CEL-712 Microdust Pro Real-time Dust Monitor

27 Casella Measurement

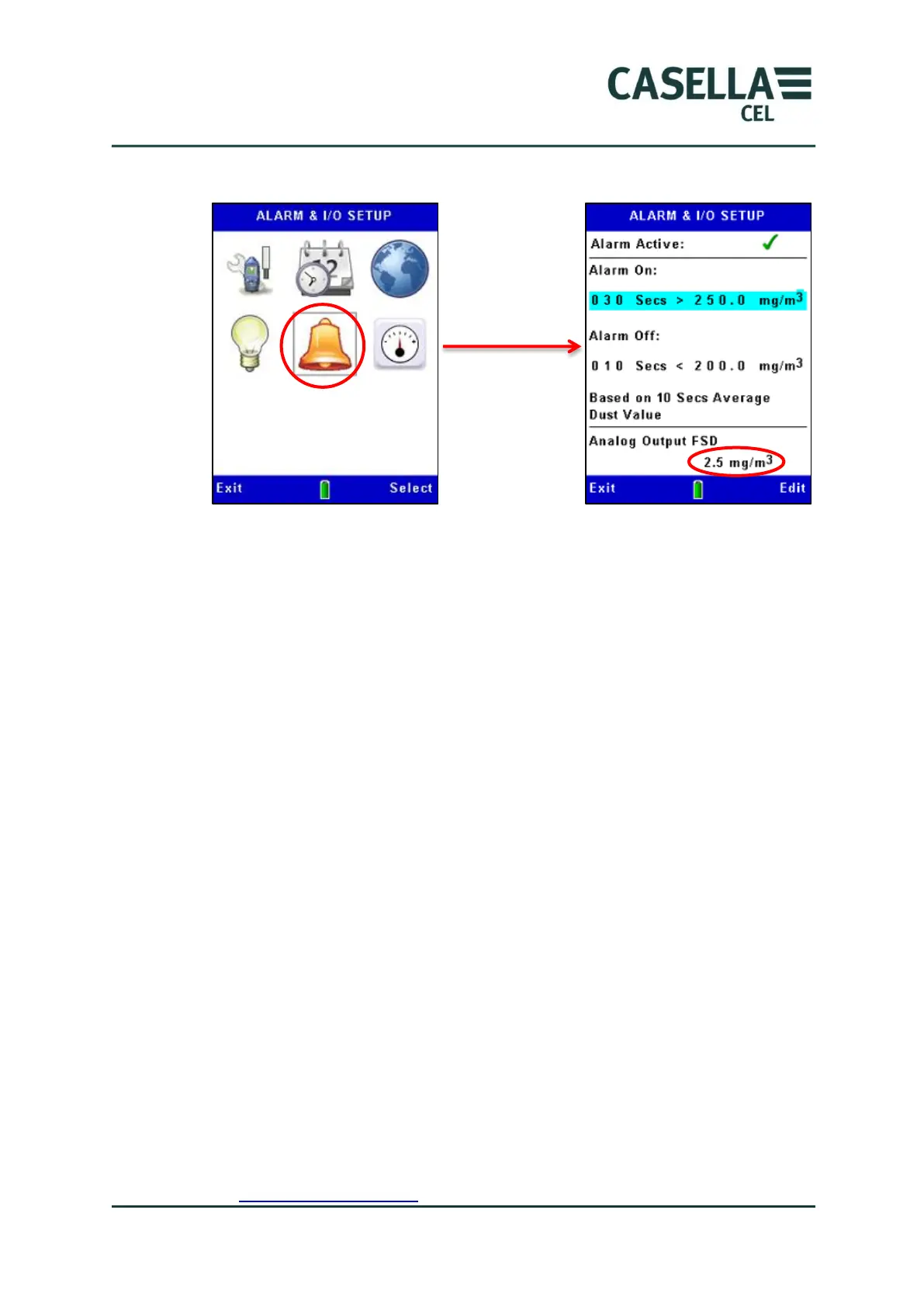

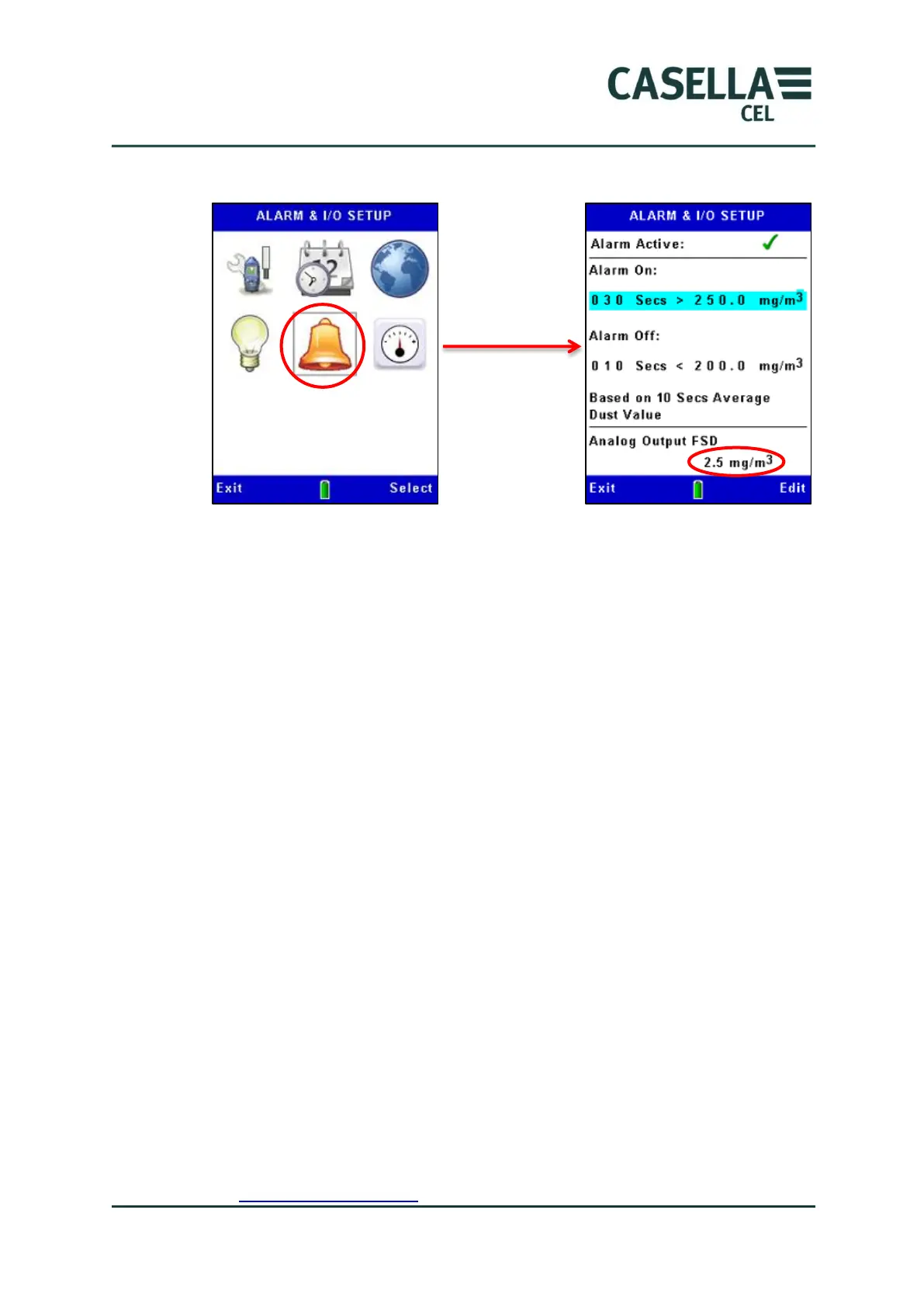

Figure 12 Analog setup

3.11 Checking the instruments Zero and Span

The Microdust Pro is a sensitive measuring instrument. Prior to making

measurements and to ensure optimum accuracy, it is recommended that the

user performs a ‘Zero’ and ‘Span’ check.

The Microdust Pro is supplied with an optical ‘Calibration Insert’ which is used

to establish a known instrument sensitivity or ‘Span’ .

When inserted into the probe, the Calibration Insert creates a stable and fixed

scattered effect and signal level. Following the default factory calibration

(using Arizona Road Dust equivalent - ISO 12103 -1 A2 (fine) test dust) the

Calibration Insert will produce a light scattering effect which is equivalent to a

factory dust concentration level as shown on the filter label.

Calibration Inserts and probes are supplied as matched pairs, always ensure the

correct Insert is used for a given probe.

It should be noted that all optical dust sensing instruments such as the

Microdust show a sensitivity to different particulate types due to differences in

particle size distribution, material refractive index, particulate shapes and

colours. For a given measurement application and dust type, the instrument

may show a response different to the factory calibration conditions.

For a given monitoring application (i.e, a specific dust type and conditions) the

optimum accuracy of the real time dust measurement is achieved by

establishing a calibration factor. A specific ‘dust type’ calibration factor is

derived by the comparison of the Microdusts real time measurement to a co-

located gravimetric result (i.e using a pump and filter system). Please refer to

the Gravimetric Calibration section on page 33.

Loading...

Loading...