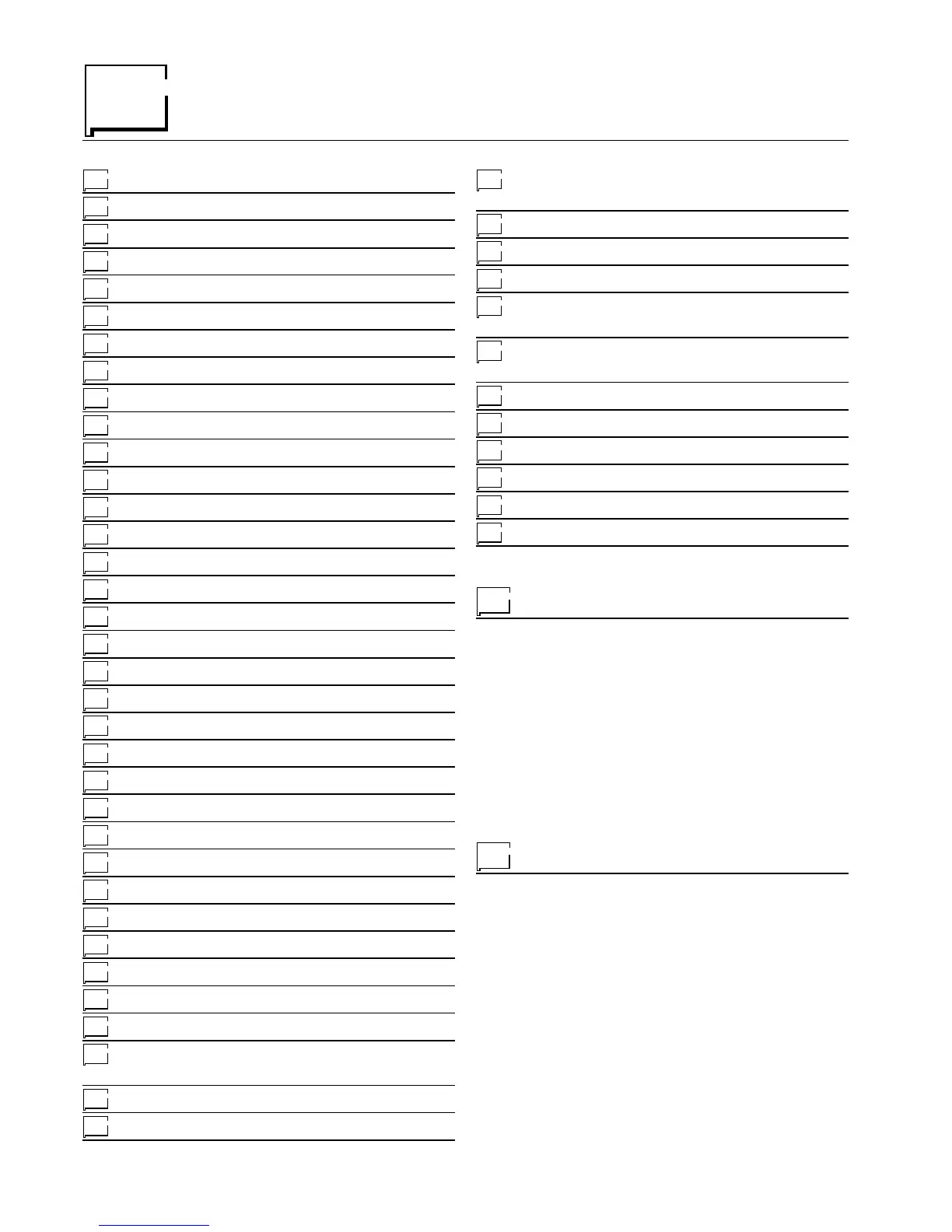

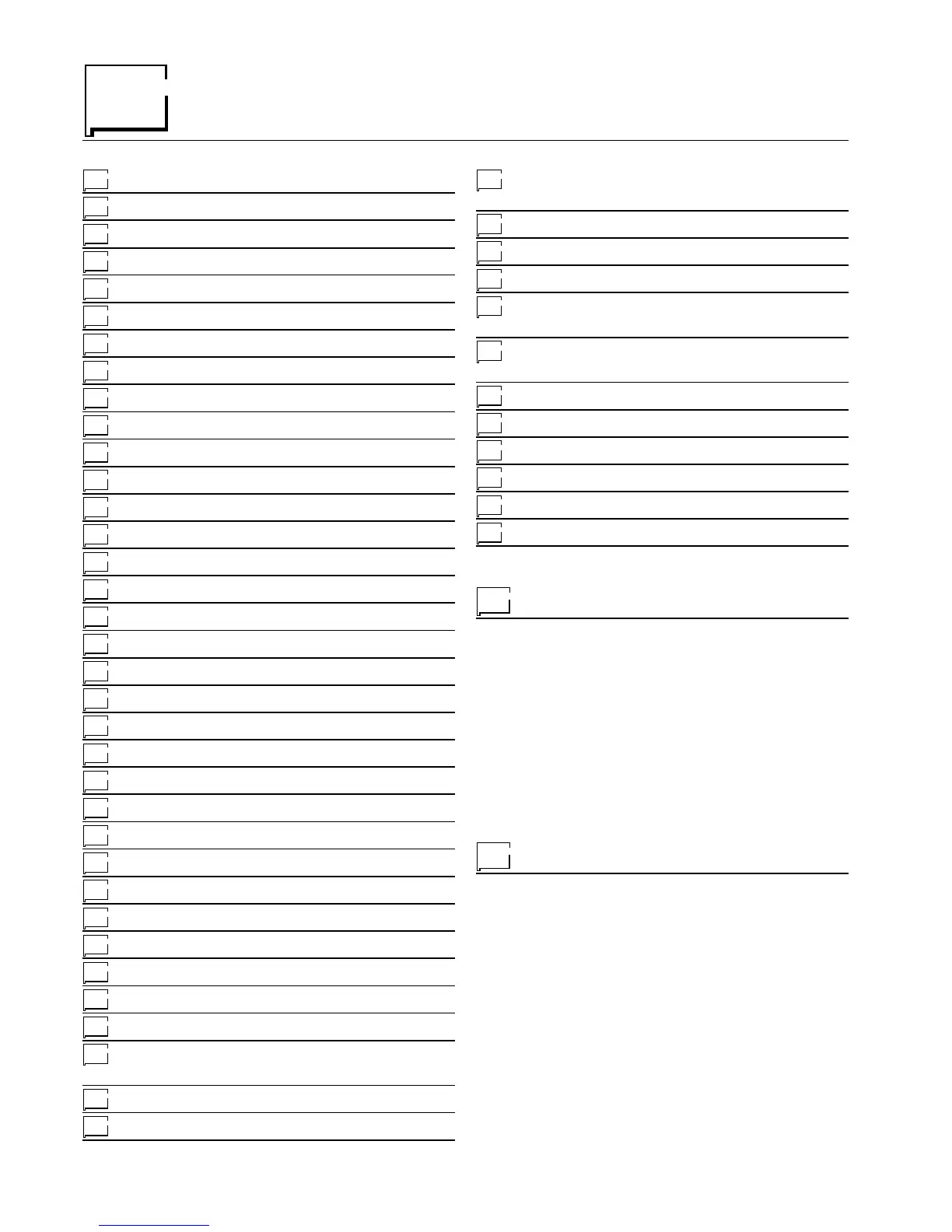

22

ENGLISH

EN

Introduction 22

Description 22

Technical data 23

Operating features 23

Usage limits (IEC 60974-1) 24

How to lift up the system 24

Opening the packaging 24

Installation and connections 24

Loading wire 28

Assembly of drive rolls for steel 28

Assembly of drive rolls for aluminium 28

Command and control units DIGITECH 400 PULSED 29

Command and control units TA4 29

Control panel DIGITECH 400 PULSED 30

Control panel TA4 33

Adjustment from generator or wire-feeder 34

Viewing installed software versions 34

Before welding 34

Welding procedures 34

Create and memorize new automatic welding spots 37

Call up automatic spots memorized beforehand 37

Copy and change automatic welding spots 37

To delete an automatic welding point 37

How to use automatic welding spots 37

Welding sequence 37

Resetting 38

Limits to changing parameters 38

"ENERGY SAVING" function 38

Aluminum welding 38

Maintenance 39

Remote controls and accessories 39

Error conditions 40

The pointing out of any difficulties

and their elimination 41

Replacing front electronic circuit boards 41

Wiring diagram DIGITECH 400 PULSED 86

Key to the electrical diagram

DIGITECH 400 PULSED 88

Colour key 88

Wiring diagram TA4 90

Key to the electrical diagram TA4 91

Meaning of symbols written on the DIGITECH 400

PULSED generator and on the TA4 wire-feeder 92

Meaning of graphic symboles on rating plate

(DIGITECH 400 PULSED) 93

Meaning of graphic symboles on rating plate (TA4) 94

Spare parts list (DIGITECH 400 PULSED) 95-99

Spare parts list (TA4) 100-103

Complete entrainment mechanism with 4 rolls 104

Drive mechanism 106

Ordering spare parts 107

Introduction

Thank you for having purchased our product. Please read instruc-

tions on use in this manual as well as the safety rules given in

the attached booklet and follow them carefully to get the best

performance from the plant and be sure that the parts have the

longest service life possible. This manual will show you the best

way to do any maintenance jobs or repairs eventually needed by

your plant to resolve any eventual problems, we do however rec-

ommend our customers to arrange to have maintenance and even-

tual repairs done at our servicing centres as they have the right

equipment and the highly qualified personnel is constantly updated.

All our machinery and systems are subject to continual develop-

ment. We must therefore reserve the right to modify their construc-

tion and properties.

Description

The synergic multifunction DIGITECH 400 PULSED power source,

based on the most modern IGBT based inverter technology with

digital control, allows high quality welding both in MIG/MAG and in

Pulsed MIG on all materials and particularly on stainless steel, alu-

minium and galvanized steel, by minimizing any reworking job af-

ter welding thanks to its spatter free performance.

Technologically advanced, robust and easy-to-use, DIGITECH 400

PULSED represents the ideal solution for any application requiring

high precision and repeatability of the achieved results, by making

this power source particularly suitable for the most qualified jobs in

any industrial application. The high versatility of DIGITECH 400

PULSED also achieves optimal performances both in TIG by "lift"

mode striking and in MMA welding.

The TA4 wire-feeder was designed for using all types of wire, ei-

ther solid or cored, and must only be used as part of the welding

generator and not for improper or any other use.

Loading...

Loading...