page 25 www.centsys.com

SECTION 7

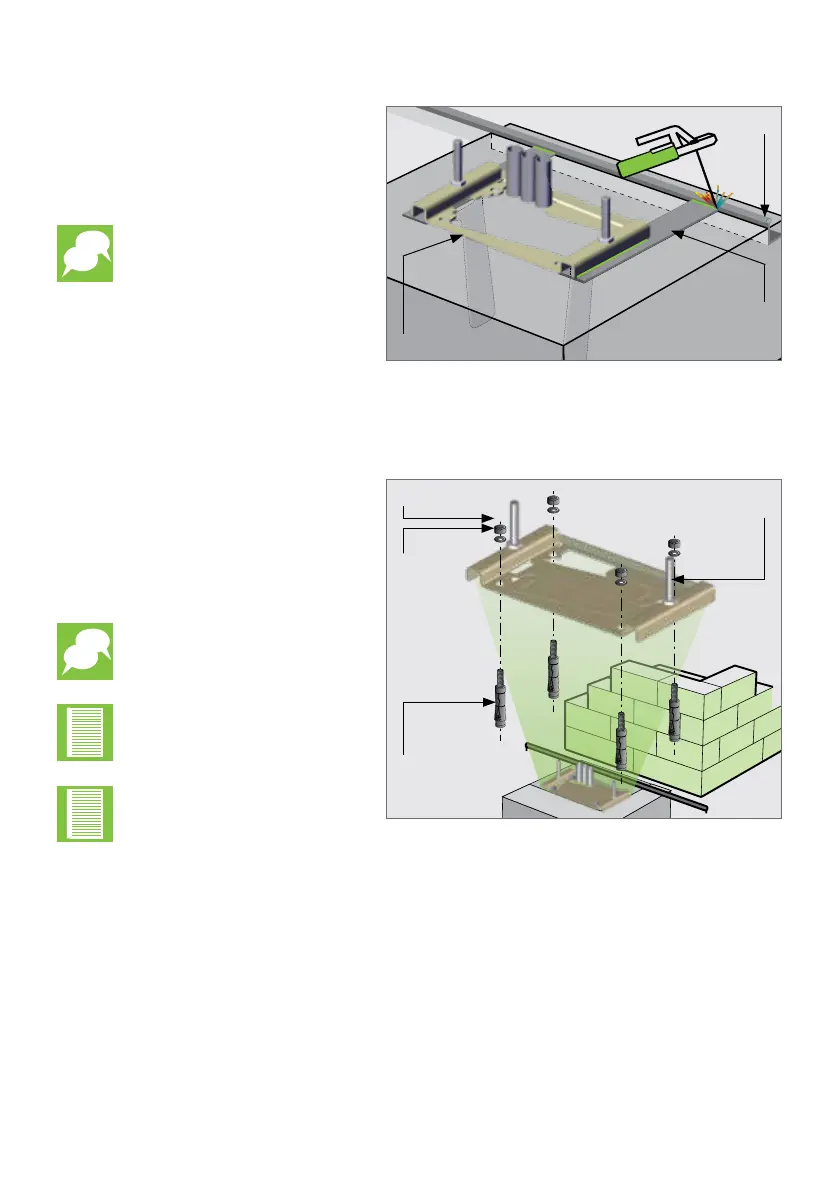

FIGURE 20

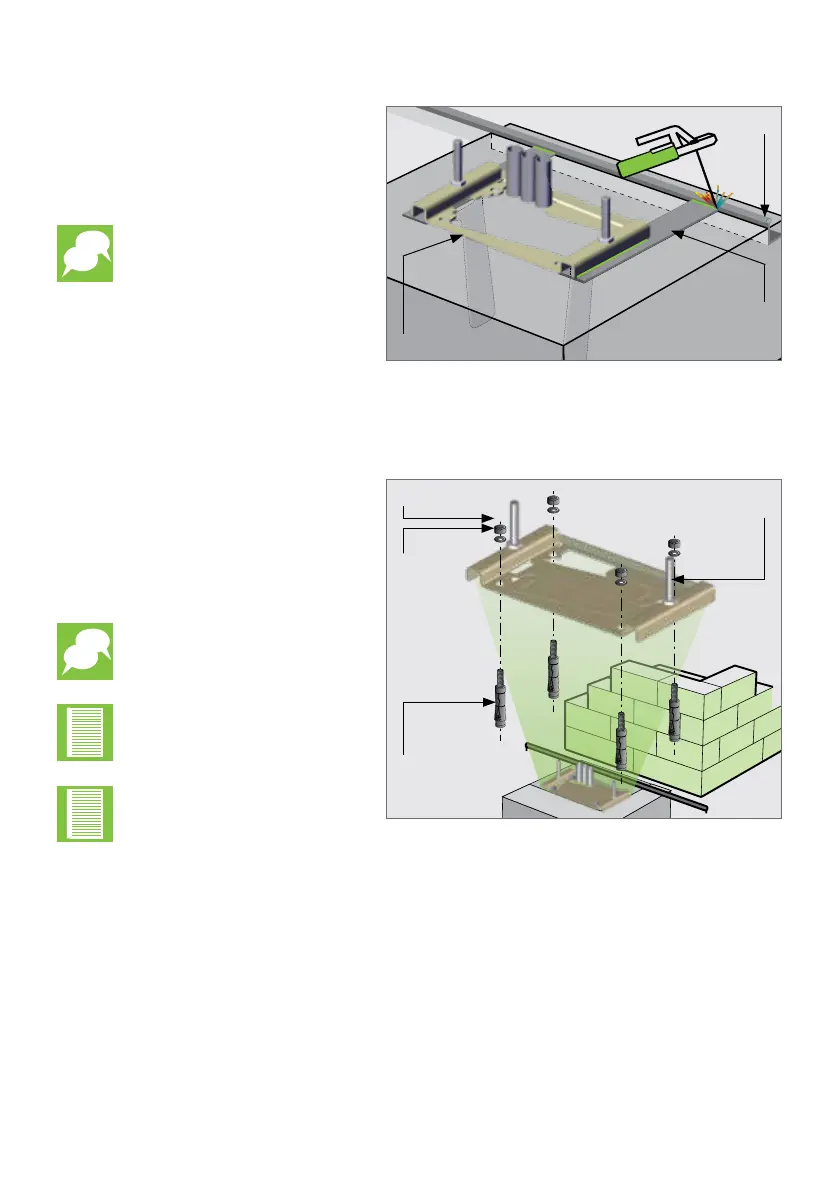

FIGURE 21

When using a concrete

foundation, it is

recommended that the

Foundation Plate is welded

to the rail/track of the gate

using a short length of at

bar, as shown in Figure 20.

This makes it possible

to complete the whole

mechanical and electrical

installation without having

to wait for the concrete to

set. After completing the

installation, the concrete

can be poured and the

operator left in Manual

Mode until the concrete

has set. Do not operate the

motor until concrete has

completely set.

Flat bar welded to

Foundation Plate

and rail

Foundation Plate

Rail

7.1.4.2. Existing Concrete Plinth

Nut

Washer

Mounting

Bolt

Expansion Stud

OPERATOR INSTALLATION

If bolting onto an existing concrete

plinth, place the Foundation Plate

down in the correct position and use

the plate as a template for marking

the Expansion Stud holes.

Rerouting of existing cables

may be necessary.

Ensure that the Expansion

Studs do not protrude more

than 23mm above the

Foundation Plate.

Check that the M10 half-

nuts are tightened to 20Nm

on the mounting bolts.

7.2. Retro-t Installations (Existing Sites)

The D10 SMART / D10 Turbo SMART has been designed to retro-t into existing D10

and D10 Turbo installations.

If the existing Foundation Plate is in a good condition, it is not necessary to replace

it with a new D10 SMART / D10 Turbo SMART Foundation Plate. However, if the

existing Foundation Plate is corroded or needs to be replaced for whatever reason,

the D10 SMART / D10 Turbo SMART Foundation Plate can accommodate the existing

footprint without the need to re-route cable conduits.

The D20 SMART is designed to t existing foundation plates for D10 and A10

installations. However, there are potential sites where an A10 was mounted high on a

foundation plate, and the D20 SMART will not be able to reach the rack.

In these cases, the rack will need to be lowered.

Loading...

Loading...