40

Staging of compressors is shown in Tables 38-45.

EDT Low Override

There is an override if EDT drops too low based on an alert

limit that will lock out cooling. If the supply air/evaporator dis-

charge temperature (EDT) falls below the alert limit (Configu-

ration

ALLM

SA.L.O) cooling will be inhibited. There is a

20-minute hold off on starting cooling again once the follow-

ing statement is true: EDT minus (Run Status

COOL

SUMZ

ADD.R) has risen above SA.L.O. The variable

ADD.R is one of the SumZ cooling algorithm control variables

dedicated mainly for multi-stage control.

Cooling Control and the Economizer

TRIM For SUMZ = NO

ECON

E.TRM = NO

Cooling control will first check for the availability of the econ-

omizer. If free cooling can be used, then the control will first

attempt to use the free cooling.

If no mechanical cooling is active, and the economizer is active,

the economizer will first attempt to control to a cooling control

point of either the supply air setpoint high (SA.HI) or supply air

setpoint low (SA.LO) plus any reset applied, depending on

whether High Cool or Low Cool mode is in effect, respectively.

If one stage of mechanical cooling is on, and the economizer is

active, then the economizer will attempt to control to 53°F.

Also If HVAC mode = LOW COOL, the second stage of me-

chanical cooling will be locked out.

If the setpoint cannot be satisfied or the economizer is not ac-

tive, then cooling will be brought on one stage at a time when

the evaporator discharge temperature (EDT) is greater the

1.5°F above the current cooling control point. A start-up time

delay of 10 minutes and steady state delay after a compressor is

energized of 5 minutes is enforced.

If both circuits of mechanical cooling are running, then the

economizer will attempt to control to 48°F. If the economizer is

active and the outside-air temperature (OAT) is less than the

cooling control point + 0.5°F, the compressors will be locked

off. When mechanical cooling is on, the control may also use

the economizer to trim the leaving-air temperature to prevent

unnecessary cycles of the compressor stages.

See “ECONOMIZER INTEGRATION WITH MECHANI-

CAL COOLING” on page 50 for more information on the

holding off of mechanical cooling as well as the economizer

control point.

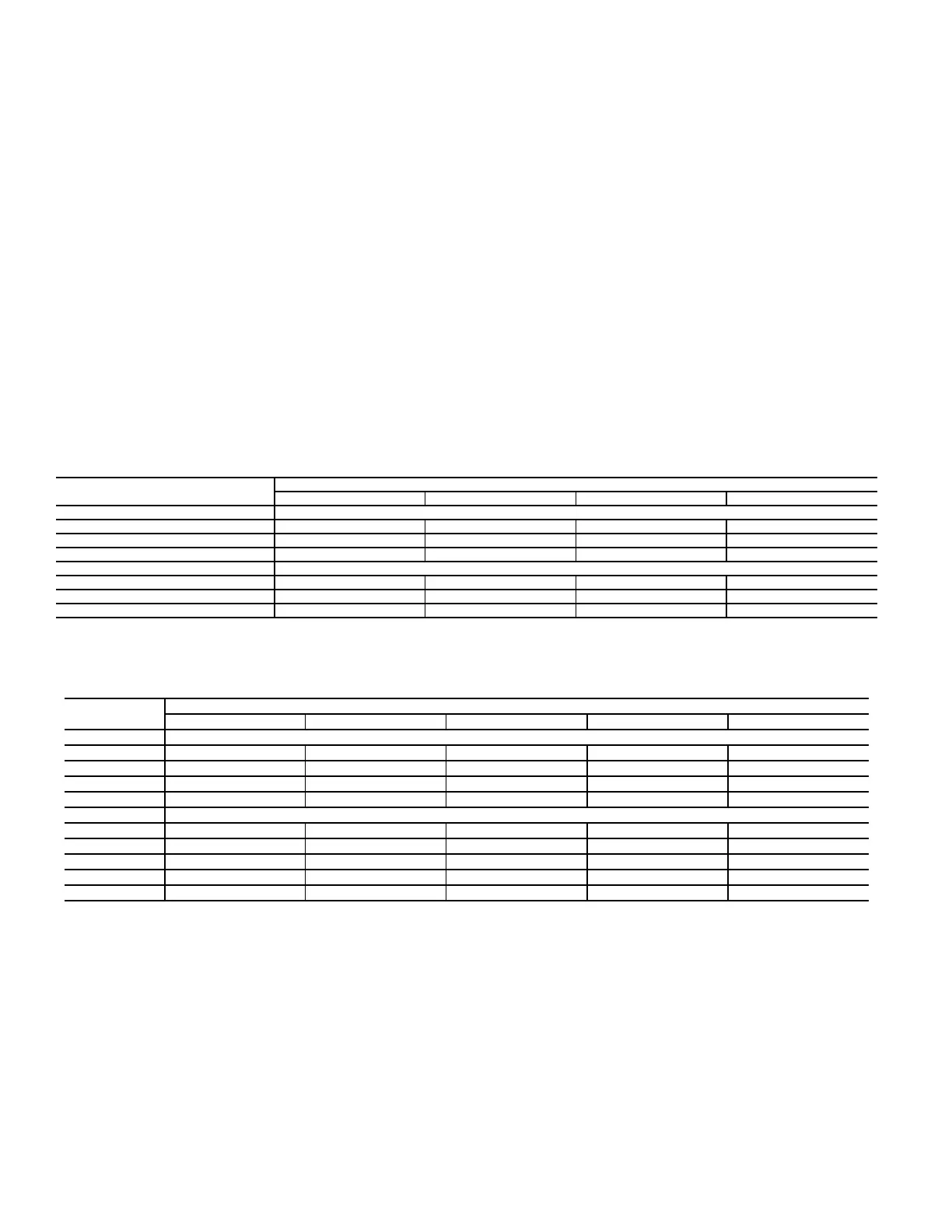

Table 38 — Capacity Control Staging Options —

48/50A020-027 Units VAV and Adaptive CV/SAV Staging Sequence with Variable Capacity Compressor

*On units with optional digital scroll compressor, compressor B1 modu-

lates from minimum to maximum capacity to provide increased stages.

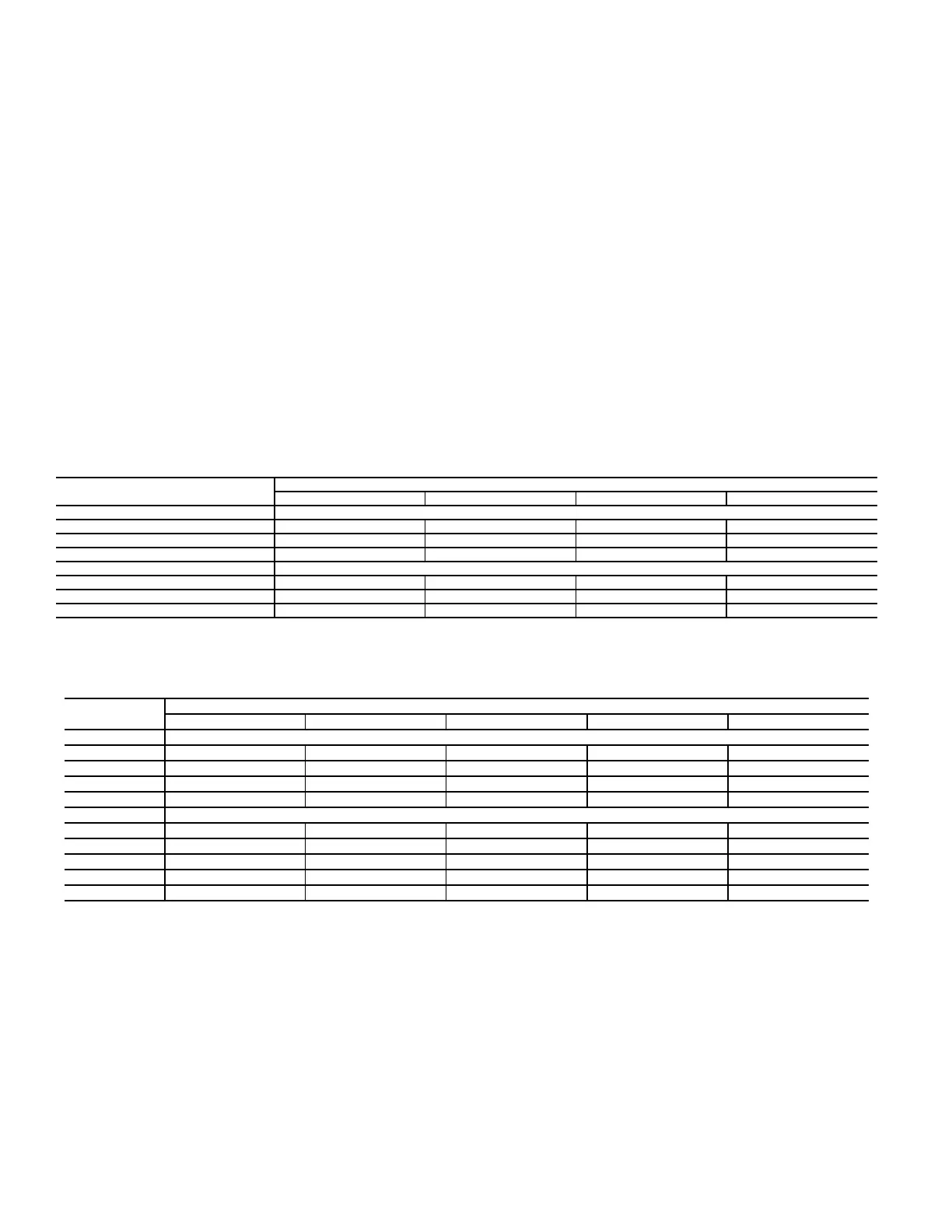

Table 39 — 48/50A030-060 Units VAV and Adaptive CV/SAV Staging Sequence with

Variable Capacity Compressor

*With minimum load valve ON.

STAGE

0123

COMP Compressor Status

A1 OFF OFF ON ON

A2 OFF OFF OFF ON

B1* OFFONONON

UNIT Unit Capacity 48/50A

020 0% 20 to 40% 50 to 70% 80 to 100%

025 0% 17 to 33% 50 to 66% 83 to 100%

027 0% 17 to 33% 50 to 66% 83 to 100%

STAGE

SEQUENCE 1

01234

COMP Compressor Status

A1* OFFONONONON

A2 OFF OFF ON ON ON

B1 OFF OFF OFF ON ON

B2 OFF OFF OFF OFF ON

UNIT Unit Capacity 48/50A

030 0% 12.5% to 25% 37.5% to 50% 62.5% to 75% 87.5% to 100%

035 0% 9.8% to 19.6% 29.4% to 29.4% 59.8% to 69.6% 90.2% to 100%

040 0% 12.5% to 25% 37.5% to 50% 62.5% to 75% 87.5% to 100%

050 0% 12.5% to 25% 37.5% to 50% 62.5% to 75% 87.5% to 100%

060 0% 12.5% to 25% 37.5% to 50% 62.5% to 75% 87.5% to 100%

Loading...

Loading...