8

ENGLISH

Introduction

Thank you for purchasing one of our

products. Before using the equipment

you should carefully read the instruc-

tions included in this manual. In order to

get the best performance from the

system and ensure that its parts last as

long as possible, you must strictly follow

the usage instructions and the mainte-

nance regulations included in this

manual. In the interest of customers,

you are recommended to have mainte-

nance and, where necessary, repairs

carried out by the workshops of our ser-

vice organisation, since they have suita-

ble equipment and specially trained per-

sonnel available. All our machinery and

systems are subject to continual deve-

lopment. We must therefore reserve the

right to modify their construction and

properties.

Descrizione

Built according to the very latest

IGBT

based inverter technology, these DC

power sources thanks to their excellent

arc characteristics, are recommended

for highest standard applications with

any electrode. Suitable to be used in shi-

pyards, steel construction, pipe welding

and maintenance,

MATRIX 250 E

ensure an extraordinary stability of the

welding parameters and their "fast dyna-

mic characteristic" enables to achieve

quality results even with the most diffi-

cult cellulosic and basic electrodes.

MATRIX 250 E

also allows the possibi-

lity of

TIG

welding with

"lift"

mode arc

striking.

FEATURES

• Excellent welding characteristics with

any type of electrode, including cellu-

losic;

• Reduced weight and size, easy-to-

carry;

• Adjustable”arc force”;

• Innovative and compact design;

• Metallic main structure with shock-

proof plastic front panel;

• Control panel protected against acci-

dental impact;

• Robust handle integrated into the

chassis;

• Sloping front panel, easy to read and

adjust and highly visible from any

direction;

• IP 23 protection class and dust-proof

electronic components, thanks to the

innovative "Tunnel" fan cooling

system, allow operation in the tou-

ghest work environments;

• Automatic

"hot start"

to improve the

arc striking with the most difficult

electrodes;

•Electrode

Antisticking

function;

• TIG welding with thermal controlled

(TCS)

"lift"

type striking reducing tun-

gsten inclusions to a minimum and

allowing to also strike on sharp edges;

• The generator also conforms to all

European Union standards and direc-

tives in force.

Introduction 8

Descrizione 8

Technical data 9

Usage limits (ISO/IEC 60974-1) 9

Safety standards 9

Installation 10

Connection to the

electrical supply 10

Norme d’uso 10

Connection of the

welding cables 11

Prior to welding 11

Maintenance 11

The pointing out of any difficulties

and their elimination 12

Adjustment of electronic circuit

board 75

Wiring diagram 76

Key to the electrical diagram 77

Colour key 77

Meaning of graphic symbols on

machine 82

Meaning of graphic symboles on

rating plate 84

Spare parts list 86-88

Ordering spare parts 90

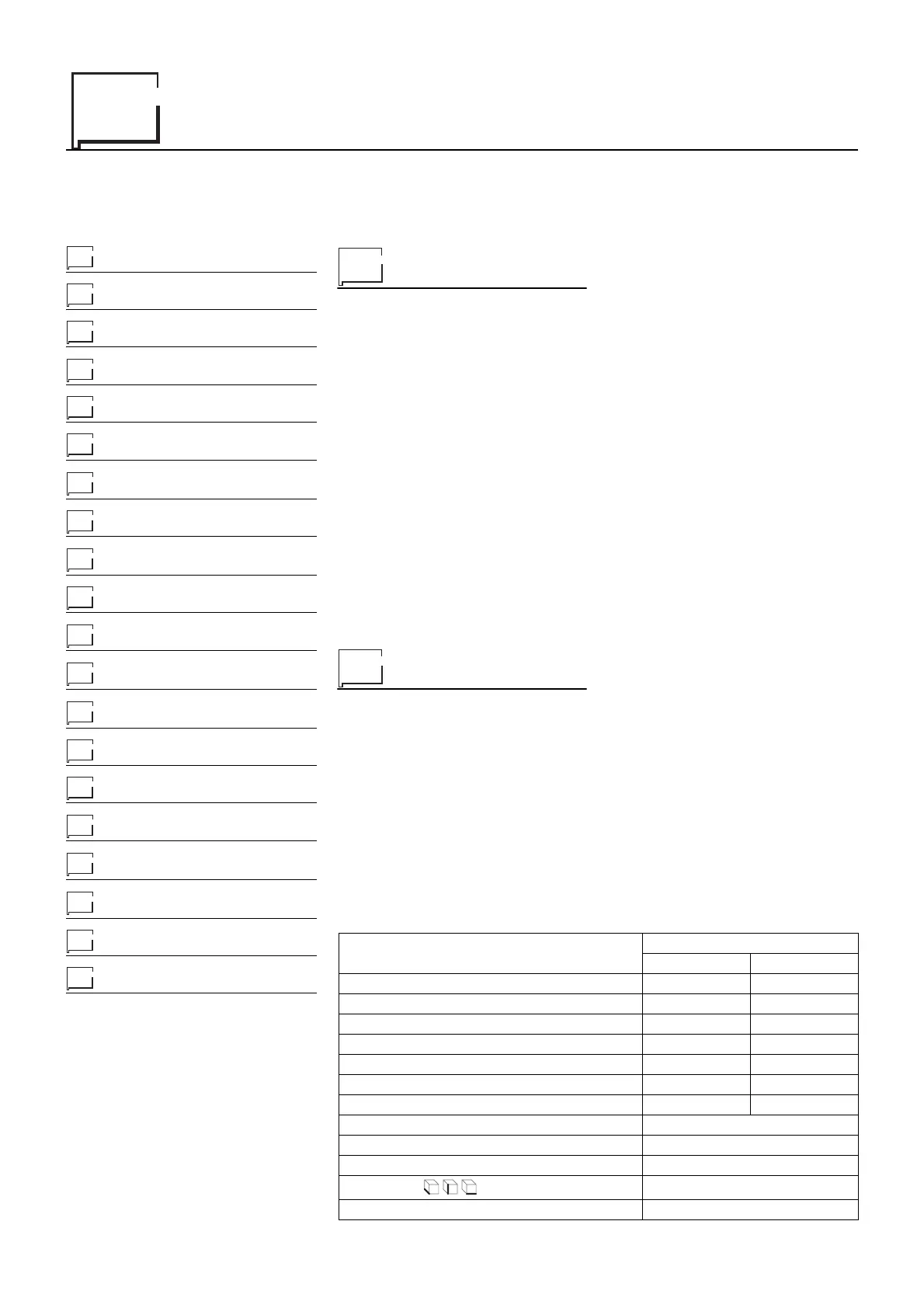

Table 1

Model

MATRIX 250 E

TIG DC MMA

Three phase feeding 50/60 Hz V 400 400

Adjustment field A 5 ÷ 250 5 ÷ 250

Maximum potential kVA 7 7

Secondary idle voltage V 95 95

100% usable current A 170 160

60% usable current A 200 200

35% usable current A 250 250

Usable electrodes 1,6 ÷ 5

Insulation class H

Protection class IP 23

Dimensions

mm 500-425-220

Weight kg 19

UK

Loading...

Loading...