CHAPTER 6 - MAINTENANCE AND ADJUSTMENTS

6-3

6-34551NA Issued 8-04 Bur

TRACKS

MAINTENANCE SPECIFICATIONS

Clean .......................................................................... Periodically and when the machine has been working in mud

Check tension............................................................................................................................................Periodically

Check steel pad screw torques.............................Every 250 hours (after the first 50 hours during the run-in period)

Check the rubber track pads (optional)...........................................................................Every 10 hours or every day

IMPORTANT: If the tracks are too tight, they wear

quickly. If tracks are not tight enough, they wear

quickly and the links can catch on the sprocket wheel

or slide off the idler wheel or the sprocket wheel.

Clean the tracks after work.

IMPORTANT: For rubber tracks (Optional), avoid

pivoting on the spot as this could cause the tracks to

wear out quickly and could also cause jamming of

stones, rocks, etc. Avoid working in an area full of

rock rubble or debris, pieces of reinforced concrete or

striated plates.

CLEANING

When the machine has been working in mud, a

reduction in temperature can cause the mud to

solidify.

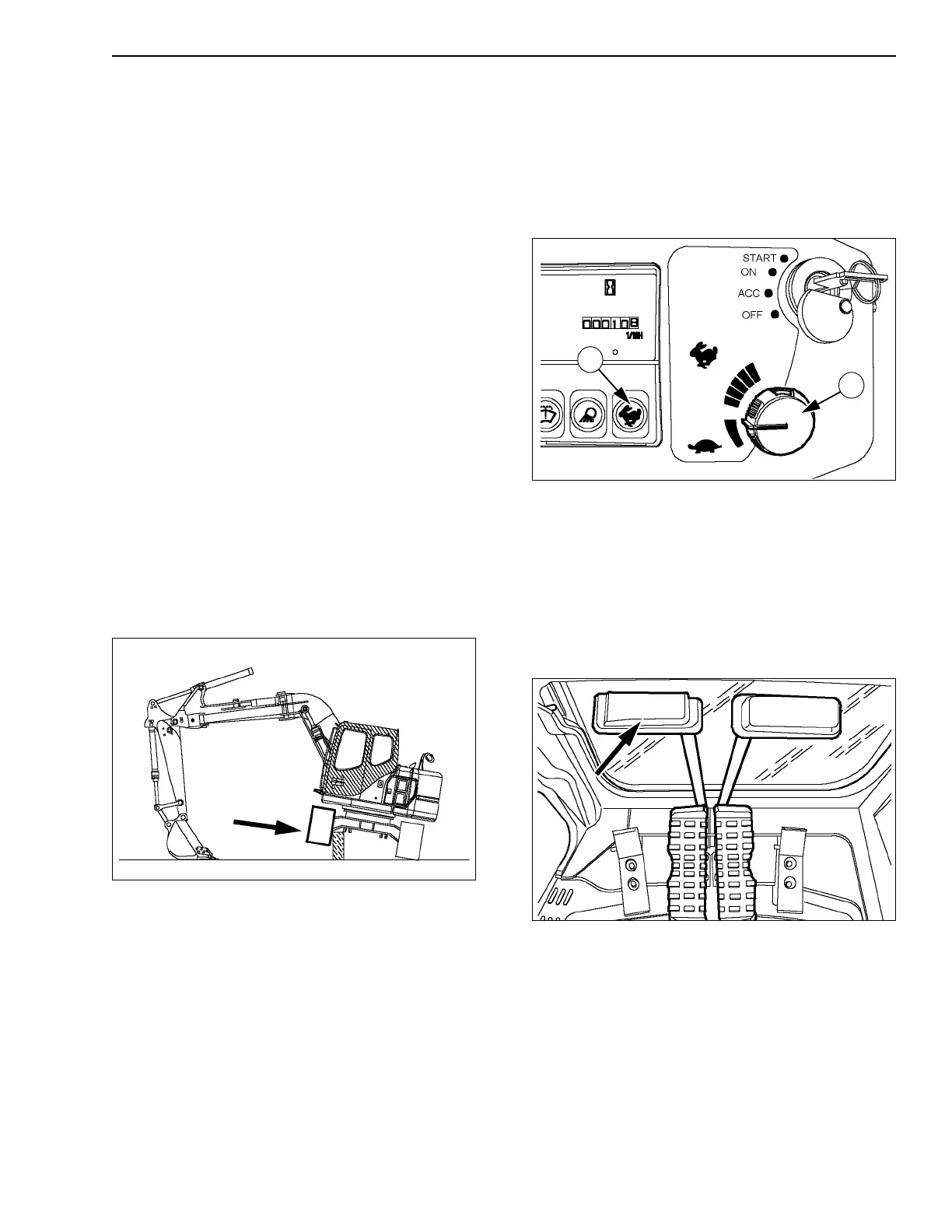

1. Place the upperstructure at right angles to the

undercarriage. Use the attachment to press on

the ground and lower the boom until the track is

raised off the ground.

CT02D176

Figure 1

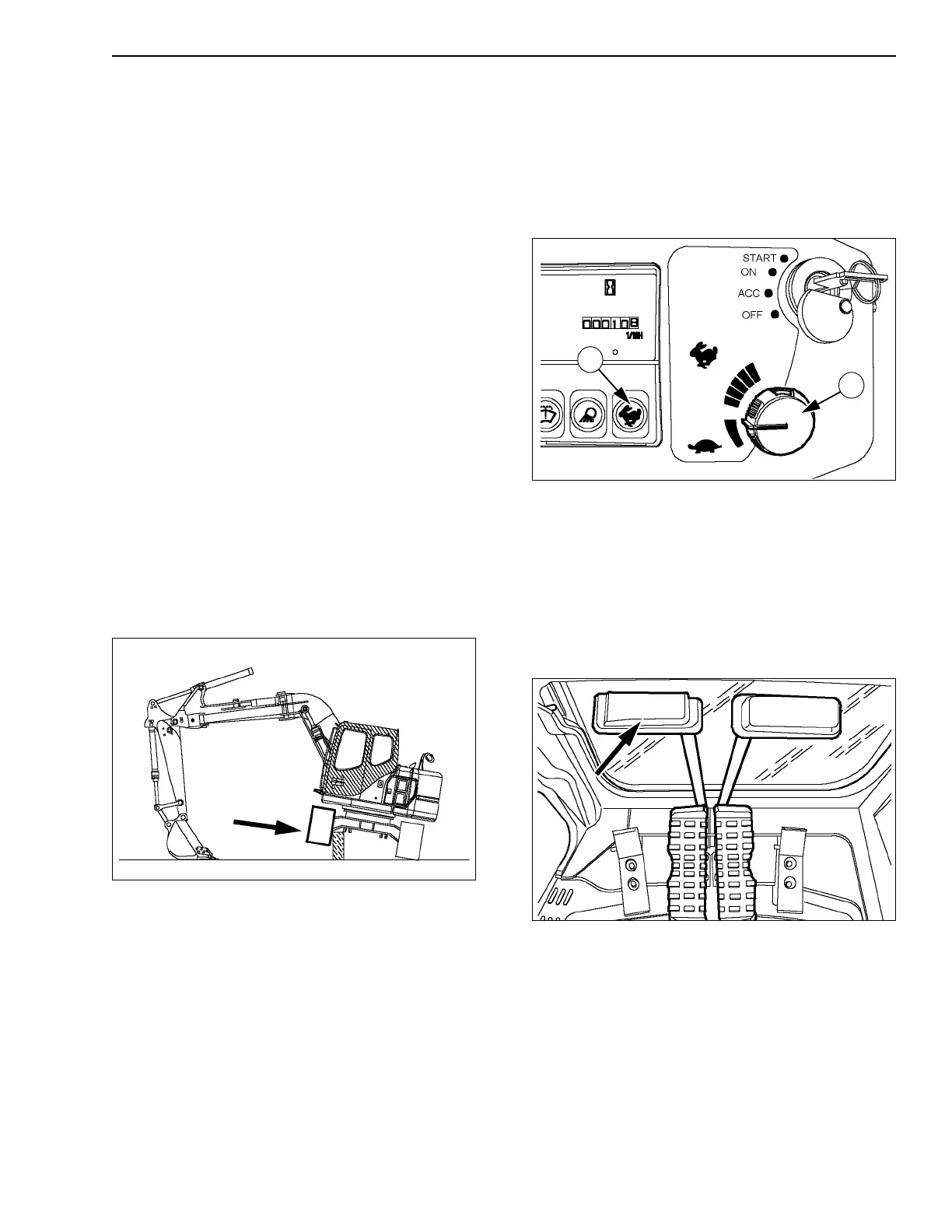

2. Put the engine throttle button (1) on the

maximum speed position and select the fast

speed (2).

CT02D156

Figure 2

3. Operate the travel control lever for the raised

track forwards and then in reverse, to remove the

mud.

4. Repeat Steps 1 to 4 for the other track.

NOTE: For machines fitted with the dozer blade, the

machine can be lifted by completely lowering the

blade and by using the attachment as a support on

the ground, opposite the blade.

CT02C063

Figure 3

CHECKING THE TENSION

1. Park the machine on flat, horizontal ground.

2. Clean the tracks.

3. Place the upperstructure at right angles to the

undercarriage. Use the attachment to press on

the ground and lower the boom until the track is

raised off the ground.

1

2

Loading...

Loading...