23

Technical data

The general technical data of the system are summarized in table

1 and 2.

Operating features

DIGITECH 400 PULSED

The main feature of the welding unit DIGITECH 400 PULSED are:

• Innovative and user friendly design;

• Metallic main structure with shockproof plastic front frames;

• Robust handles built into the chassis;

• Control panel protected against accidental impact;

• Synergic digital control of all the welding parameters;

• BURN BACK control. At the end of each weld, in any condition

and with any material, the digital control ensures a perfect wire

cut, prevents the typical “wire globule” from forming and ensures

correct arc restriking;

• Spatter free exceptional welding characteristics in both MIG/MAG,

MIG Pulsed and MIG Dual Pulsed on any material and with any

gas;

• High welding performance in both MMA and TIG by "lift" mode

striking;

• Exclusive SWS "Smart Welding Stop" system at the end of TIG

welding. Lifting up the torch without switching off the arc will in-

troduce a slope down and it will switch off automatically;

• WSC Wire start control. This arc striking control device prevents

wire from sticking to the workpiece or torch nozzle and ensures

precise and smooth arc striking, particularly when welding alu-

minium;

• WFC Wave form control. Both welding parameters and pulse

wave form, digitally controlled by the microprocessor, are moni-

tored and modified every few microseconds in order to keep the

arc constantly precise and stable by compensating for continu-

ous changes in welding conditions caused by torch movement

and workpiece irregularity;

• Ability to store personalized welding programs;

• Monitoring and repetition of welding parameters;

• User friendly and easy-to-use selection and recalling of the pa-

rameters and welding programs;

• Low energy consumption;

• "Energy Saving" function to operate the power source cooling

fan and the torch water cooling only when necessary;

• Remote parameter adjustment directly from TA 4 feeder;

• Auto-diagnostic feature for trouble shooting;

• Password-controlled total or partial equipment access;

• Initial and crater welding cycle control;

• With the special MIG torches you can adjust the welding param-

eters at a distance straight from the torch.

TA4

The main feature of the wire feeder TA4 are:

• Cast aluminium wire feeder with 4 large size rolls for precise and

constant wire feeding;

• Welding current SYNERGIC adjustment;

• Arc length FINE adjustment;

• Use of Push-Pull guns optional;

• Wire test;

• Gas test.

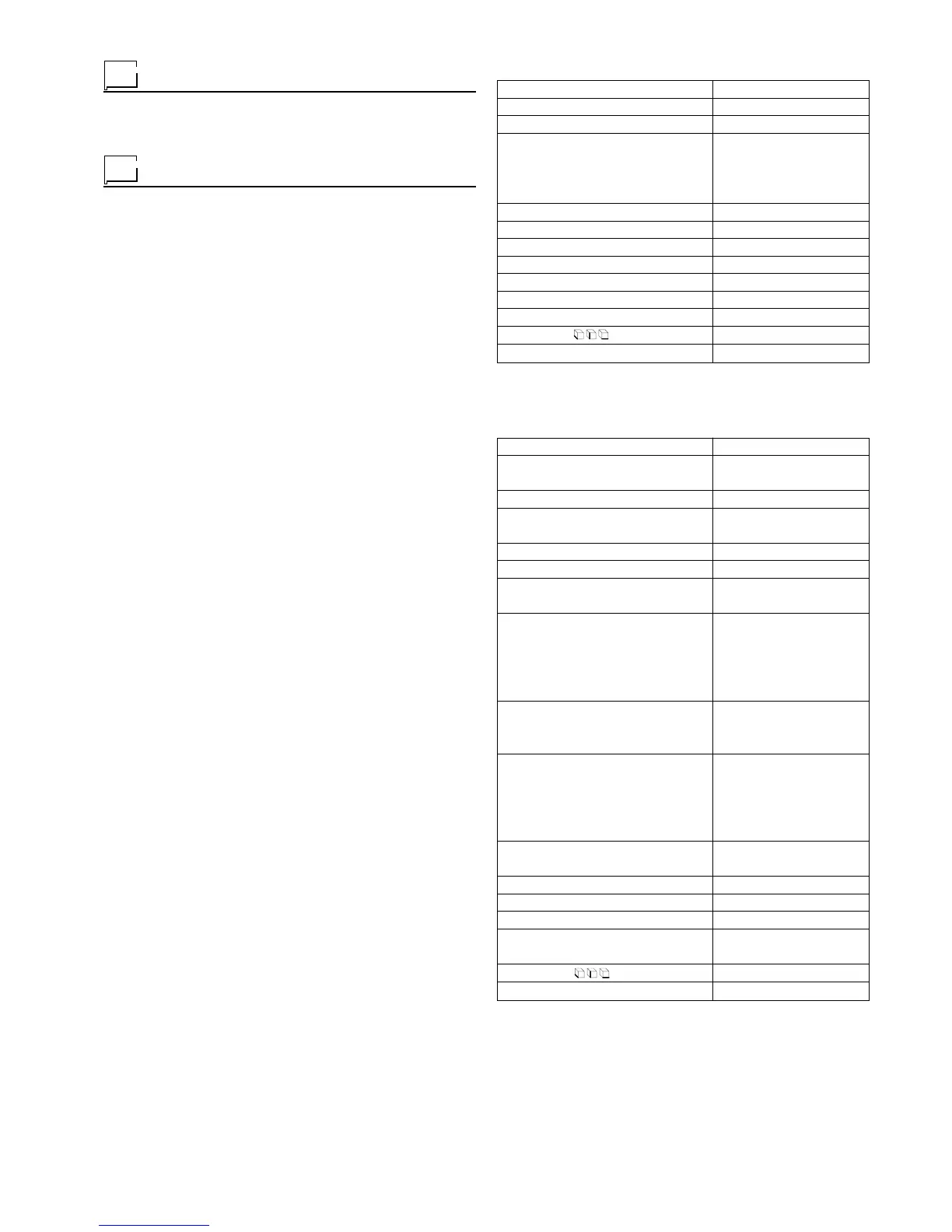

Model

Three phase feeding 50/60 Hz

Power supply: Z

max

Current range

MIG MAG

TIG

ELECTRODE

Installation power

Open circuit voltage

Duty cycle at 100%

Duty cycle at 60%

Duty cycle at 50%

Insulation class

Protection class

Dimensions

Weight

V

ohm

kVA

V

A

A

A

mm

kg

DIGITECH 400 PULSED

400

(*)

10–400 A / 14,5-34 V

10–400 A / 10,5-26 V

10-400 A / 20,5-36 V

14,5

63

270

350

400

F

IP 23

665-525-290

48

Table 1

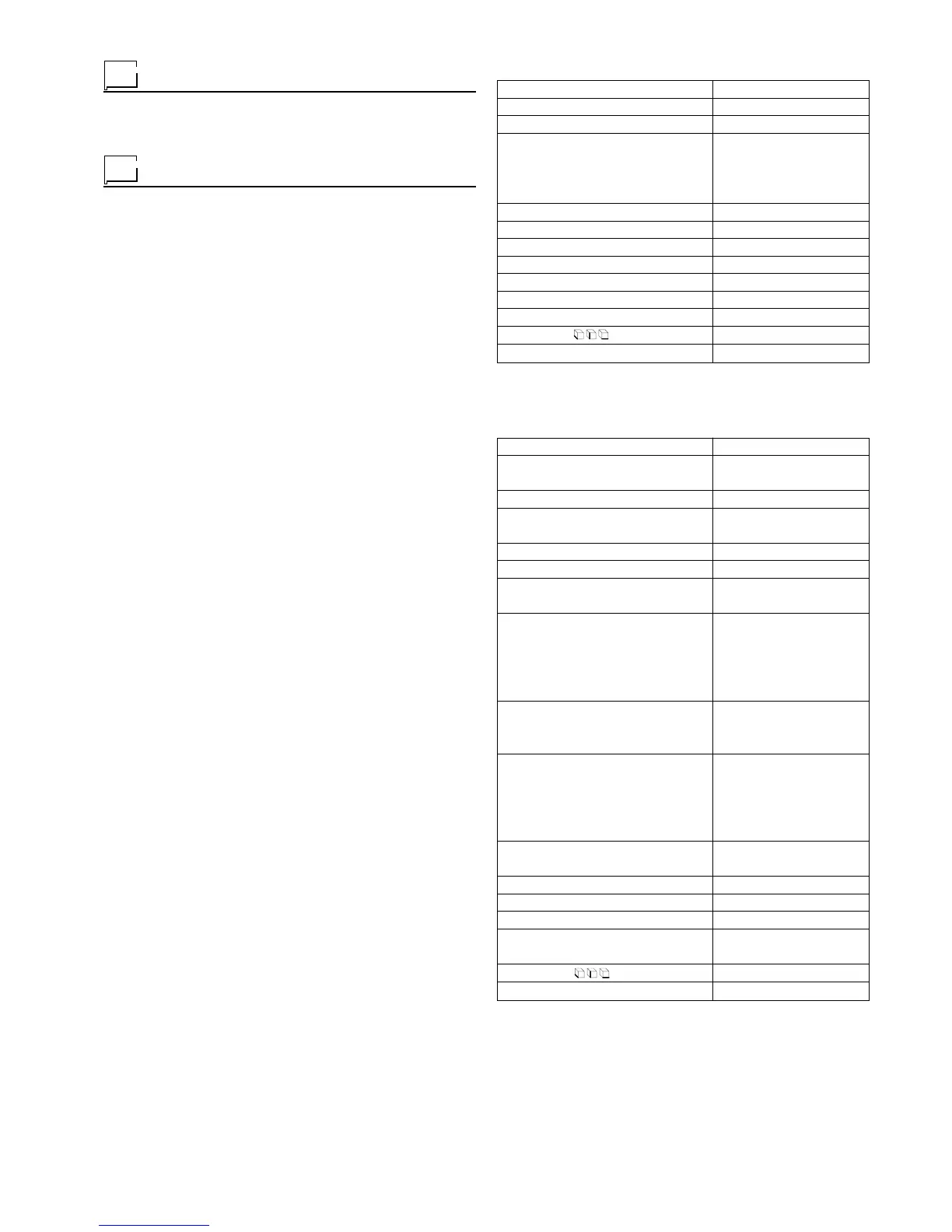

Model

Input voltage

of feeder

Rated frequency

Power output

of feeder motor

N° rolls

Wire diameter

Rated wire

feeding speed

Compatible wire types

Spool

Diameter

Weight

Protection gas

Coolant

Maximum pressure

Duty cycle at 60%

Duty cycle at 100%

Insulation class

Motor and control protection

grade

Dimensions

Weight

V

Hz

W

mm

m/min

Ømm

kg

bar

A

A

mm

kg

TA4

48

50-60

100

4

0,8-2,4

0,5-22

• Carbon steel

• Stainless steel

• Aluminium magnesium

• Aluminium silicon

• Basic and rutile cored wires

300

20 (max)

• Carbon dioxide

• Pure Argon

• Argon-Carbon dioxide-Oxygen

• Argon and

Carbon dioxide blends

Distilled water

3,5

600

460

F

IP 23

570-400-275

17

Table 2

(*) IMPORTANT: This system, tested according to EN/IEC 61000-

3-3, meets the requirements of EN/IEC 61000-3-11.

Loading...

Loading...