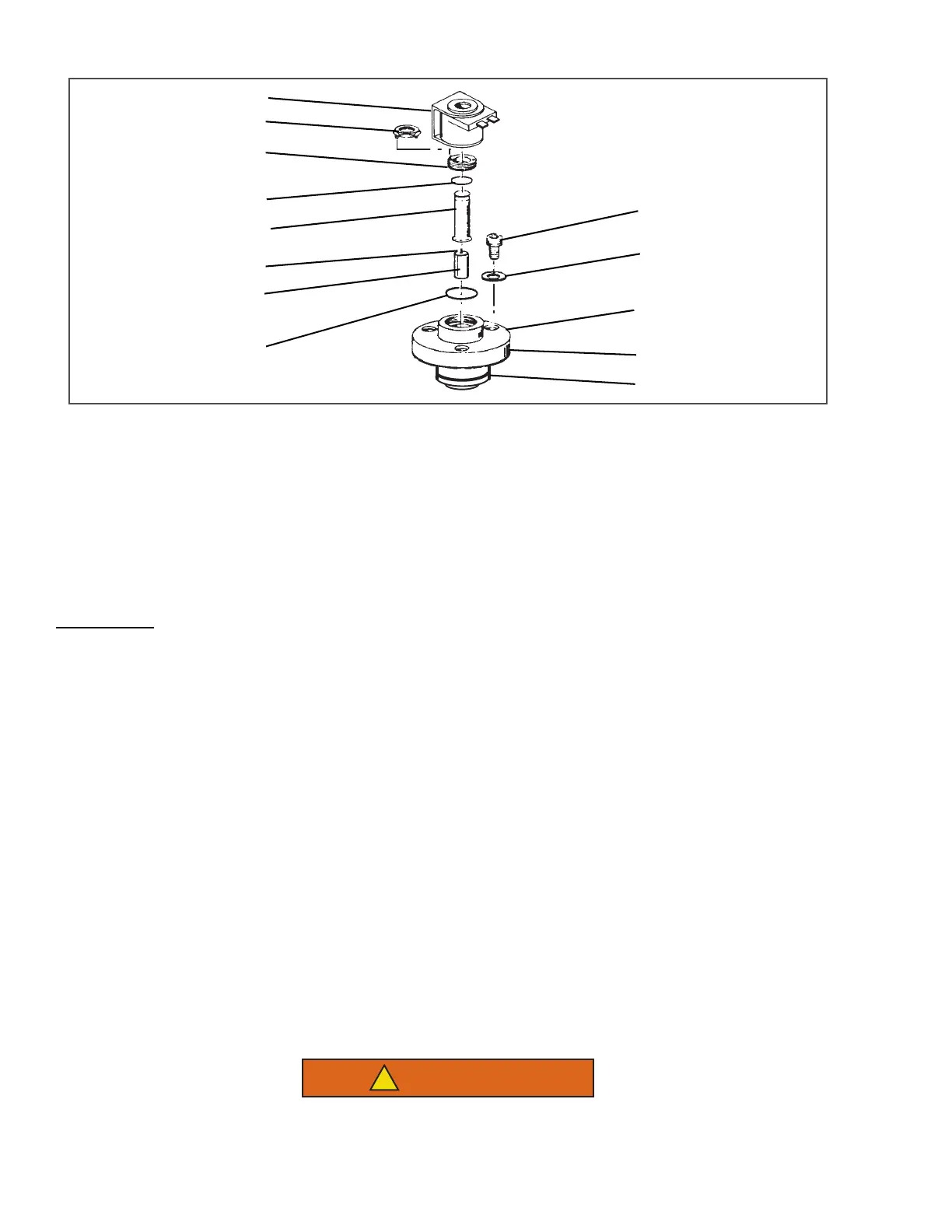

Figure 5.9 Unloader Solenoid Valve

1. Coil Assembly

2. Installation/removal tool

3. Enclosing tube Collar

4. O-ring

5. Enclosing tube

6. Plunger spring

7. Plunger assembly

8. Gasket

9. Valve body

10. Gasket

11. Bolt

12. Gasket, bolt

13. Piston ring

- - - - -

5.11 CHECKING AND REPLACING FILTER DRIER

Two Methods

:

To Check Filter Drier

Check for a restricted or plugged filter drier by feeling the liquid line inlet and outlet connections of the drier car-

tridge. If the outlet side feels cooler than the inlet side, then the filter drier should be changed.

To Replace Filter Drier

a. Pump down the unit per Section 5.4.

b. Remove bracket, then replace drier.

c. Check refrigerant level (refer to Section 5.7.2).

5.12 CHECKING AND REPLACING HIGH PRESSURE CUTOUT SWITCHES (HP1 OR HP2)

5.12.1 Removing High Pressure Switch

The High Pressure switch is located near the top of the compressor.

a. Pump down the unit (refer to Section 5.4). Frontseat both suction and discharge service valves to isolate

compressor (HP) or discharge and receiver valve.

b. Slowly release compressor pressure through the service valve gauge ports.

c. Disconnect wiring and remove.

5.12.2 Checking High Pressure Switch

Do not use a nitrogen cylinder without a pressure regulator. Cylinder pressure is approxi-

mately 2350 psig (159.9 bar). Do not use oxygen in or near a refrigerant system as an explosion

may occur. (See Figure 5.10)

Loading...

Loading...